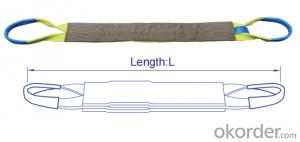

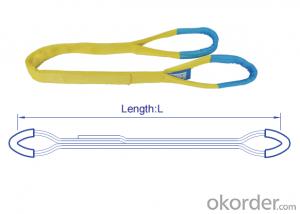

Polyester Safety Factor Flat Textle Sling Strap Webbing Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

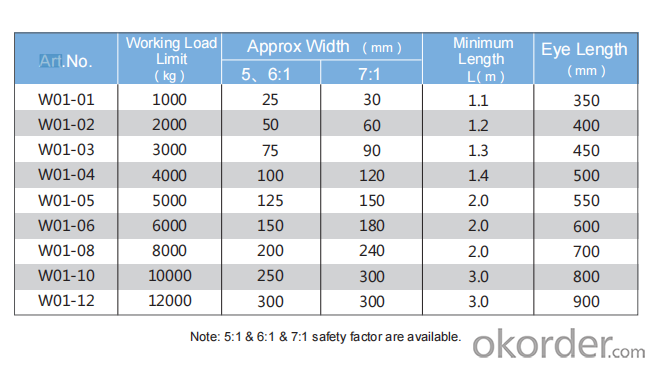

Specification

polyester safety factor flat textle sling strap webbing transportation

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

Certificate:

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Synthetic fiber tape series: flexible sling, sling, ring ring cylinder cylinder eye sling, sling, flat glass, polypropylene flat sling, sling, sling fastening belt, pickling container windproof belt, hand woven tape, tied with tape, nylon, special oil pipeline pipe sling, sling dupont. (flat suspenders can produce 1T-30T, flexible suspenders, which can produce 1T-300T)

- Q: What is the name of the wire above the train?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q: What does the inspection of rigging involve?

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, to counterfeit products in addition, patent products are generally in the rope on the outer packing is patent spraying mark, warranty book should be the main technical indicators, such as the phosphating film type and weight (film has an important influence on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q: What are the precautions for rigging in hoisting works?

- When lifting heavy objects, heavy is prohibited to stand.

- Q: The wire rope lock can hang a lot of things

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, to protect their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the type of phosphating film and film, for reference

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: Is the sling the same thing as the rigging?

- I say you should be able to understand the sling, lifting heavy rigid fetching device operation means, that is to say can directly take hanging items, mainly include: grab, clamp, suction and special sling and rigging, etc.; refers to the lifting items, tie hook combination device with flexible. In the article, usually made from high strength flexible parts (steel wire rope, lifting chain, artificial fiber tape) with end ring, hook, shackle assembly.

- Q: What are the specifications for the rigging?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. Fretting fatigue is the main cause of wire rope failure in atmospheric environment

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

- Q: Types of slings for slings

- Slings are mainly made of metal slings and synthetic fiber slings in two main categories.

Send your message to us

Polyester Safety Factor Flat Textle Sling Strap Webbing Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords