Coil Aluminum EN AW-4017 PVDF Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

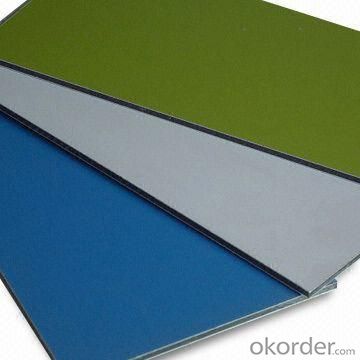

1. Structure of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

EN AW - 4017 PVDF Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

EN AW - 4017 PVDF Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

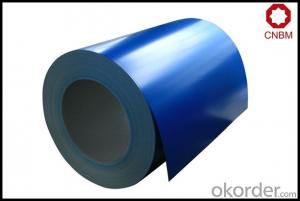

6. Image of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the necessary safety measures one should take while using aluminum coils in a kitchen setting?

- <p>When using aluminum coil in a kitchen, safety precautions include: 1) Ensuring proper ventilation to avoid inhaling fumes, as aluminum dust can be harmful. 2) Wearing protective gear such as gloves and goggles to protect your skin and eyes from potential contact with aluminum or sharp edges. 3) Handling the aluminum coil carefully to prevent cuts or injuries. 4) Avoiding contact with acidic or alkaline substances, as aluminum can react with them. 5) Not using aluminum coil near open flames or high heat sources, as it can melt or cause fires. 6) Cleaning up any aluminum dust or debris promptly to prevent slipping hazards. 7) Storing aluminum coils in a dry, cool place away from chemicals and heat sources.</p>

- Q: How are aluminum coils used in HVAC systems?

- Aluminum coils are used in HVAC systems for their efficient heat transfer capabilities. They are typically used in air conditioning units and heat pumps to cool or heat the air that circulates through the system. The coils play a crucial role in the refrigeration cycle by absorbing heat from the indoor air and releasing it outside. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for these coils, ensuring efficient and reliable performance in HVAC systems.

- Q: Are aluminum coils prone to corrosion?

- Yes, aluminum coils are prone to corrosion. Aluminum is a reactive metal that easily forms a protective oxide layer when exposed to oxygen. However, this oxide layer can be compromised by certain environmental factors, such as exposure to moisture, salt, or other corrosive substances. Over time, this can lead to the formation of corrosion on the surface of aluminum coils. Regular maintenance and proper care, such as cleaning and applying protective coatings, can help mitigate the risk of corrosion.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- I used the Easton Stealth Composite a few years back and it had the most pop of any bat I have ever used. I never seemed to miss the sweet spot, and I don't think it was necessarily because of MY skill.

- Q: Are aluminum coils suitable for automotive heat shields?

- Yes, aluminum coils are suitable for automotive heat shields. Aluminum is a lightweight and highly heat-resistant material, making it an ideal choice for heat shields in vehicles. Its excellent thermal conductivity allows it to effectively dissipate and reflect heat, protecting sensitive components and reducing the risk of overheating. Additionally, aluminum coils are durable and can withstand the harsh conditions often encountered in automotive applications.

- Q: This question asks for the method to calculate the volume of an aluminum coil given its size.

- <p>To calculate the volume of an aluminum coil, you need to know its dimensions: the length of the coil, the diameter of the wire, and the number of turns. The volume can be calculated using the formula for the volume of a cylinder, adjusted for the coil's shape. The formula is: Volume = 蟺 * (diameter/2)^2 * length * number of turns. Here, 蟺 is approximately 3.14159, diameter is the diameter of the wire in the coil, length is the total length of the coil, and the number of turns is the number of times the wire is wound around the coil. This formula gives you the total volume of the aluminum in the coil.</p>

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications due to their excellent thermal conductivity properties.

- Q: metals an aluminum can is made of, cast aluminum, 6160 aluminum, sheet aluminum

- the aluminum is alloyed with various metals to change the characteristics of the aluminum the link below shows a table showing the various chemical/metals added to aluminum to make different alloys

- Q: How do aluminum coils contribute to the insulation properties of products?

- Aluminum coils play a crucial role in enhancing the insulation properties of various products. The use of aluminum coils in insulation systems improves thermal efficiency, minimizes heat transfer, and reduces energy consumption. Firstly, aluminum is an excellent conductor of heat and electricity. This characteristic allows aluminum coils to effectively distribute and dissipate heat, preventing the transfer of thermal energy from one side of the product to another. By doing so, aluminum coils act as a barrier, minimizing heat loss or gain, which is essential for maintaining optimal temperatures in different applications. Secondly, aluminum coils have a low thermal conductivity. This means that they are not easily affected by temperature changes and do not readily transfer heat. As a result, products containing aluminum coils can better resist external temperature fluctuations, providing better insulation against hot or cold conditions. Furthermore, aluminum coils are lightweight, making them easy to handle and install in various products. This lightweight property is advantageous as it does not add significant weight to the overall structure, making it suitable for industries that require portable or lightweight insulation solutions. Moreover, aluminum is highly resistant to corrosion, making it ideal for applications in humid or corrosive environments. This durability ensures that the insulation properties of products containing aluminum coils remain effective over an extended period, without deteriorating or compromising performance. Additionally, aluminum is a recyclable material, which aligns with sustainable practices. Using aluminum coils in insulation products promotes environmental consciousness by reducing waste and energy consumption associated with manufacturing new materials. In summary, aluminum coils contribute to the insulation properties of products by efficiently distributing and dissipating heat, minimizing heat transfer, and resisting temperature fluctuations. Their lightweight nature, durability, and recyclability further enhance their effectiveness as an insulation component. Overall, aluminum coils are a valuable addition to insulation systems, improving thermal efficiency and reducing energy consumption.

- Q: Are aluminum coils suitable for thermal insulation?

- Aluminum coils, unfortunately, do not serve as suitable thermal insulation. With its high conductivity, aluminum promptly transfers heat, rendering it ineffective in impeding heat transfer between areas or maintaining desired temperatures within a given space. In order to achieve optimal thermal insulation, materials boasting low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they effectively minimize heat transfer and offer superior insulation.

Send your message to us

Coil Aluminum EN AW-4017 PVDF Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords