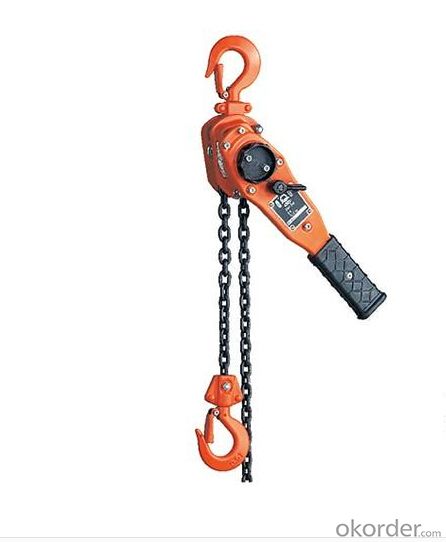

10t heavy duty Explosion-Proof Chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HBSQ10T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 10tons

Maximum Lifting Height: 3M

Lift Speed: same with pulling speed

Certification: CE,GS and ISO9001

Warranty: one year

After-sales Service Provided: No overseas service provided

Capacity: 10 tons

Standard lift height: 3M

Running test load: 10TONS

No.of falls of load chain: 4

Net weigth: 83kg

Color: cooper color

Description: cooper chain hoist

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

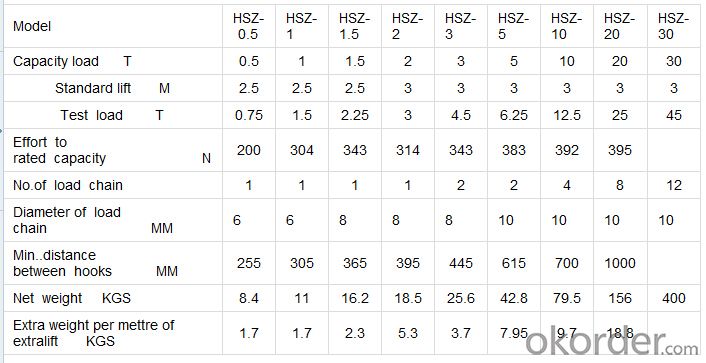

Parameter List

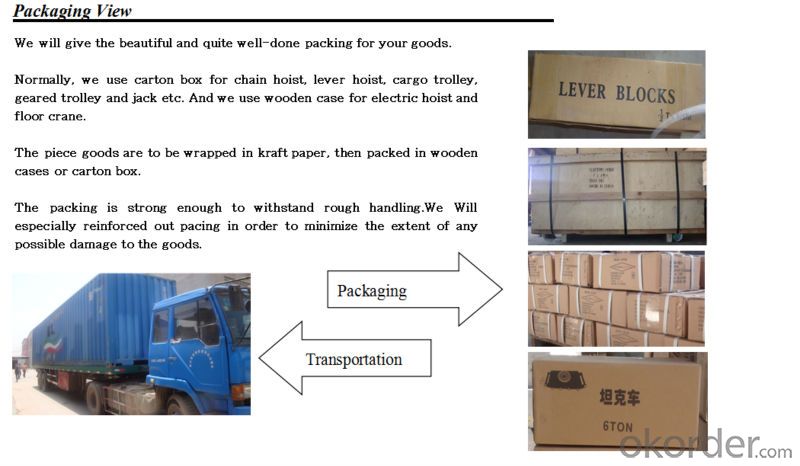

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service.

3. Fast delivery time.

4. We have CE, ISO9001 and GS certification.

FAQ

1.What’s your product range?

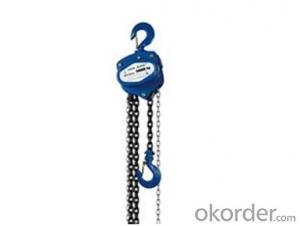

Electric Hoist: electric chain hoist , electric wire rope hoist, mini wire rope electric hoist, mini electric chain hoist.

Manual Chain Hoist and Lever Hoist Chain , Trolley , Jack,Lifting Strap,Cable Pulley, hand pallet truck,etc.

2.When Can I get the quotation?

We usually quote within 24 hours after we get your inquiry . If you are very urgent to get the price , please tell us in your email so that we will regard your inquiry priority.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, you need pay the express fee ,

4.What information should I let you know if I want to get a quotation?

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- A steel wire rope is a common wire rope, and a sling is a special tool for lifting some goods. The sling is a sling tool made of wire ropes

- Q: What are the dangerous sections of the crane hook?

- The sling tension A-A section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The use of wire rope in the atmospheric environment, mainly caused by the failure of wire rope is fretting fatigue, at present, the wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese treatment, wear resistance, enhance the surface of steel wire that is not easy to wear and corrosion resistance of the fatigue life is greatly improved

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: What are the specifications for the rigging?

- The wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese wear-resistant steel wire surface treatment, corrosion resistance to enhance, not easy to wear and corrosion fatigue life of the steel wire rope large increase, fatigue life is three as structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue test machine if they have on their own to do comparative tests, this test results most credible, the service life of wire rope and the fatigue life is directly proportional to the fatigue life, long service life with the proportion of prolonged use of lower cost, better stability, phosphating coating of steel wire rope is patent technology production

- Q: Notice of tower crane?

- When the wind is above four, no lifting, installation or disassembly shall be carried out. Check the connection of all parts of the hydraulic jacking system before jacking up. No swing arm and other operations are prohibited during jacking.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

Send your message to us

10t heavy duty Explosion-Proof Chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords