Rona Geotextile Deer Guard Fence - Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

2. Deer fence introduction:

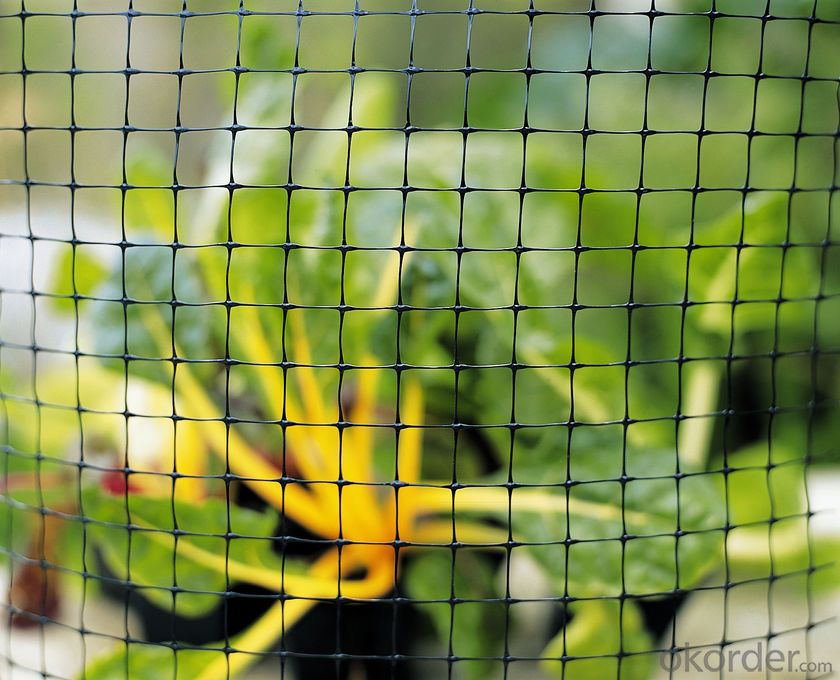

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the applications of geotextiles in coastal engineering?

- Geotextiles have several applications in coastal engineering, including shoreline protection, erosion control, and sediment filtration. They are used to stabilize and reinforce coastal structures such as revetments, breakwaters, and seawalls. Geotextiles also help in preventing soil erosion by acting as a barrier between the beach or dune and the water, reducing the impact of wave action. Additionally, they can be used to filter sediment and prevent the clogging of drainage systems in coastal areas. Overall, geotextiles play a crucial role in maintaining and safeguarding coastal environments.

- Q: How do geotextiles affect soil properties?

- Geotextiles can have various effects on soil properties. They can enhance soil stability and prevent erosion by acting as a barrier against soil movement and water flow. Geotextiles can also improve soil filtration and drainage by allowing water to pass through while retaining soil particles. Additionally, they can provide reinforcement to the soil, increasing its load-bearing capacity and reducing settlement. Overall, geotextiles can significantly influence soil properties, improving its performance and durability in various geotechnical applications.

- Q: Can geotextiles be used in mining and landfill closure applications?

- Yes, geotextiles can be used in mining and landfill closure applications. Geotextiles are often used in these applications to provide soil stabilization, erosion control, and drainage solutions. They can help in preventing soil erosion, promoting vegetation growth, and improving overall environmental sustainability in these areas.

- Q: Geotextile special staple fiber where needed

- How much is a ton?

- Q: How do geotextiles interact with other geosynthetic materials?

- Geotextiles interact with other geosynthetic materials by providing reinforcement, filtration, separation, and drainage functions. They can be used in combination with geogrids, geomembranes, geocells, and other geosynthetics to enhance the overall performance and effectiveness of geotechnical engineering projects.

- Q: Do you have a geotextile bed?

- Well, geotextile material is not environmentally friendly

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles can be considered environmentally friendly. Geotextiles are designed to have minimal impact on the environment and can be made from recycled materials. They can help with erosion control, soil stabilization, and filtration, reducing the need for harmful chemicals or excessive soil excavation. Additionally, geotextiles are often biodegradable or can be recycled at the end of their lifespan, further contributing to their environmental friendliness.

- Q: Geotextile with glue can stick cement wall

- With the wind oil fine soaked, wipe with a rag off.

- Q: Can geotextiles be used for filtration purposes?

- Yes, geotextiles can be used for filtration purposes. They are permeable fabrics that can effectively filter out fine particles while allowing water or other fluids to pass through. This makes them suitable for applications such as erosion control, drainage systems, and preventing soil contamination.

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

Send your message to us

Rona Geotextile Deer Guard Fence - Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords