Decorative Aluminum Metal Sheets AA1060 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1060 D.C Quality Used for Construction Description

Aluminum Sheets AA1060 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1060 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

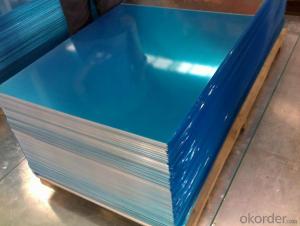

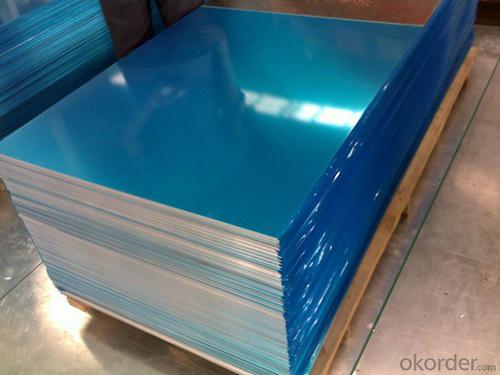

3.Aluminum Sheets AA1060 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1060 D.C Quality Used for Construction Specification

Alloy | AA1060 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1060 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1060 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1060 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can the aluminum sheets be used for soundproofing applications?

- Indeed, soundproofing applications can make use of aluminum sheets. As a lightweight and immensely reflective substance, aluminum possesses the capability to effectively obstruct and absorb sound waves. By incorporating aluminum sheets into soundproofing endeavors, one can contribute to the reduction of noise transmission and the creation of a more serene atmosphere. These sheets can be employed as barriers, panels, or even as constituents of composite materials to augment soundproofing attributes. Moreover, aluminum sheets exhibit durability, resistance to corrosion, and ease of upkeep, rendering them fitting for sustained utilization in diverse soundproofing applications.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- The density of gold is higher than the density of aluminum, so a kg of gold would take up less space than a kg of aluminum. But to answer your homework, you should look up the specific gravities of each of these metals, and figure out the volume of a kg of each....

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily bent, shaped, or formed without cracking or breaking. This property makes it an ideal choice for various applications where flexibility and customization are required. Aluminum sheets can be bent using various methods, such as using a brake press, roll forming, or by hand using specialized bending tools. The level of bendability may vary depending on the thickness and grade of the aluminum sheet, but in general, aluminum is known for its excellent formability and ability to be shaped into different configurations.

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are suitable for architectural applications. Aluminum is a versatile material that offers numerous advantages for architectural projects. It is lightweight, yet strong, making it easy to handle and install. Its corrosion-resistant properties make it well-suited for outdoor applications where it is exposed to the elements. Aluminum sheets can be easily formed into various shapes and sizes, allowing for creative and innovative architectural designs. They can be used for cladding, roofing, facades, and interior applications such as ceilings, partitions, and decorative elements. Additionally, aluminum sheets are available in a wide range of finishes, including anodized, painted, or coated, providing architects with the freedom to choose the desired aesthetic for their projects. These finishes can enhance the durability and color retention of the material, ensuring long-term performance and minimal maintenance requirements. Moreover, aluminum is a sustainable material as it is fully recyclable and has a low carbon footprint compared to other metals. This aligns with the increasing focus on environmentally-friendly construction practices in the architectural industry. In summary, aluminum sheets are highly suitable for architectural applications due to their lightweight, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes. Architects can confidently choose aluminum sheets to create visually appealing and durable structures.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: Can aluminum sheet be used for chemical processing?

- Aluminum sheet is indeed applicable for chemical processing. Its versatility and resistance to corrosion make it a sought-after material in various industries, including chemical processing. The remarkable attribute of aluminum is its ability to withstand numerous chemicals, such as acids, alkalis, and salts. Therefore, it is well-suited for situations where exposure to corrosive substances is prevalent. Moreover, aluminum possesses the advantages of being lightweight, long-lasting, and possessing excellent thermal conductivity. These qualities make it a prime choice for facilitating heat transfer and promoting energy-efficient procedures in chemical industries. However, it is crucial to assess the specific chemical environment and seek guidance from experts to guarantee the compatibility of aluminum with the particular chemicals and conditions involved in the process.

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Yes, aluminum sheets are suitable for manufacturing window frames.

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- 1988? Why do you believe it is aluminum? So far as I can recall, Performance didn't begin offering bicycles AT ALL until about 1992. Even then they had steel frames... their bikes were supplied by a Taiwanese company by the name of UEC who also made (and makes) KHS brand bikes. Regarding early aluminum failures, yes, there were many simply because factories were unfamiliar with the material and thought they could get away without the post treatment that a welded aluminum structure often requires. Another reason for aluminum frame failure was when a few factories attempted to bond aluminum tubes to lugs. This is also a problem with carbon fiber bikes. This is because the epoxy used degasses, or hardens and becomes crystallized. The now brittle epoxy cracks and results in catastrophic failure. This, in the factory's opinion, was not a warranty event. I'll tell you what. Grab a magnet off of your refrigerator and see if it sticks to the frame. if it does- even a tiny bit- then it is steel. If the frame is WELDED aluminum it should be retired since there is no way of telling whether the frame was properly post-treated. If the frame is BONDED then it should be retired because of the possibility of the epoxy fracturing.

Send your message to us

Decorative Aluminum Metal Sheets AA1060 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords