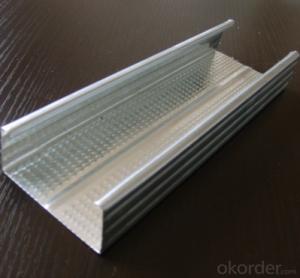

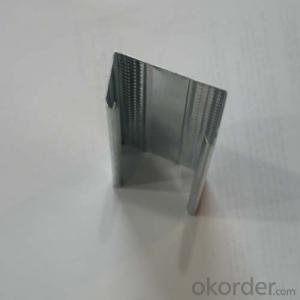

Drywall Galvanized Structural Sheet Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Product Overviews

Advantage and feature:

1.Light, good strength, cauterization resistance and water resistance

2.Matching magnesium fire-proof board, gypsum board and many other walll and ceiling board

3.Moisture-proof, shock-resistance, environment-friendly and so on.

4.Easy and fast for install, time-saving

5.High quality, competitive price and complete sets of style

6.We can supply you the products based on your specific requirements

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel wall to withstand the number of wind load

- This test really no standard, the general wall is not the index of wind pressure, mechanics is also the most test is the impact and static load test, personal feeling according to the thickness of the keel, the height of the wall, supporting the keel, supporting card Whether it is complete, wall pressure against the wind is almost 200 ~ 600Pa no obvious deformation.

- Q: Light steel keel wall waterproof

- Used to resist external UV radiation, natural aging and chemical corrosion, effectively extend the coating use

- Q: Home improvement in the partition

- Lightweight brick wall; a brick made of foam cement material, can replace part of the brick wall, reduce the building load, but the high water absorption. Its structure, sound insulation with the red brick wall is almost the same for the indoor simple wall;

- Q: Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- You said the mineral wool board and gypsum board can not be used because they are not waterproof tide will be deformed Recommended ceiling with PPC or aluminum gusset plate is to do with the wall with calcium silicate board is the cement board on the line waterproof paint with a little better is no problem

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- Keel fixation requires the use of expansion bolts fixed, but now many practices are directly linked with steel nails, so more convenient, the effect is almost, of course, is not good with expansion bolts. Top and bottom with 75 days keel. Then there are 75 vertical keels.

- Q: Light steel keel wall Why do not cross brace welding with welding

- The bracelet can be fixed with a support card, card holder and connector, and can be fixed with a riveted sleeve if necessary, but not welded by welding.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- 1, the main structure is completed, before the ceiling, the first wall construction. 2, light steel keel installation is completed, should be based on the construction acceptance of the keel for acceptance, such as skeleton does not meet the requirements, should be promptly adjusted. 3, the installation of gypsum board must be stress-free installation, first with self-tapping nail fixed gypsum board center parts, and then fixed the edge, so that the gypsum board after installation without any stress.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition can be said that the construction industry is now the forefront of science and technology, originated in Japan, because Japan is earthquake-prone countries, the seismic performance of the wall is very particular about, and high prices in Japan, Too high, so the house designers have invented the light steel keel inorganic composite board partition. Light steel keel inorganic composite board wall composed of light steel keel and double-sided inorganic composite panels, up and down wrapped sound insulation pad, with a solid and reliable, practical and practical features, and the thickness of only about 175px, 300px than the average wall thin. One inorganic composite board for the new inorganic composite materials, environmentally friendly materials, non-toxic and tasteless, excellent physical properties. It is composed of silicon, calcium and magnesium composite cementitious materials, and is applied by polymer composite technology. With fire-retardant, heat insulation, waterproof, waterproof, pest control, mildew, light, high strength, environmental protection and energy saving, construction fast, easy to finishes and so on. Light steel keel and inorganic composite board composed of light steel keel inorganic composite board partition wall as a partition, with strong earthquake resistance, sound insulation, easy to dismantle modification and space saving and other characteristics, a market will be favorable by the Japanese market , Has been widely used in foreign countries.

- Q: Light steel keel partitions and finished partitions

- Light steel: the frame and the outer panel should be in the construction site processing, but also brush at least 2 times the putty +2 paint. Finished partition: mainly in the factory processing, in the field just assembled only.

Send your message to us

Drywall Galvanized Structural Sheet Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords