Diamond Tread Aluminum Sheets for Sale - Low Price Aluminium Slab with Better Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,7075,6063,8011, etc.

The temper is include H14, H22, F,O, H44,H112,F,O, H114,etc.

2. Main features of the product

a. the best-discount cheapest price

b. Frist-Class Service.

c. Shortest service.

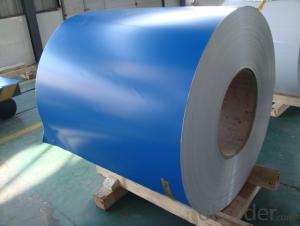

3. Image.

4. Product detailed sizes:

2000mm*2000mm,1000*1000MM, 1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, big 5 bar, and small 5 bar and else grades,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: Using thin copper sheets and thin aluminum sheets, respectively, from heat source heat conduction to aluminum heat sink, which kind of efficiency is higher?

- Aluminum cooling fast! Copper conducts heat quickly! Is it clear enough?.Copper has a good heat conductivity. For metal conductive ability of thermal conductivity is strong.

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets exhibit a relatively high coefficient of thermal expansion, causing them to expand significantly under heat and contract when cooled. This behavior stems from aluminum's nature as a metal with a relatively low melting point and excellent heat conductivity. Heating aluminum sheets increases the energy of its metal atoms, causing them to vibrate and move more rapidly, resulting in expansion. Conversely, cooling the sheets reduces their energy, causing the metal atoms to slow down and move closer together, leading to contraction. Therefore, it is crucial to consider the thermal expansion properties of aluminum sheets when using them in applications that involve temperature fluctuations, as this can impact the material's overall dimensions and performance.

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: What are the different methods for finishing the edges of aluminum sheets?

- There are several methods for finishing the edges of aluminum sheets, depending on the desired outcome and application. One common method is edge trimming, which involves removing excess material from the edges of the sheet to achieve a smooth and straight edge. This can be done using various tools such as shears, saws, or routers. Another technique is edge deburring, which is used to remove any sharp or rough edges left after cutting. This is often done using sanding or grinding tools to smooth out the edges and create a more polished finish. Additionally, edge rolling is a method used to create rolled or rounded edges on aluminum sheets. This can be achieved through a rolling machine that applies pressure to the edges, bending them to the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to create custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that can enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option to consider. This process involves applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps to protect the edges from corrosion or other damage. Overall, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific requirements of the project.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels.

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: i keep hearing all these things about burning aluminum foil and such

- Yes, aluminum is a soft metal andit will not hold up well in a fire and if it's a hot fire you don't want to breathe in any fumes the rim might give off. If you want to use a rim, best to use steel. Or like the other guy said, rocks or bricks.

Send your message to us

Diamond Tread Aluminum Sheets for Sale - Low Price Aluminium Slab with Better Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords