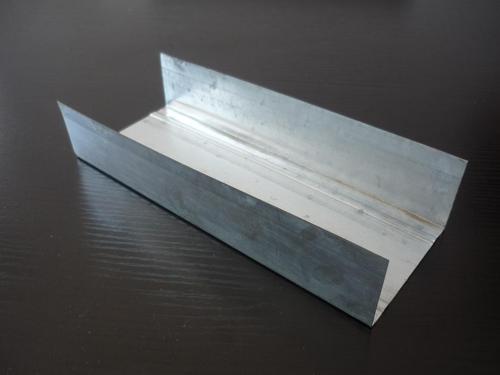

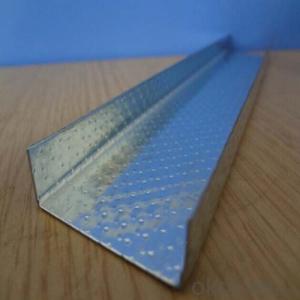

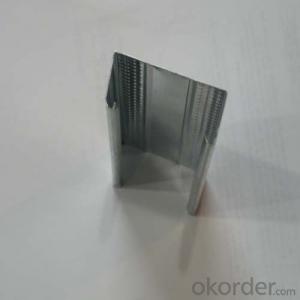

Drywall Steel Frame

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture-proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- The interior walls can be made of light steel keel partitions, but the bathroom walls should be made of brick walls. The bathroom is generally water, wall with gypsum board, then the gypsum board will be bad water. So apply brick walls, and then paste the tiles on top.

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Light steel keel gypsum board system is usually double-sided wall structure, that is, "plate - keel (cavity) - plate" structure, each side of the wall board for the single or double gypsum board, Light steel keel. In order to obtain better sound insulation effect, in the cavity filled with rock wool board or glass wool.

- Q: Light steel keel wall to withstand the number of wind load

- According to the thickness of the keel, the height of the partition, supporting the keel, supporting the card is complete, the wall is also about 200 ~ 600Pa wind pressure is not obvious deformation.

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- With the filling block wall, and the same brick with the nail what is no problem, the weight is not heavy, the thinnest filling block is 120 thick, even the total thickness of double-sided plaster does not exceed 180, or light The partition wall is also the line, faster, but also durable, more than gypsum board wall to spend more, but at least the first nibbling nails are no problem, more durable and reliable, the weight is also light, the normal stay on the trip.

- Q: Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q: Home improvement in the partition

- Glass partition is divided into two kinds of flat glass and glass tiles: This is a kind of beautiful wall, good lighting performance of the wall;

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- But in a dry place, with a 20 years no problem, light steel keel life and its wall thickness, sealing plate varieties and thickness are closely related. Do not worry about the damp environment, it is recommended to use light steel keel partition, after all, it has light, space-saving, construction convenience, the cost is relatively low advantage.

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- As for the sound insulation performance, and not because of the wall is light and affected, but higher than the national noise standards, light steel keel of the outer package with noise pad, can play a very good sound insulation, and the same thickness of the concrete slab The sound insulation of the partition is only 32 decibels. According to the authority test, light steel keel inorganic composite board partition can block the noise reduction of about 38 dB, significantly higher than the international standard of 30 dB, more to ensure the comfortable living needs of living.

- Q: Light steel keel partitions and finished partitions

- Light steel: the frame and the outer panel should be in the construction site processing, but also brush at least 2 times the putty +2 paint. Finished partition: mainly in the factory processing, in the field just assembled only.

Send your message to us

Drywall Steel Frame

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords