Building Material Galvanized Profile for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Material Galvanized Profile for Drywall

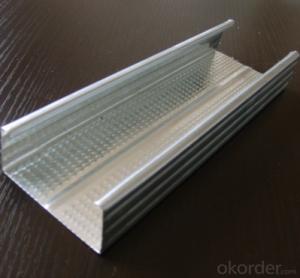

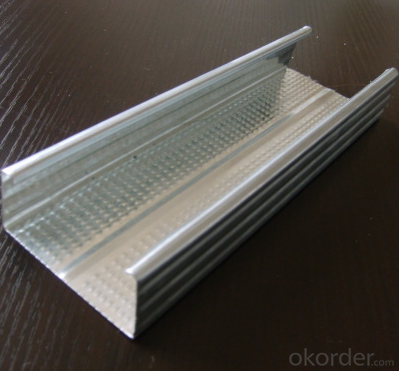

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Detail description

1.Materials:galvanized steel strip

2.Thickness:0.4-1.2mm, size:90*40, 90*50

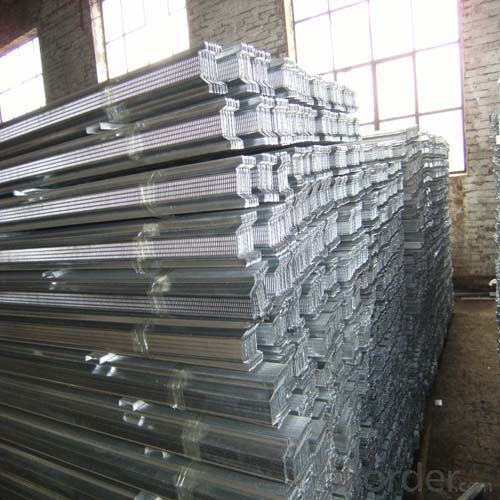

3.Length:2.8m,3.0m,3.2m or according to order

4.OEM steel keel service can be avaliable

5.Package: bundle package with plastic strip

6.Application; drywall partition

Specification

Drywall 35*22*12*68, thickness 0.45mm - 1.0mm,length 2.8mm,2.9mm,3mm

Drywall

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Function and advantage

1.good quality, hot dip galvanized steel coil

2.light weight , easy install

3.surface: zinc coat, full with dot, high strength

4.strong bearing capacity, ametabolic

5.the production ability strong, 21 production lines-3200 tons per month

6.meet the GB standard

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- Home improvement living room ceiling works, gypsum board force does not need to add nine per cent board. Recommendation: direct use of light steel keel or wood keel and then add gypsum board just fine. Tip: If the shape is complex, available blockboard to take advantage of the keel on it

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- With the development of social market economy, the market spread of various industries. Decoration materials are the same, the current market in the circulation of many brands. In fact, each brand has its corresponding value advantage. In accordance with the brand value and the overall quality is concerned, decorative ceilings currently Jieke Knaufort is the same high-end international brands, Long card is the domestic first-line brand, the real Taishan can, but Taishan many fried in the market. Other domestic small brands countless. And ultimately to see their specific positioning.

- Q: Can my light steel keel ceiling withstand the weight?

- According to your argument is no problem. Please feel free to use it

- Q: Home improvement in the partition

- Light steel keel, wood keel wall: light steel keel is a substitute for wood keel products, fire effect is significant (when using wood keel to brush fire retardant coating). As a partition wall of the external use of the plate there are gypsum board, Ed panels and aluminum-plastic panels, according to the actual requirements. If you want to do noise effects, in the middle of the installation of rock wool or mineral wool sound-absorbing panels;

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q: What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In fact, the soft bag is not soft package, sponge package in a 9mm Austrian Song board, this is the soft bag, and then in order to fixed on the wall, in the light steel keel wall to do a lining you said, That is, I mentioned above the blockboard base.

- Q: Light steel keel wall cheap or cheap red brick

- Of course, is the light steel keel, probably in 70 a square, wall, then 12 of the wall art manual brick is 80, double-sided batch of 30, is 110!

- Q: With light steel keel gypsum board do partition wall price how to count?

- Double-sided labor costs more than 20 yuan per square meter, the material to see the grade of gypsum board and the thickness of the keel. Generally not more than 20 yuan per level. Plus freight and handling costs, loss. Offer 60 yuan per flat can be.

Send your message to us

Building Material Galvanized Profile for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords