3000 Series Painted Aluminum Coil - EN AW-5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

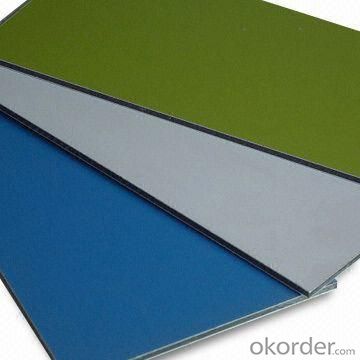

1. Structure of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5052 PE Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5052 PE Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5052 PE Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

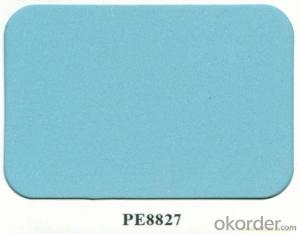

6. Image of EN AW - 5052 PE Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 5052 PE Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils play a significant role in enhancing the thermal conductivity of various products. Due to the exceptional thermal properties of aluminum, coils made from this material are highly efficient at transferring heat. The thermal conductivity of aluminum is much higher compared to other common metals, such as steel or copper. This means that when aluminum coils are used in products, they can quickly and effectively transfer heat from one area to another. For instance, in HVAC systems, aluminum coils are often utilized in air conditioning units. When the refrigerant flows through the coils, the aluminum material rapidly absorbs the heat from the surrounding air. This allows for efficient cooling, as the heat is quickly transferred away from the air and expelled, resulting in a more comfortable indoor environment. Similarly, in heat exchangers, aluminum coils facilitate the transfer of heat between two fluids or gases. The high thermal conductivity of the aluminum allows for efficient heat exchange, ensuring that the desired temperature is achieved in a timely manner. Moreover, aluminum coils are lightweight, which makes them more convenient to handle and install in various products. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics, where weight reduction is crucial. In summary, aluminum coils significantly contribute to the thermal conductivity of products by efficiently transferring heat due to their high thermal conductivity properties. Their lightweight nature further enhances their versatility and practicality in multiple industries.

- Q: How to sell the super hard 5083aluminum alloy and 5083 aluminum coil?

- Among the alloy which cannot endure heat treatment, 5083 aluminum alloy, a kind of high magnesium alloy, has the properties of intensity, machinability, anti-corrosion, electric-arc weldability and aesthetic after anodizing. The main element of 5083 alloy being magnesium, it is endowed with corrosion resistance, weldablility and moderate intensity, thus applicable to maritime areas such as ships, and cars, airplane weldments, metro light rail, and pressure vessel (such as liquid tank truck, refrigerated truck, refrigerated container), refrigerating equipment, television tower, drilling equipment, transport facility, missile parts, armor and so on.

- Q: What is the role of aluminum coils in the automotive industry?

- Aluminum coils play a crucial role in the automotive industry as they are used in the manufacturing of various vehicle components. These coils are primarily utilized in the production of heat exchangers, such as radiators and condensers, which are responsible for regulating engine temperature and air conditioning systems. Aluminum coils offer excellent heat transfer properties, lightweight construction, and corrosion resistance, making them ideal for enhancing vehicle performance and fuel efficiency. Additionally, they are also utilized in the fabrication of body panels, frames, and suspension components, contributing to the overall weight reduction of automobiles.

- Q: Can aluminum coils be used in high-magnetic field applications?

- Yes, aluminum coils can be used in high-magnetic field applications. Aluminum is a non-magnetic material, which means it does not have any magnetic properties. This makes it suitable for use in high-magnetic field applications where the presence of a magnetic field could interfere with the performance or function of the coils. Aluminum coils are commonly used in various industries, including electrical engineering, aerospace, and automotive, where high-magnetic fields are encountered. Additionally, aluminum is lightweight and has good electrical conductivity, making it an ideal choice for applications requiring efficient and lightweight coil designs.

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils vary depending on the industry and application, but common widths range from 12 inches to 60 inches.

- Q: What is the typical elongation of aluminum coils?

- The typical elongation of aluminum coils can vary depending on the specific alloy and manufacturing process, but it generally ranges from 5% to 30%.

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- It's almost always cheaper to cook at home than order out and have food delivered. Sounds like your school district is spending more money in one area of a budget to save a little money in another. Typical govt. thinking. Get them to cook your food on site so they dont have to discard food containers and you can have better food too.

- Q: Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a versatile and lightweight material that has excellent thermal conductivity properties, making it suitable for dissipating heat generated by the light source. Additionally, aluminum coils are easily moldable, allowing for the creation of intricate designs and shapes in lighting fixtures. The corrosion-resistant nature of aluminum also ensures the longevity and durability of the lighting fixture. Overall, aluminum coils are a popular choice in the manufacturing of lighting fixtures due to their numerous advantages.

- Q: What are the potential health risks associated with aluminum coils?

- The potential health risks associated with aluminum coils primarily revolve around exposure to aluminum particles, which can occur through inhalation or ingestion. Prolonged exposure to these particles may contribute to respiratory issues such as asthma and lung inflammation. Additionally, there is some concern about the potential connection between aluminum exposure and Alzheimer's disease, although more research is needed to establish a conclusive link. To mitigate these risks, it is advisable to ensure proper ventilation, minimize direct contact with aluminum surfaces, and maintain good cleaning practices to reduce the likelihood of particle release.

- Q: Explain the distinctions among various types of aluminum coils, including their properties and applications.

- <p>Aluminum coils are differentiated based on their alloy composition, thickness, temper, and surface finish. Common types include 1000 series coils, which are pure aluminum with high ductility but low strength; 3000 series, known for their formability and used in cookware; 5000 series, which are non-heat-treatable and corrosion-resistant; and 6000 series, offering a balance of strength and corrosion resistance. Thickness varies from thin gauges for flexible applications to thick gauges for structural use. Tempers range from soft (O temper) to fully hard (H temper), affecting the coil's hardness and strength. Surface finishes can be plain, coated, or embossed, impacting aesthetics and performance. Each type is chosen based on specific industry requirements like construction, automotive, or packaging.</p>

Send your message to us

3000 Series Painted Aluminum Coil - EN AW-5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords