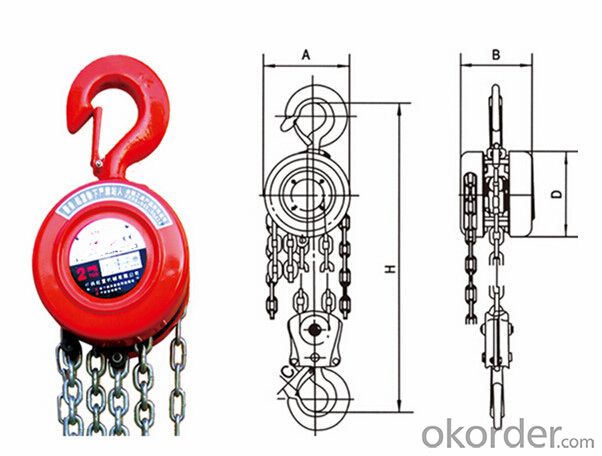

30Tons High Quality Manual Chain Block Chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name:CNBM

Model Number: VC-A30T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 45 tons

Maximum Lifting Height: 9M

Lift Speed: same with your speed

Certification: CE and GS

Warranty: one year

Rated Capacity: 30tons

Material: steel

Load Chain Diameter: 9MM

No. of load chains: 8

Net Weight: 220kg

Color: red or yellow

Description: 45 tons*3M VC-A chain block

Load chain diameter: 9mm

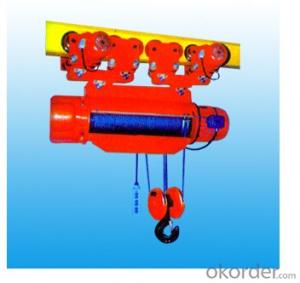

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

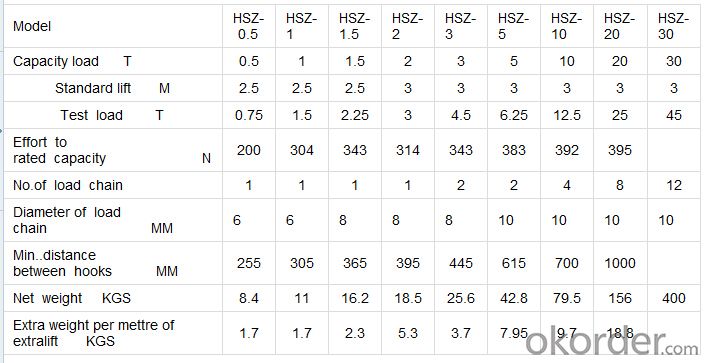

Parameter List

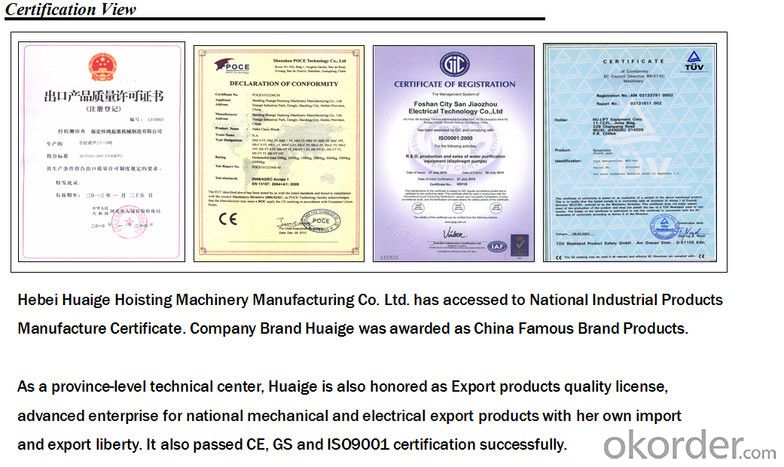

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service.

3. Fast delivery time.

4. We have CE, ISO9001 and GS certification.

- Q: What is the difference between cable stayed bridge and suspension bridge?

- Cable-stayed bridge, also called cable-stayed bridge, is a bridge that uses many cables to directly pull the bridge on the pylon. It is a structural system composed of a pressure tower, a tensile cable and a bent beam. It can be regarded as a multi span elastically supported continuous beam instead of a pier. The utility model can reduce the bending moment in the beam body, reduce the height of the building, lighten the weight of the structure and save the material.The cable-stayed bridge is composed of pylon, main girder and stay cable.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

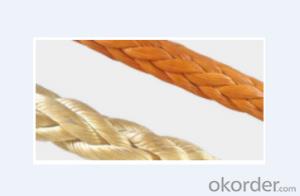

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

- Q: 20 tons sling rope, steel wire or chain?

- The strength of the steel wire rope can reach 2000-2500MPa, and is made by using cold drawn steel wire. The tensile strength is much higher than that of the chain, so that the weight of the sling can be reduced, the production efficiency can be higher, and the steel wire rope is preferred.

- Q: Which brand is better for imported rigging?

- Germany's mechanical products are better, quality world-class, CarlStahl sling rigging is Germany's old brand.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 1 phosphating coating steel wire rope (patent products), steel phosphating manganese or zinc manganese by wire surface is very wear-resisting, effectively inhibit the occurrence of fretting wear, is a substitute for plain steel wire rope upgrade, service life far beyond the structure of smooth steel wire rope, wire rope including imported from developed countries such as Germany and Japan (currently the rope is about three times of phosphating, smooth rope after may also be able to improve the phosphating film 3-60 g / M 2, wire drawing no longer after phosphating processing, direct twisting wire rope), has been in China copycat wire rope technology innovation. The innovative technology is suitable for almost all kinds of high-quality carbon steel wire rope varieties, such as elevators, steel ropes, important use steel wire rope and so on.

- Q: Notice of tower crane?

- After the tower crane is installed, the whole machine should be inspected and adjusted, and shall be ready for delivery after passing the inspection in stages and through the whole machine. In the case of no load, the deviation of the verticality between the tower and the ground shall not exceed 4/1000.. The motor and hydraulic unit of the tower crane shall be carried out in accordance with the relevant provisions concerning the motor and hydraulic device.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

Send your message to us

30Tons High Quality Manual Chain Block Chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords