Delemar Aluminium Profile Construction and Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

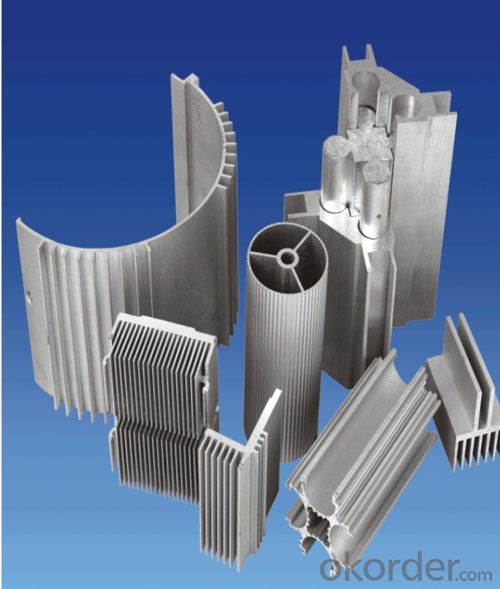

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

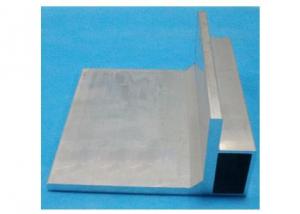

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different surface engraving options for aluminum profiles?

- Aluminum profiles have several options available for surface engraving. Some of the most common techniques include: 1. Laser engraving: Achieving precise and clean results, laser engraving uses a high-powered laser to etch intricate patterns and fine details onto the aluminum profile. 2. Diamond drag engraving: Also known as diamond scratch engraving, this method scratches shallow grooves onto the surface of the aluminum profile using a diamond-tipped tool. It is suitable for creating logos, serial numbers, or simple designs. 3. Chemical etching: Custom designs, patterns, or textures can be created on the aluminum profile by using a chemical solution to selectively remove specific areas. 4. Mechanical engraving: A rotating cutting tool is used to engrave the aluminum profile in this method. It is commonly used for basic text or simple designs and can be performed manually or with the assistance of a CNC machine. 5. Sandblasting: By shooting a high-pressure stream of sand or other abrasive materials onto the surface of the aluminum profile, sandblasting creates a textured surface and achieves a matte or frosted finish. Each of these engraving options offers unique benefits and should be chosen based on the desired outcome, complexity of the design, and budget considerations. When selecting the most suitable engraving method for aluminum profiles, it is important to consider factors such as durability, precision, and aesthetic appeal.

- Q: Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- The biggest weakness of powder spraying is that it is afraid of the ultraviolet radiation of the sun. The long-term radiation will cause the natural fading. The face of the aluminum plate and the non bright face are obviously different in color after a few years, and the color difference is obvious for 2-5 years. Now appearing on the market name of color for aluminum, aluminum doors and windows, is to use ordinary aluminum powder coating and. Aluminum doors and windows to increase color varieties, but also to enhance corrosion resistance. Another kind of electrostatic spraying liquid spraying, also called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries. In the past two years, it has been widely used in aluminum curtain wall. Because of its excellent characteristics, more and more attention has been paid to the construction industry and users. Fluorocarbon coating has excellent anti fade, anti frost, anti air pollution (acid rain) corrosion, anti UV ability, strong crack resistance and can withstand harsh weather conditions. Is less than general paint

- Q: What is the composition of aluminum profiles?

- Aluminum profiles are typically composed of aluminum alloy, which is a combination of aluminum and other elements. The specific composition of aluminum profiles can vary depending on the intended use and desired characteristics. Common alloying elements include copper, magnesium, silicon, and zinc. These elements are added to enhance the strength, durability, and corrosion resistance of the aluminum profiles. Additionally, trace amounts of other elements may be present to further refine the properties of the profiles. Overall, the composition of aluminum profiles is carefully engineered to ensure optimal performance and versatility in various applications.

- Q: Are aluminum profiles suitable for noise barriers?

- Yes, aluminum profiles are suitable for noise barriers. Aluminum is a lightweight and durable material that can effectively reduce noise transmission. It is often used in the construction of noise barriers due to its ability to absorb and reflect sound waves, helping to minimize noise pollution in various environments. Additionally, aluminum profiles can be easily customized and installed, making them a practical choice for noise barrier applications.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Aluminum profiles prove to be a suitable option for utilization within chemical processing environments. This versatile and corrosion-resistant material possesses the ability to endure exposure to a vast array of chemicals. Its exceptional resistance extends to numerous common chemicals, encompassing acids, bases, and solvents. Furthermore, aluminum profiles can acquire additional protection through the application of specialized coatings or finishes, like anodizing, which heightens their resistance against chemical corrosion. Moreover, within chemical processing environments, aluminum profiles present other advantages, such as their lightweight composition, high strength-to-weight ratio, and simple fabrication techniques. These qualities render aluminum profiles a favored choice for various applications in chemical processing industries, including the construction of tanks, piping systems, and process equipment.

- Q: This question asks for the standard specifications and measurements of aluminum profiles that are frequently utilized in construction projects.

- <p>Aluminum profiles used in construction come in various specifications and measurements. Commonly, they are categorized by series such as 6060, 6061, 6063, and 6082, each with different mechanical properties. Sizes can range from small profiles like 20x20mm to large ones like 200x200mm or more. Thicknesses typically vary from 1mm to 6mm, depending on the structural requirements. Lengths can be customized but are generally available in standard lengths such as 6 meters. The profiles are measured in terms of their width, height, and thickness, and they are designed to meet specific load-bearing and aesthetic needs in construction. It's important to consult with suppliers or construction specifications for the exact measurements required for a particular project.</p>

- Q: How are aluminum profiles insulated?

- Aluminum profiles are typically insulated using a thermal break system. This involves placing a non-conductive material, such as polyamide or polyurethane, between the inner and outer sections of the aluminum frame. This insulation helps to reduce heat transfer and improve energy efficiency in buildings.

- Q: What are the different types of gaskets used with aluminum profiles?

- There are several different types of gaskets that are commonly used with aluminum profiles. 1. EPDM (Ethylene Propylene Diene Monomer) Gaskets: These gaskets are made of a synthetic rubber material that is highly resistant to weathering, UV radiation, and ozone exposure. EPDM gaskets are commonly used in outdoor applications where they need to provide a tight seal and withstand harsh environmental conditions. 2. Silicone Gaskets: Silicone gaskets are known for their excellent temperature resistance, making them a popular choice for applications that involve extreme heat or cold. They also have good resistance to chemicals and UV radiation, making them suitable for a wide range of industrial and commercial applications. 3. PVC (Polyvinyl Chloride) Gaskets: PVC gaskets are made of a plastic material that is widely used for its excellent resistance to chemicals, oil, and moisture. They are commonly used in applications where a tight seal is required, such as in doors, windows, and other architectural applications. 4. Neoprene Gaskets: Neoprene gaskets are made of a synthetic rubber material that offers good resistance to oils, chemicals, and weathering. They are commonly used in applications that require both sealing and vibration dampening, such as in machinery and equipment. 5. Nitrile Gaskets: Nitrile gaskets, also known as Buna-N gaskets, are made of a synthetic rubber material that offers excellent resistance to oils, fuels, and solvents. They are commonly used in automotive and industrial applications where resistance to oil and fuel is crucial. These are just a few examples of the different types of gaskets that can be used with aluminum profiles. The choice of gasket will depend on the specific requirements of the application, including the desired level of sealing, environmental conditions, and chemical compatibility.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors that are commonly used with aluminum profiles. These connectors are designed to join two or more aluminum profiles together at a corner, allowing for the creation of various structures such as frames, enclosures, and shelving units. One common type of corner connector is the 90-degree angle bracket. This type of connector features a right angle shape, with holes on each side to accommodate screws or bolts for fastening the profiles together. The 90-degree angle bracket is versatile and can be used for a wide range of applications. Another type of corner connector is the 45-degree angle bracket. This connector is similar to the 90-degree angle bracket but is designed to create a 45-degree angle joint between two profiles. It is commonly used in applications where a slanted or angled structure is desired. T-slot corner connectors are another popular choice. These connectors feature a T-shaped slot that allows for easy insertion of the profiles. They are typically used in applications where adjustability and flexibility are important, as they allow for easy repositioning and modification of the structure. Some corner connectors are designed specifically for certain types of profiles, such as the end cap connector. This type of connector is used to cap off the end of a profile, providing a finished look and protecting the profile from damage. In addition to these, there are various other corner connectors available, such as corner gussets, angle plates, and corner brackets. Each type of connector has its own unique features and advantages, making them suitable for different applications and requirements. Overall, the different types of corner connectors used with aluminum profiles provide a wide range of options for joining and assembling structures. These connectors offer strength, stability, and versatility, making them essential components in the construction of various aluminum profile-based projects.

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

Send your message to us

Delemar Aluminium Profile Construction and Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords