24 Inch Aluminum Coil - EN AW-5383 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

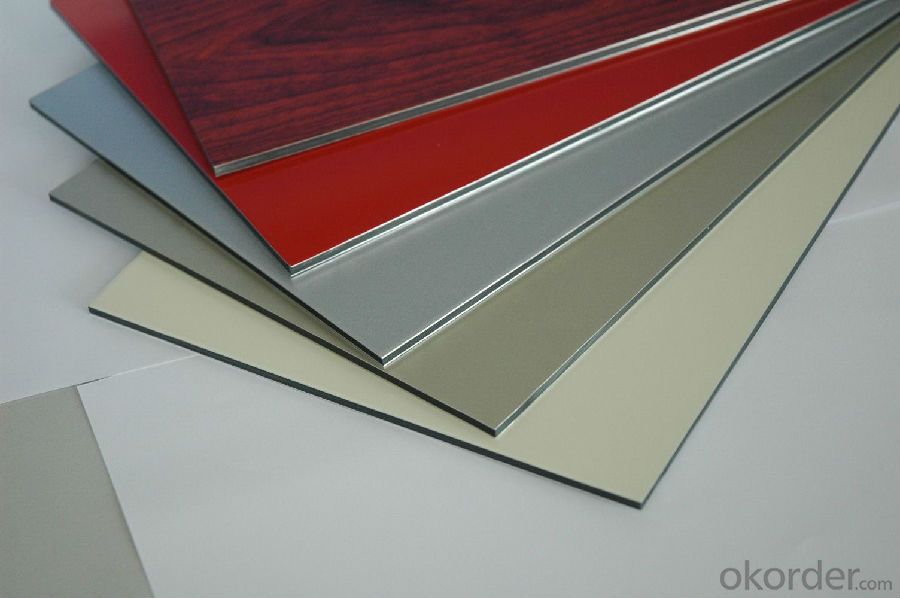

1. Structure of EN AW - 5383 PE Prepainted Aluminium Composite Panel

EN AW - 5383 PE Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5383 PE Prepainted Aluminium Composite Panel

EN AW - 5383 PE Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5383 PE Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5383 PE Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5383 PE Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

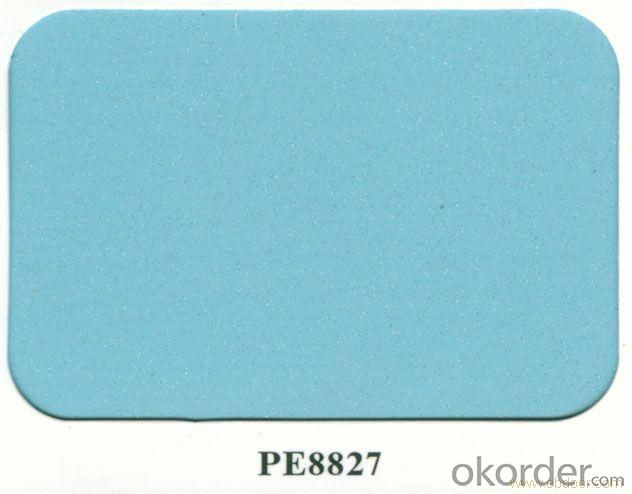

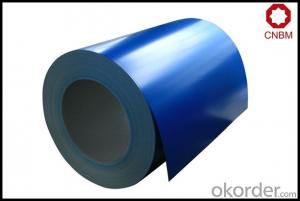

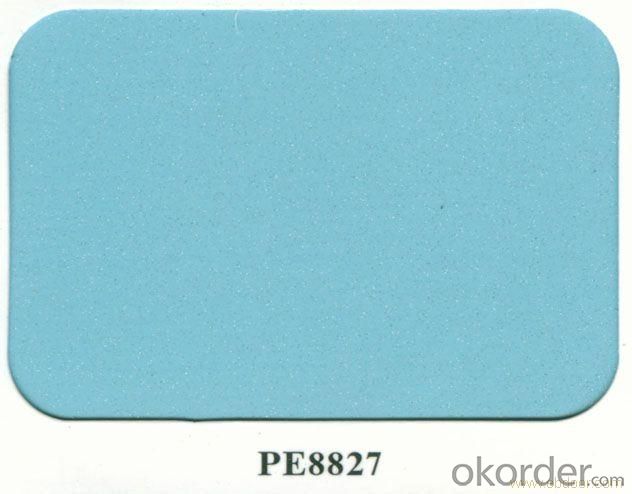

6. Image of EN AW - 5383 PE Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 5383 PE Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to use a soldering iron to fix a damaged or broken aluminum coil?

- <p>Using a soldering iron to repair an aluminum coil is not typically effective. Aluminum has a high thermal conductivity and doesn't bond well with solder, making it difficult to create a strong joint. Instead, consider using specialized aluminum welding techniques or brazing, which involves using a filler metal with a melting point higher than the base metal. For small repairs, you might also explore the use of aluminum repair epoxy or other adhesives designed for metal bonding. Always ensure to follow safety precautions and consult with a professional if the repair is complex or if the coil is part of a critical system.</p>

- Q: What are the potential applications of perforated aluminum coils?

- Perforated aluminum coils offer a wide range of potential applications due to their unique characteristics and versatility. Here are some of the potential uses of perforated aluminum coils: 1. Architectural applications: Perforated aluminum coils can be used in architectural projects for facades, sunscreens, and cladding systems. The perforations can create aesthetically pleasing designs while also providing ventilation and sun control. 2. Filtration systems: The perforated holes in aluminum coils allow them to be used as filters for various applications. They can be utilized in air, liquid, or gas filtration systems, ensuring the removal of contaminants while maintaining an efficient flow. 3. Industrial equipment: Perforated aluminum coils can be incorporated into industrial equipment such as heat exchangers, condensers, and evaporators. The perforations aid in heat transfer, promoting efficient cooling or heating processes. 4. Automotive industry: The lightweight and durable nature of perforated aluminum coils make them suitable for the automotive industry. They can be used in the manufacturing of automobile parts like grilles, radiator covers, and engine components, providing both functionality and aesthetic appeal. 5. Acoustic panels: The perforations in aluminum coils can help in sound absorption and noise reduction. They can be used in the construction of acoustic panels for auditoriums, theaters, recording studios, and other spaces where sound quality is crucial. 6. Decorative applications: Perforated aluminum coils can be utilized for decorative purposes in interior design projects. They can be shaped into screens, room dividers, or wall panels, creating visually appealing patterns and adding a touch of modernity to spaces. 7. Agricultural applications: Perforated aluminum coils can find applications in the agricultural sector. They can be used in crop protection systems, allowing for controlled air circulation while protecting plants from pests or excessive sunlight. 8. Energy-efficient solutions: The perforations in aluminum coils can be beneficial for energy-efficient applications. They can be incorporated into solar panels, allowing light to pass through while maintaining structural integrity. Overall, perforated aluminum coils offer a wide range of potential applications across various industries, including architecture, filtration, industrial equipment, automotive, acoustic panels, decorative projects, agriculture, and energy-efficient solutions. The versatility, lightweight, durability, and aesthetic appeal of these coils make them a popular choice for many different uses.

- Q: How are aluminum coils protected against oxidation?

- Aluminum coil coating is a process that safeguards aluminum coils from oxidation. It entails the application of a protective coating or layer onto the coil's surface to prevent direct contact with oxygen and other environmental factors that may induce oxidation. Acting as a barrier, this protective coating shields the aluminum from moisture, air, and other corrosive substances. Multiple types of coatings are utilized to protect aluminum coils. One common method involves applying a clear or colored organic coating, such as polyester or polyvinylidene fluoride (PVDF). These coatings not only create a barrier against oxidation but also enhance the coils' durability and aesthetic appeal. Another approach is anodizing, which immerses the aluminum coil in an electrolytic solution and passes an electric current through it. This process forms a layer of aluminum oxide on the coil's surface, serving as a natural protective barrier against oxidation. Anodized aluminum coils are renowned for their exceptional corrosion resistance and can be further improved with additional coating layers. Furthermore, chemical conversion coatings can be employed to protect aluminum coils. These coatings, such as chromate or phosphoric acid-based coatings, chemically react with the aluminum surface, generating a protective layer that prevents oxidation. In summary, safeguarding aluminum coils against oxidation is crucial for their longevity and performance. Through the application of various coatings, anodizing, or chemical conversion processes, the coils can effectively resist oxidation and maintain their integrity even in harsh environments.

- Q: Can aluminum coils be used in the production of cans?

- Indeed, the utilization of aluminum coils is applicable in the manufacturing of cans. This versatile material, known for its exceptional attributes like its lightweight nature, durability, and ability to resist corrosion, finds extensive employment in the can-making industry. Typically, during the production procedure, aluminum coils are shaped into sheets and subsequently trimmed to achieve the desired dimensions and contours of the can. These sheets are then treated with coatings, printed upon, and processed into cans using a variety of techniques. Employing aluminum coils guarantees the creation of first-rate cans that are well-suited for packaging a wide range of beverages and food items.

- Q: What are the surface treatment options for aluminum coils?

- There are several surface treatment options available for aluminum coils, depending on the specific requirements and desired outcomes. Some common options include: 1. Anodizing: This is a widely used treatment method that involves creating a protective oxide layer on the surface of the aluminum coil. Anodizing provides corrosion resistance, improves durability, and allows for color customization through dyes. 2. Painting: Aluminum coils can be coated with various types of paint to enhance their appearance, provide additional protection against corrosion, and improve resistance to UV radiation. Both liquid and powder coatings are available, with different finishes and levels of durability. 3. Coil coating: This is a continuous process where a coating material is applied to the aluminum coil's surface. The coil is then cured, resulting in a uniform and durable coating. This treatment option offers a wide range of finishes, colors, and special effects. 4. Laminating: By applying a protective film or sheet onto the surface of the aluminum coil, laminating can enhance its resistance to scratches, abrasion, and chemicals. This treatment is often used in applications where the coil may come into contact with harsh environments. 5. Brushing or polishing: These mechanical treatments can give the aluminum coil a desired texture, such as a brushed or mirror-like finish. Brushing creates a pattern of parallel lines, while polishing results in a highly reflective, smooth surface. 6. Chemical conversion coatings: These coatings are typically applied as a pre-treatment before painting or as a standalone treatment. They enhance corrosion resistance and provide a base for subsequent coatings, such as paint or powder coating. These are just a few examples of the surface treatment options available for aluminum coils. The choice of treatment will depend on factors such as the desired appearance, level of corrosion resistance, durability, and the specific application requirements.

- Q: This question asks for a brief explanation of the process involved in the manufacturing of aluminum coils.

- <p>Aluminum coil is made through a series of processes starting with the melting of aluminum ingots or scrap. The molten aluminum is then poured into a casting machine where it's cooled and solidified into large slabs. These slabs are then heated and passed through a series of rolling mills to reduce their thickness and achieve the desired coil gauge. The rolling process is often hot or cold, depending on the final application of the coil. After rolling, the aluminum is coiled into rolls and may undergo additional treatments like annealing to improve its properties. Finally, the aluminum coil is cleaned, inspected, and shipped for use in various industries such as construction, automotive, and packaging.</p>

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Yes, aluminum coils are suitable for pharmaceutical vial caps. Aluminum is a commonly used material in the pharmaceutical industry due to its excellent barrier properties, corrosion resistance, and ability to be easily sterilized. It provides a tight seal, ensuring the integrity and safety of the vial contents. Additionally, aluminum coils can be easily formed into the desired shape and size for vial caps, making them a reliable choice for pharmaceutical packaging.

- Q: Are aluminum coils suitable for solar panel applications?

- Solar panel applications can benefit from the use of aluminum coils. This lightweight and highly conductive material offers several advantages. Firstly, aluminum coils effectively transfer and dissipate heat, playing a crucial role in maintaining solar panel efficiency and lifespan. By reducing the temperature of solar cells, aluminum's excellent thermal conductivity helps prevent overheating and potential damage. Furthermore, aluminum coils exhibit high resistance to corrosion, making them an ideal choice for outdoor solar panel installations. Given the exposure to various weather conditions like rain, snow, and humidity, solar panels are prone to corrosion and degradation. However, aluminum's natural oxide layer acts as a protective barrier, ensuring corrosion prevention and enhancing the durability of solar panels. Moreover, aluminum is a cost-effective material that is readily available and easy to manufacture. Additionally, its lightweight nature simplifies the transportation and installation of solar panels, resulting in reduced overall costs. To summarize, aluminum coils are a suitable option for solar panel applications due to their exceptional thermal conductivity, resistance to corrosion, durability, and cost-effectiveness.

- Q: What benefits can utilizing aluminum coil bring to the construction industry?

- <p>Aluminum coil offers several advantages in construction, including its lightweight nature which reduces structural load and facilitates easier handling and installation. It is highly resistant to corrosion, ensuring longevity and low maintenance costs. The material is also known for its excellent thermal conductivity, making it suitable for energy-efficient applications. Additionally, aluminum coil is recyclable, contributing to sustainability and reducing environmental impact. Its versatility allows for various applications, from roofing and siding to structural components, enhancing aesthetic appeal and functionality.</p>

- Q: What is the typical conductivity of aluminum coils?

- The typical conductivity of aluminum coils is high, ranging from approximately 35 to 40 million Siemens per meter (MS/m).

Send your message to us

24 Inch Aluminum Coil - EN AW-5383 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords