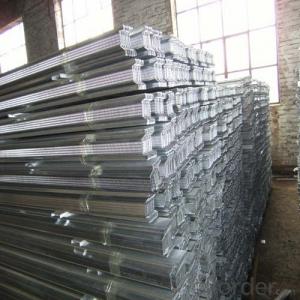

Ceiling Profile for Inner Roofing

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20FCL m

- Supply Capability:

- 2X20FCL Per Day m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

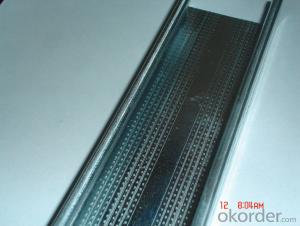

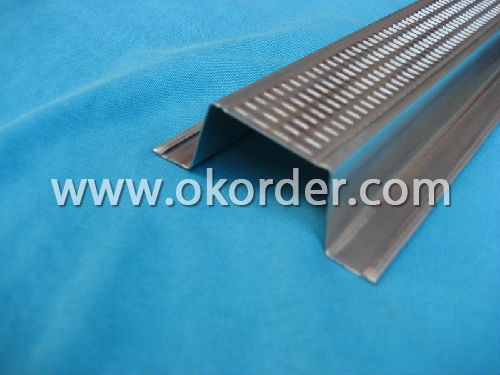

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q: What is the light steel keel?

- Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel. (1) product specifications series of keel main specifications are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60. (2) Product marking method The marking order of light steel keel is: product name, code, width of section shape, height, thickness of steel plate and standard number. Such as cross-sectional shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1. Smm of the ceiling keel marked as: building light steel keel DC 5 0 XIS XI. SGBllg sl (3) the appearance of quality light steel keel shape to be smooth, angular, cut not allowed to affect the use of burrs and deformation. Galvanized layer is not allowed to have skin, from the tumor, shedding and other defects. For corrosion, damage, dark spots, pitting and other defects, according to the provisions of the method should be tested in accordance with the provisions of Table 2-81. Appearance quality inspection, should be 0.5m away from the product under the conditions of bright light, the visual inspection. Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent products not less than 120g / m * m, first-class goods is not less than 100g / m * m, qualified products not less than 80g / m * m. Paint keel with cold-rolled continuous hot-dip galvanized steel strip and paint belt as raw material, through the cold bending process, composite rolling from a reasonable "T" -shaped structure of the thin-walled profile.

- Q: Light steel keel and wood keel ceiling unit area of the amount of material how to calculate?

- Light steel keel and wood keel ceiling unit area of the amount of material, the budget staff can help you calculate, according to the area of the amount of fixed unit material, you can calculate the unit area of light steel keel and wood keel ceiling material consumption.

- Q: What is the ceiling keel, what role

- According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q: Light steel keel second ceiling

- Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q: Light steel keel ceiling need to pay attention to what issues?

- Light steel keel ceiling works in the construction of the need to pay attention to the following main aspects: ????1, ceiling elevation, size, from the arch and shape should meet the design requirements. ????2, the finishes of the material, variety, specifications, patterns and colors should meet the design requirements. ????3, dark keel ceiling works of the boom, keel and finishes the material must be installed firmly. ????4, boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be treated by surface corrosion; wood boom, keel should be anti-corrosion, fire treatment. ????5, gypsum board seams should be based on their construction technology standards slab crack treatment. Installation of double gypsum board, the surface plate and the base plate of the joints should be staggered, and not in the same keel on the seam. ????6, the surface material should be clean surface, consistent color, no warping, cracks and defects. The bars should be straight and wide ????Cause ????7, decorative panels on the lamps, smoke detectors, sprinklers, tuitas and other equipment, such as the location should be reasonable, beautiful, and the decorative panels should be consistent, close. ????8, metal boom, keel joints should be uniform, corners should be anastomosis, the surface should be flat, no warping, hammer India. Wooden boom, keel should be straight, no split, deformation. ????9, ceiling filled with sound-absorbing material varieties and laying thickness should meet the design requirements, and should be anti-scattered measures. ????Details can be found in "GB50210-2001 building decoration works construction quality acceptance norms" in Section 6.2 "dark keel ceiling project" and Section 6.3 "Ming kei ceiling project" in the relevant provisions.

- Q: Do steel keel ceiling, need to use white latex?

- I feel enough Latex is all right. Woodworkers lack this. Also downstairs to say right. Woodworking is responsible for the ceiling, the gap putty is the work of oil workers.

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated are aluminum alloy material, a special keel is relatively flat, light source Yuba exhaust fan are tailor-made tailor-made sensory is very beautiful but also durable but the spread is also a great traditional buckle ceiling (the main material + artificial Fee) generally in the 60 ~ ~ 120 or so with the integration may be more than 200

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling of the keel spacing is too small to easily affect the ceiling of the sound effects and life. Keel skeleton is commonly used in the ceiling of the material, if the early construction of non-standard will seriously affect the aesthetic effect, and may even affect the safety of occupants. The spacing of the keel in the ceiling is very important. The spacing of the keel is different for different ceiling materials.

- Q: Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

1. Manufacturer Overview

| Location | Bazhou, China |

| Year Established | 1994 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | China; Russia; the US; France; Germany; Japan; South Korea; the Middle East; Southeast Asia; Australia; South Africa and many other countries and regions |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 12000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Ceiling Profile for Inner Roofing

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20FCL m

- Supply Capability:

- 2X20FCL Per Day m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords