High Tensile Endless Eye Type Round Slings Customers Requiement Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Tensile Endless Type Round Slings Customers Requiement

It is made of Ultra High Molecular Weight Polyethylene fiber, the tensile of which is 3-4 times of polyester fiber. It is High modulus and low elongation type fiber and the proportion is 0.97g/cm³(lighter than water).

The performance of the fiber such as UV-resistant, shock - resistant, acid - resistant, corrosion - resistant, wear – resistant, etc. are all much better than other synthetic fibers.

Advantages: Small size, light weight, soft, safe, low elongation, UV-resistant, wear – resistant, shock - resistant, corrosion – resistant, non-conductive, anti- static, long servicae life.

Low-temperature performance is good, operating temperature range: -125 ℃ ~80 ℃ , the weight is 1/4 of common round sling and the diameter is 1/2 of

common round sling.

Certification: GS, CE, ISO

Customized support: OEM, ODM

Place of Origin: Hebei, China

Brand Name: j&L

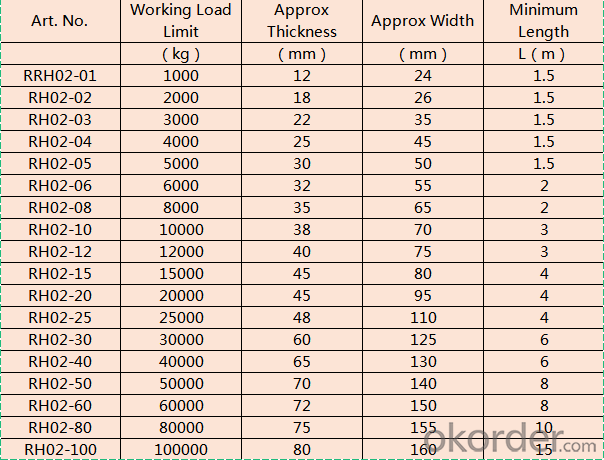

Model Number: R02

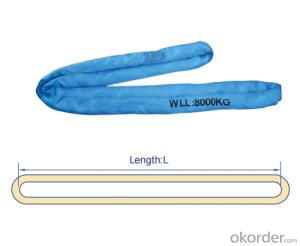

Type: Round Sling

Shape: Round

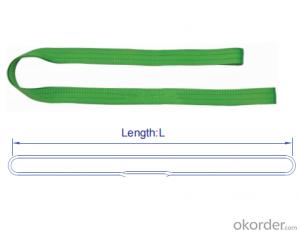

Sling Color: Green

Lifting Eye Type: Flat Eye

Color: Customers Require

Product name: Polyester Round Sling

Application: Lifting Goods

Safety factor: 5:1 6:1 7:1 8:1

Length: Customized Length

Width: Customized Width

Standard: CE/GS/ISO9001

Packing: Customers Requiement

MOQ: 1 Piece

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

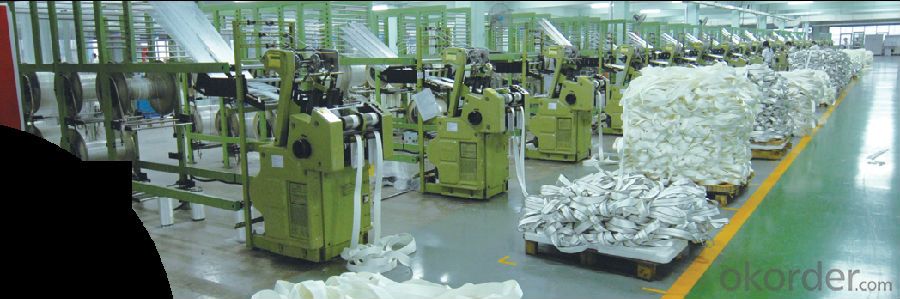

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

- Q: How much is the crane arm of the tower from the residential building recently?

- (1) the drivers and signaling personnel of the tower cranes must be specially trained and issued certificates by the relevant departments, and attention should be paid to whether the type of tower used by the driver is consistent with the actual tower type.(2) special person special plane management, Captain responsibility system, and strict shift shift system.(3) the newly installed or repaired tower crane must perform the machine test operation according to the specifications.(4) tower crane should keep a safe distance from overhead transmission lines.(5) driver's room should be equipped with fire extinguishing equipment.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q: How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q: Slings and rigging manufacturers, which cost-effective?

- Wire rope rigging, manganese phosphating coating steel wire rope is a new technology appearing in recent years. Wire rope has a long service life. Buy wire rope made of phosphating coating steel wire,

- Q: Is the sling the same thing as the rigging?

- This is not strictly divided, if not to say that the rigging refers to those parts of the spreader is rigging, such as rings, ring buckle, hook, shackle. The sling is a wire rope, lifting chain, lifting belt, these rigging consisting of a complete set for lifting tools, that is, sling. In practice, the two are inseparable. So they are generally called rigging companies. Hope to help you, which is the media, and have the opportunity, please welcome to interview our company.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 3. stainless steel wire rope, the use of stainless steel wire rope system, such as 304 or 316 stainless steel, the price is relatively expensive, the stainless steel wire for manganese phosphating coating (stainless steel wire need special phosphating phosphating formula), you can use the same life greatly extended.

Send your message to us

High Tensile Endless Eye Type Round Slings Customers Requiement Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches