1/8 Embossed Aluminum Alloy Sheets 5052 for Anti-Slip Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Aluminum Alloy Sheets 5052 for Anti-slip Step

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Embossed Aluminum Alloy Sheets 5052 for Anti-slip Step

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Aluminum Alloy Sheets 5052 for Anti-slip Step

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

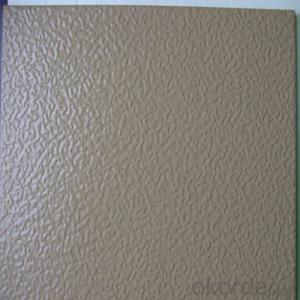

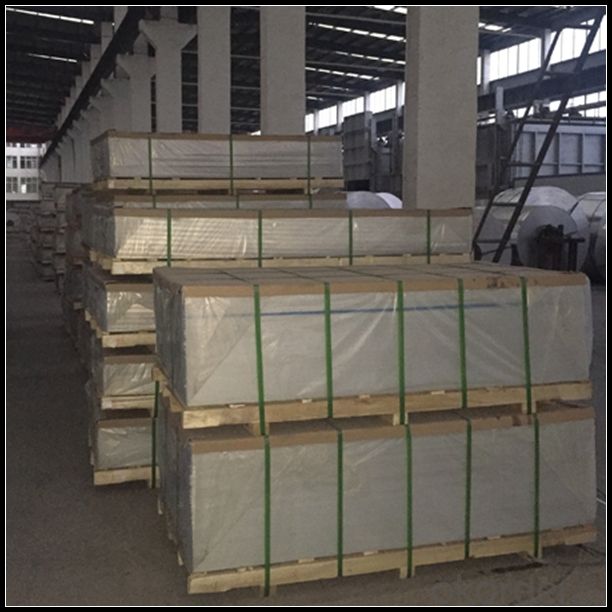

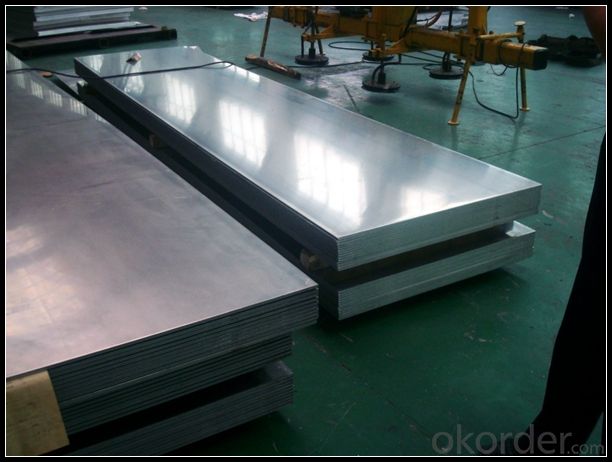

5. Image of Embossed Aluminum Alloy Sheets 5052 for Anti-slip Step

6. Package and shipping of Embossed Aluminum Alloy Sheets 5052 for Anti-slip Step

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q: Could copper wire be welded with aluminum sheet?

- Copper wire could be welded with aluminum sheet, and it needs to use low temperature welding method, if copper wire is in the unit of millimeter and aluminum sheet is also in the unit below 1 mm, you can use electric soldering iron to heat it as hybrid welding and choose low temperature welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. As for the large aluminum sheet, you can take liquefied gas multihole lance as heat source, then choose the same low temperature materials as welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. Welding fundamentals of these two welding methods: both of them are use heatable heat source to heat the matrix to 179 degree, the melting point of WEWELDING M51, then use matrix’s heat conduction to melt welding wire, completing welding. The process of melting welding wire is the process of smearing the welding wire with flux into welding area, melting welding wire completely depends on matrix’s heat conduction.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: Which kind of material does aluminum sheet(aluminum oxide) belong to?

- it's metal and belongs to hardware

- Q: Can aluminum sheet be used for food contact applications?

- Indeed, aluminum sheet is suitable for food contact applications. The food industry extensively utilizes aluminum owing to its exceptional characteristics. It is non-toxic, resistant to corrosion, and possesses a high thermal conductivity, rendering it appropriate for an array of food processing and packaging purposes. By utilizing aluminum sheets, one can craft food containers, trays, and foils, thereby offering a secure and sanitary solution for storing and transporting food. Moreover, aluminum is recyclable, making it an environmentally conscious selection for food contact applications.

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile and durable material that is commonly used in the sign-making industry. It is known for its lightweight yet sturdy properties, making it ideal for outdoor and indoor signage. Aluminum sheets are resistant to corrosion, rust, and fading, ensuring that the signage will last for a long time. Additionally, aluminum can be easily cut and shaped into various sizes and designs, allowing for creative and customized signage solutions. The material also provides a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly versatile for different signage applications. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: Are the aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant. Aluminum naturally forms a protective oxide layer when exposed to oxygen, which helps to prevent corrosion. This oxide layer acts as a barrier between the aluminum and the surrounding environment, making aluminum sheets highly resistant to corrosion. Additionally, aluminum sheets can be further treated with various coatings or anodizing processes to enhance their corrosion resistance even further. Therefore, aluminum sheets are a popular choice for applications where corrosion resistance is a critical requirement.

- Q: How do you calculate the price and weight of aluminum sheet?

- Our company imports more materials. It will be much more expensive if you are short of itAluminum prices have gone up this year

- Q: How are aluminum sheets cut or shaped?

- Depending on the desired outcome, various methods can be employed to cut or shape aluminum sheets. One commonly used technique involves the utilization of a saw, such as a circular saw or a bandsaw, equipped with a carbide-tipped blade specially designed for cutting metal. This allows for the creation of straight cuts and can be employed for both thin and thick aluminum sheets. Another approach entails the use of a shear, which is a machine equipped with sharp blades to effectively cut the aluminum sheet. Shearing is particularly advantageous when it comes to swiftly and efficiently cutting straight lines, especially for thinner sheets. For more intricate shapes or curves, aluminum sheets can be cut using either a water jet cutter or a laser cutter. Water jet cutting involves the usage of a high-pressure jet of water mixed with an abrasive substance to effectively cut through the sheet. On the other hand, laser cutting employs a focused laser beam to melt or vaporize the aluminum, resulting in precise and intricate cuts. In addition to cutting, aluminum sheets can also be shaped through processes like bending, rolling, or stamping. Bending necessitates the use of a press brake to bend the sheet into the desired angle or shape. Conversely, rolling involves employing a rolling machine to gradually shape the sheet into curves or cylinders. Lastly, stamping encompasses pressing the sheet against a die to create specific shapes or patterns. Ultimately, the choice of method for cutting or shaping aluminum sheets depends on factors such as the sheet's thickness, the desired outcome, and the availability of equipment.

Send your message to us

1/8 Embossed Aluminum Alloy Sheets 5052 for Anti-Slip Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords