Geotextile Brico Depot Deer Guard / Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

2. Deer fence introduction:

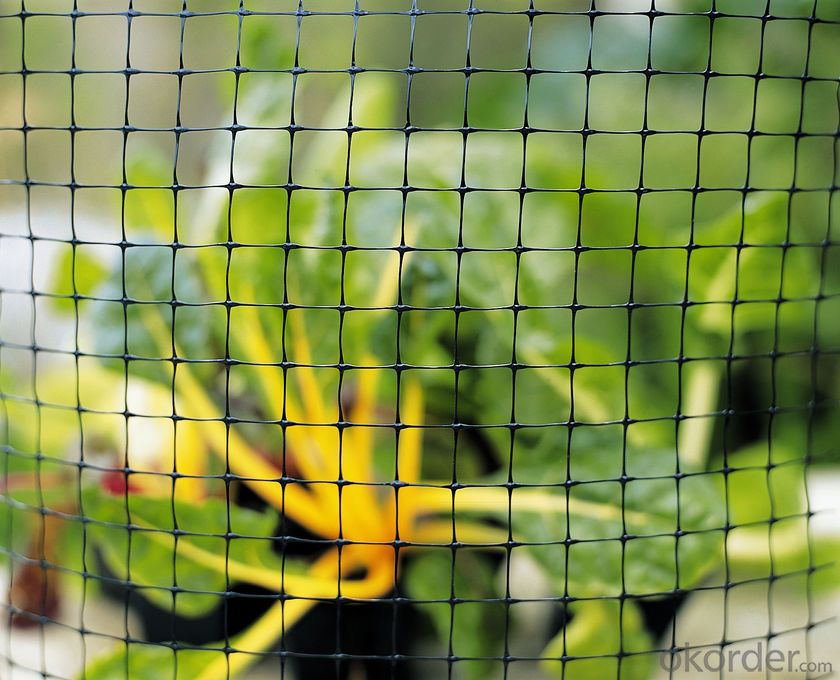

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- The specifications for geotextiles used in geosynthetic tubes may vary depending on the specific application and project requirements. However, some common specifications include factors such as the tensile strength, permeability, UV resistance, puncture resistance, and filtration properties. It is important to consider the specific project conditions and engineering design to determine the suitable specifications for geotextiles used in geosynthetic tubes.

- Q: Can geotextiles be used in mining applications?

- Yes, geotextiles can be used in mining applications. They are commonly used in mining operations for various purposes such as erosion control, slope stabilization, drainage, and filtration. Geotextiles help in preventing soil erosion, managing water flow, and enhancing the overall stability of mining sites. They are also used for lining tailings ponds and controlling sedimentation. Overall, geotextiles play a crucial role in improving the efficiency and environmental sustainability of mining operations.

- Q: Can concrete slabs be placed directly on geotextiles?

- The best pad gravel, professional geotextile manufacturers to answer,

- Q: Geotechnical construction of the weather when there is any requirement

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q: How do geotextiles contribute to soil filtration?

- Geotextiles contribute to soil filtration by acting as a physical barrier that allows water to pass through while filtering out sediment and other contaminants. They help to prevent soil erosion, improve water quality, and enhance the overall stability and sustainability of soil.

- Q: Geotextile grip test how to do? What is the step?

- Is said to be the strength test or the pull strength test. Can be based on relevant standards. For example: SL / T235-1999 standard, which has the relevant test method.

- Q: Are geotextiles resistant to biological degradation?

- Yes, geotextiles are generally resistant to biological degradation.

- Q: How do geotextiles help with soil separation in railway ballast systems?

- Geotextiles help with soil separation in railway ballast systems by preventing the mixing of different layers and ensuring the stability of the ballast. They act as a barrier between the ballast and subgrade, preventing the migration of fines from the subgrade into the ballast layer. This separation helps maintain the structural integrity of the railway track, reducing the risk of settlement and track deformations. Geotextiles also enhance drainage by allowing water to flow freely through the ballast layer, preventing waterlogging and maintaining the overall stability of the track.

- Q: What does geotextile mean?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. First, the characteristics: 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain full strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience, as the material light, soft, so the delivery, laying, construction convenience. 6, complete specifications: width of up to 9 meters. Is currently the widest product, the unit area quality: 100-1000g / ㎡. Second, the role: 1, isolation 2, filtration 3, drainage 4, reinforced 5, protection 6, anti-puncture

Send your message to us

Geotextile Brico Depot Deer Guard / Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords