Clear Anodized Aluminum Coil Stock - Aluminum Foil Alloy 8011-O Temper for Waterproofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINIUM HOUSEHOLD FOIL for roofing Alloy: 8011; Temper: O Surface finishing:; one side bright, one side matte

Specifications

1. advanced processing technology

2. accurate tolerance

3. fine craft and the best quality

ALUMINIUM HOUSEHOLD FOIL FOR ROOFING

Alloy: 8011

Temper: O

Surface finishing:; one side bright, one side matte

1.Specifications

Width range | 100~940 |

Thickness range | 0.009~0.025 |

Core materials | Aluminum or steel |

Inside diameters of core | 76.0, 152.0 |

Max. outside diameter of coil for Æ76 | 560 |

Max. outside diameter of coil for Æ, 152 | 700 |

Thickness Tolerance: +/-5%

Width Tolerance: +/-1 mm

Packaging requirements: seaworthy export standard packaging.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

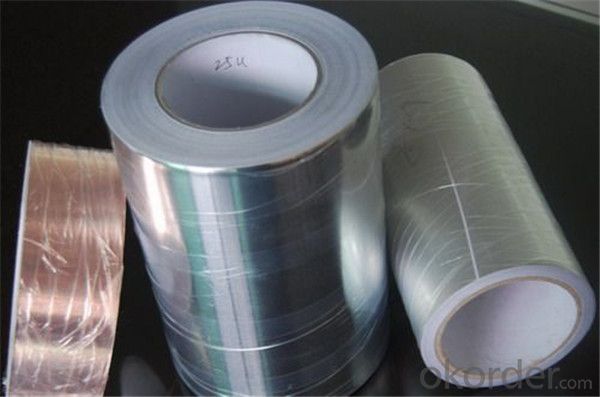

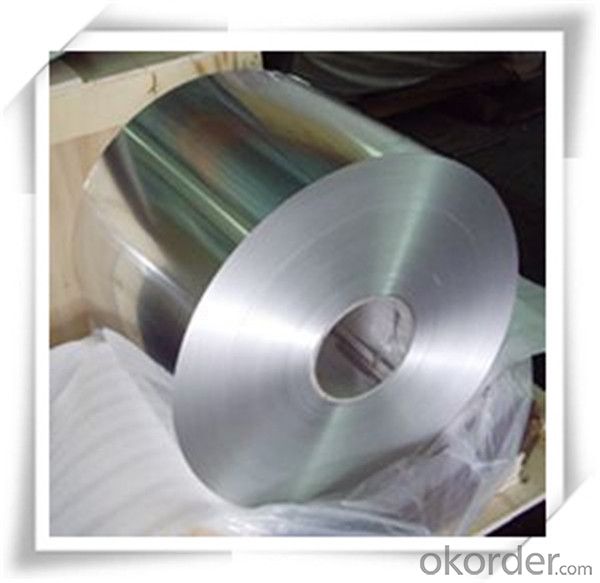

Photos

- Q: Can aluminum material be utilized as a baking surface for bread?

- <p>Aluminum coils are not typically used for baking bread. While aluminum is a good conductor of heat and is used in baking sheets and muffin tins, it's usually in a flat, solid form. Aluminum coils, often used for industrial purposes like heat exchangers, are not designed for direct food contact. For baking bread, it's best to use materials specifically designed for baking, such as silicone mats, parchment paper, or non-stick baking sheets. These materials are safe for food contact and can withstand the high temperatures required for baking bread.</p>

- Q: Explain how aluminum coils impact transportation, including considerations for logistics and safety.

- <p>Aluminum coils significantly affect transportation due to their weight and size. They are heavy and bulky, which requires specialized vehicles for transportation to ensure stability and prevent damage. The weight of aluminum coils can impact fuel efficiency and may require more powerful vehicles, increasing fuel consumption and emissions. Additionally, the transportation of aluminum coils must adhere to strict safety regulations to prevent accidents, especially when transported over long distances or on public roads. This can involve securing the load properly, using appropriate transport methods, and ensuring drivers are trained to handle heavy loads. The logistics of transporting aluminum coils can be complex, requiring careful planning and coordination to minimize delays and costs.</p>

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum is a preferred material for the manufacturing of beverage cans due to its lightweight, durability, and ability to preserve the taste and quality of the contents. Coils made of aluminum are typically used in the canning process as they can be easily shaped into a can form. The coils are rolled into sheets, which are then cut and formed into cans. Aluminum coils also have excellent heat conductivity, allowing for efficient cooling and faster production speeds. Overall, aluminum coils are an essential component in the production of beverage cans and are widely used in the industry.

- Q: This question asks for the uses or applications of aluminum coil in various industries or contexts.

- <p>Aluminum coil has a wide range of applications due to its lightweight, corrosion resistance, and high thermal conductivity. It is commonly used in construction for roofing and siding, in the automotive industry for parts and heat exchangers, and in the packaging industry for food and beverage cans. Additionally, aluminum coil is utilized in electrical applications such as transformers and electrical wiring due to its excellent conductivity. It is also employed in the manufacturing of household appliances, furniture, and various consumer goods. The coil's malleability makes it suitable for forming into various shapes and sizes, enhancing its versatility across different sectors.</p>

- Q: What is the thermal conductivity of aluminum coils?

- The thermal conductivity of aluminum coils is high, making them efficient in transferring heat.

- Q: Is it safe and appropriate to use aluminum coils for food packaging?

- <p>Yes, aluminum coils can be used for food packaging. Aluminum is a common material in the food packaging industry due to its lightweight, durability, and excellent barrier properties against light, oxygen, and moisture. It is widely used in the production of flexible packaging, such as pouches, laminates, and foils. However, it's important to ensure that the aluminum coils meet food-grade standards and are used in accordance with food safety regulations to prevent any contamination or health risks.</p>

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications. Aluminum is a corrosion-resistant material, making it an excellent choice for use in marine environments where exposure to saltwater and other corrosive elements is common. Aluminum coils are lightweight, durable, and have high strength-to-weight ratio, which is important for marine applications where weight reduction is desired. Additionally, aluminum coils can withstand extreme temperatures and have good thermal conductivity, making them suitable for various marine heating and cooling systems. Overall, aluminum coils are a popular choice in marine applications due to their corrosion resistance, durability, and lightweight properties.

- Q: Are aluminum coils suitable for construction applications?

- Indeed, construction applications can make good use of aluminum coils. Aluminum, a material known for its lightweight and durability, is extensively utilized in the construction sector. Aluminum coils find frequent application in roofing, siding, gutters, and other exterior uses owing to their resistance against corrosion and ability to withstand inclement weather conditions. Furthermore, their simple installation and maintenance procedures make them highly favored by contractors. Moreover, aluminum coils can be painted or coated to enhance their visual appeal and blend with the overall architectural design of a structure. Ultimately, aluminum coils offer a dependable and economical option for construction purposes.

- Q: What are the applications of aluminum coils?

- Due to their unique properties and versatility, aluminum coils find wide-ranging applications in various industries. The construction industry is one major field where these coils are extensively used. They are lightweight, durable, and resistant to corrosion, making them suitable for roofing, siding, and insulation purposes. Additionally, aluminum coils are commonly employed in the production of gutters, downspouts, and ventilation systems for buildings. In the automotive sector, aluminum coils are utilized for manufacturing different components like heat shields, radiators, and condensers. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and reducing the overall weight of vehicles. Moreover, aluminum coils are employed in the production of heat exchangers and air conditioning systems in automobiles. The packaging industry also heavily relies on aluminum coils. They are commonly used to manufacture beverage cans, food containers, and packaging materials. Aluminum's high ductility and excellent formability make it a preferred material for producing these products. Additionally, aluminum coils act as a barrier against moisture, light, and oxygen, ensuring the preservation and protection of the packaged contents. In the electrical and electronics industry, aluminum coils find a crucial application. They are utilized in the production of transformers, power distribution systems, and electrical conductors. The high electrical conductivity and low density of aluminum make it advantageous for these purposes. Furthermore, aluminum coils are employed in the manufacturing of appliances such as refrigerators, air conditioners, and washing machines. They are also utilized in the production of furniture, decorative items, and various consumer goods. In conclusion, aluminum coils have vast and diverse applications in industries ranging from construction and automotive to packaging, electrical, and consumer goods. The combination of lightweight, durability, corrosion resistance, and excellent formability make aluminum coils an indispensable material in numerous sectors.

Send your message to us

Clear Anodized Aluminum Coil Stock - Aluminum Foil Alloy 8011-O Temper for Waterproofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords