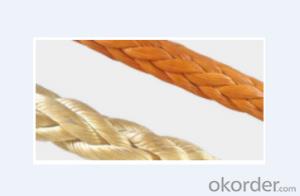

Mooring Rope,material: polypropylene, polyester, nylon, High Molecular Polythylene , aramid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mooring Rope

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, High Molecular Polythylene (UHMWPE), aramid fibre and synthetic fibre. Diameter scope: Φ6mm ~ Φ140mm are available.

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easyto operate, etc. Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Textile Sling

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc.

The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope and traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene material). We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- A sling is also called a jack rope, a pair of rope or rope buckle. Hoisting works are more used, such as tying equipment, hanging blocks, stabilizing winches and so on. The utility model has the advantages of good quality and large elasticity, but the rigidity is large, and the bending is not easy, and once the bend is not easy to recover. Slings made of wire ropes of hemp core are not easy to work under high temperature.

- Q: Where should I pay attention to the formwork?

- In the case of cast in place multi-storey houses and structures, the method of segmental formwork shall be adopted, and the upper formwork and its support shall be installed and shall meet the following requirements:The lower floor shall bear the load-bearing capacity of the upper layer or support with the support;The column of the upper bracket shall be used for the column of the lower layer bracket and the padding plate shall be laid;When the suspension formwork and truss formwork method are adopted, the supporting capacity and stiffness of the supporting structure must meet the requirements.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- My understanding is different. The cable refers to the cables used for power supply or the cables used for hanging lamps.

- Q: Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

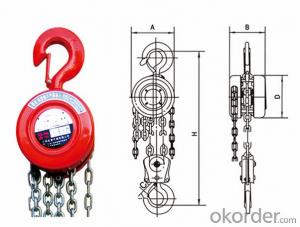

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What's the catch?

- The type of slings 1. slings are mainly metal slings and synthetic fiber slings in two main categories. 2. metal slings are mainly wire ropes, slings, chains, slings and so on. 3. synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

- Q: How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q: What are the installation steps for crane beams?

- Installation of crane beam elevation as a negative deviation, between surface and column bracket crane beam flange into the iron plate. But the shim shall not exceed three layers and shall be placed under the end of the crane beam or under the stiffener, and the area of the shim shall not be less than 60% of the part of the contact area between the crane beam and the bracket.

- Q: Notice of tower crane?

- When the wind is above four, no lifting, installation or disassembly shall be carried out. Check the connection of all parts of the hydraulic jacking system before jacking up. No swing arm and other operations are prohibited during jacking.

- Q: Types of slings for slings

- Slings are mainly made of metal slings and synthetic fiber slings in two main categories.

Send your message to us

Mooring Rope,material: polypropylene, polyester, nylon, High Molecular Polythylene , aramid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches