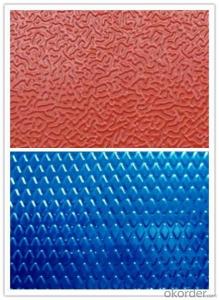

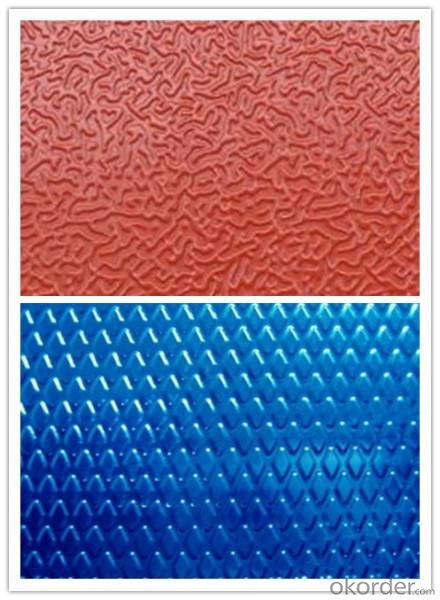

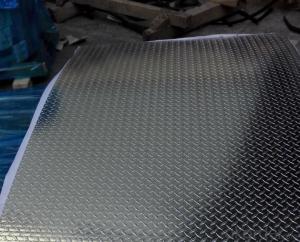

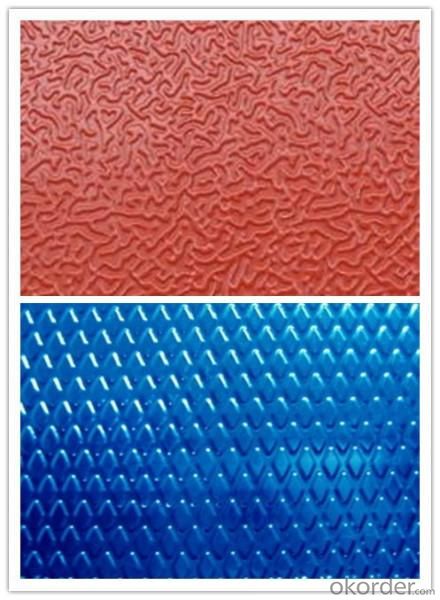

1mm Aluminum Sheets for Sale - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Embossed Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packing

Export packaging fumigation chassis, plank packing paper, coil diameter 1.1- 1.14 meters, 508 sof-core, 90 degree bending cracks. Single package weigh of coil is 1.5 -2 metic tons, coil is 3-5.7 metric tons .

1000 series aluminum coil is a commercially pure aluminum.

Excellent welding characteristics,Excellent ductile property,Excellent resistance to corrosion,Excellent conductivity.

Application of 1000 series aluminum coil,Chemical and food processing industries,Giftware material,Eye-appeal necessity needed material,Curtain wall material,Cookware material,Nameplate material,Decorative and reflective material,3000 series aluminum coil is a commercially pure aluminum with the addition of manganese. Good corrosion resistance,Excellent weldability,formability,Good corrosion resistance,Moderate strength,Specially, 3104 aluminum alloy is a typical deep-drawing material.

Application of 3000 series aluminum coil,Cooking and kitchen equipment,Decorative trim,Food & Chemical processing and storage container,Tank container,Pressure vessel,Cooling fin,Deep drawing processing material. 5000 series Aluminum coil is a typical Al-Mg aluminum product. High stength, Good salt water resistance, Good low temperature ressistance.

We have advanced equipment in the factory. Neat factory mill, advanced machines and skilled workers enable to manufacture high quality products.

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- warm and cool whevs u want bro

- Q: Can aluminum sheets be easily bent or shaped?

- Due to its malleability, aluminum sheets are easily bendable and shapeable. This soft and lightweight metal possesses remarkable formability characteristics, making it highly suitable for various shaping processes. Numerous techniques, including press braking, roll forming, and stretch forming, can be used to easily bend, fold, or form aluminum into different shapes. Its malleability allows for the creation of intricate shapes without any cracking or breaking. Moreover, the low melting point of aluminum enables further shaping through processes like hot bending or thermoforming. As a result, aluminum sheets offer exceptional flexibility and ease of shaping, making them a favored choice in industries such as automotive, aerospace, construction, and manufacturing.

- Q: Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- It really depends on your formula and how the aluminum is being used in the formula. Is it a part of the fuel or is an additive to the fuel for sparks?

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- The allowable deviation of plate thickness in GB/T3880.3-2006 "general industrial aluminum plate, strip and Aluminum Alloy third part:" size deviation provisions, I have the standard download URL sent to you a message, please check.The deviation is divided into ordinary and high level, +0.10, -0.12

- Q: What are the distinctions between standard and custom-made aluminum sheets?

- <p>Standard aluminum sheets are mass-produced with fixed dimensions and specifications, making them readily available and cost-effective. They are suitable for common applications where specific dimensions are not a priority. Custom-made aluminum sheets, on the other hand, are tailored to meet specific requirements regarding size, thickness, and other properties. They offer flexibility for unique applications but may be more expensive and have longer lead times due to the specialized manufacturing process.</p>

- Q: How do aluminum sheets perform in terms of creep resistance?

- The excellent creep resistance of aluminum sheets is well-known. Creep refers to the gradual deformation of a material under a constant load over time. In comparison to steel and other metals, aluminum exhibits a relatively low creep rate. This means that it deforms at a slower pace when subjected to the same load and temperature conditions. As a result, aluminum sheets are ideal for applications that require dimensional stability and resistance to long-term deformation. Furthermore, aluminum's low susceptibility to creep enables it to endure high temperatures without undergoing significant deformation. Consequently, it finds suitability in a wide range of industries, including aerospace, automotive, and construction. Nevertheless, it is crucial to consider that the creep resistance of aluminum sheets can vary depending on factors such as the alloy employed, heat treatment, and other variables. Hence, it is vital to select the appropriate aluminum alloy and design that can optimize creep resistance for specific applications.

Send your message to us

1mm Aluminum Sheets for Sale - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Embossed Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords