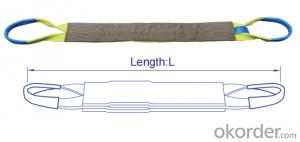

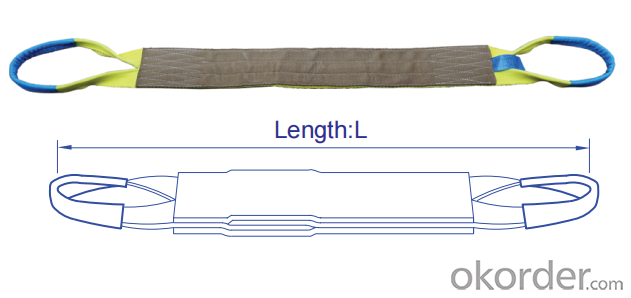

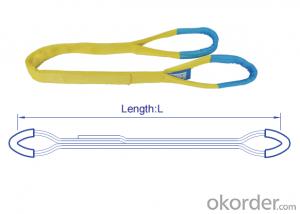

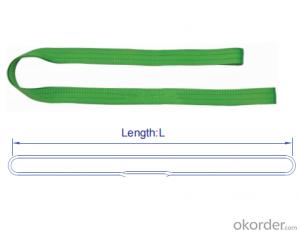

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

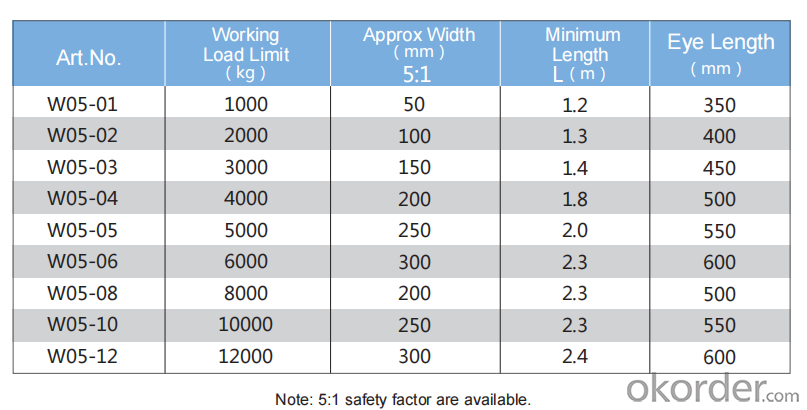

Specification

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Apply to oil pipelines, large diameter thin-walled pipe and products hoisting.

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

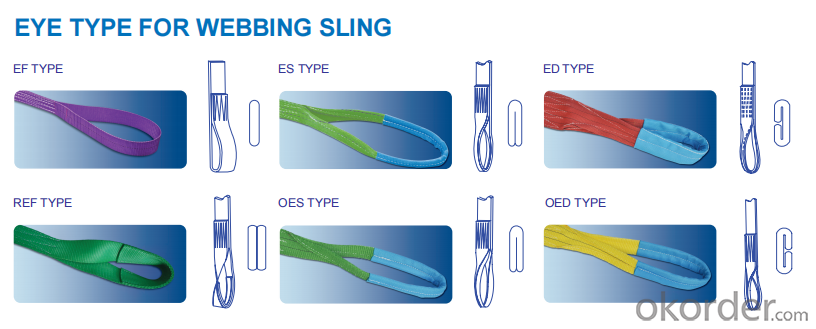

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:5 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q: What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: What is the name of the wire above the train?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q: What's the sling for a movie?

- Now the movie also used the wire, but the rope is made by thin steel wire, so as not to betray. WIA, commonly known as wire.

- Q: What are the precautions for rigging in hoisting works?

- When lifting heavy objects, heavy is prohibited to stand.

- Q: What are the selection principles for lifting cranes?

- It can adapt to the conditions of road, hoisting, plane layout and equipment, machines and tools, and give full play to its technical performance.

- Q: Is the sling the same thing as the rigging?

- This is not strictly divided, if not to say that the rigging refers to those parts of the spreader is rigging, such as rings, ring buckle, hook, shackle. The sling is a wire rope, lifting chain, lifting belt, these rigging consisting of a complete set for lifting tools, that is, sling. In practice, the two are inseparable. So they are generally called rigging companies. Hope to help you, which is the media, and have the opportunity, please welcome to interview our company.

- Q: Notice of tower crane?

- After the tower crane is installed, the whole machine should be inspected and adjusted, and shall be ready for delivery after passing the inspection in stages and through the whole machine. In the case of no load, the deviation of the verticality between the tower and the ground shall not exceed 4/1000.. The motor and hydraulic unit of the tower crane shall be carried out in accordance with the relevant provisions concerning the motor and hydraulic device.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: Types of slings for slings

- Metal slings are mainly wire ropes, slings, chains, slings and so on.

Send your message to us

Soft Wide Body Polyester Webbing Textle Sling Working Load 12T

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches