Laminated Aluminum Steel Sheets - AA1100 D.C Quality Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1100 D.C Quality Used for Construction Description

Aluminum Sheets AA1100 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1100 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

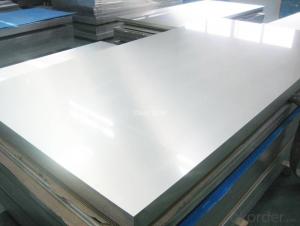

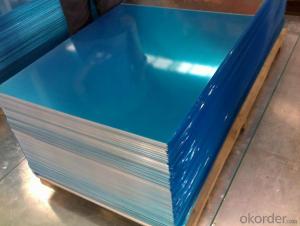

3.Aluminum Sheets AA1100 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1100 D.C Quality Used for Construction Specification

Alloy | AA1100 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1100 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1100 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1100 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: Can aluminum sheets be used for solar reflectors?

- Yes, aluminum sheets can be used for solar reflectors. Aluminum is highly reflective and has excellent heat resistance, making it an ideal material for solar reflectors. The reflective surface of aluminum sheets helps to redirect and concentrate sunlight onto solar panels or other solar devices, maximizing their energy efficiency. Additionally, aluminum is lightweight and durable, making it easy to handle and suitable for outdoor applications.

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- If not missing the cost or use aluminum plate, because the fluorine content of fluorocarbon metal paint paint factory production lot are not enough, so the warranty 10-15 years is just a pretext, and the construction of the technical requirements for workers is relatively high.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a popular material for balcony railings due to its lightweight nature, durability, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and designs, making it suitable for various architectural styles. Additionally, aluminum railings require minimal maintenance and can withstand harsh weather conditions, making them a practical and long-lasting choice for balcony railings.

- Q: Can aluminum sheet be used for solar panels?

- Absolutely! When it comes to solar panels, aluminum sheet is a fantastic choice. Thanks to its remarkable strength, durability, and lightweight nature, aluminum is a widely favored material for constructing these panels. Its versatility shines through as it serves as both the frame and mounting structure, providing unparalleled support and stability. Moreover, its exceptional resistance to corrosion is a crucial factor given the panels' exposure to the elements. On top of all that, aluminum's highly conductive properties allow for efficient electricity transfer from the solar cells within the panel. All in all, incorporating aluminum sheet into solar panel construction significantly enhances their performance, longevity, and overall efficiency.

- Q: Is it possible to use aluminum sheets as a material for exterior siding or cladding on buildings?

- <p>Yes, aluminum sheets are commonly used for siding or cladding due to their durability, lightweight, and resistance to corrosion. They are low maintenance, can be easily shaped, and come in various colors and finishes. Aluminum's resistance to weathering and its ability to withstand temperature extremes make it a popular choice for both residential and commercial buildings.</p>

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- To dig the Elven blood machine at the Pocket Monster Center

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Indeed, 101 aluminum sheets possess the potential to serve as a valuable resource in the creation of sporting goods. The versatility of aluminum as a material grants numerous advantages to sporting equipment. Notably, its lightweight nature becomes paramount when it comes to various sports gear such as bicycles, tennis rackets, and baseball bats. This attribute facilitates effortless handling and enhances maneuverability. Furthermore, aluminum boasts corrosion resistance, ensuring the durability of sporting goods even when exposed to diverse weather conditions. Moreover, its exceptional strength-to-weight ratio renders it suitable for high-performance equipment, enabling durability without unnecessary bulk. Consequently, the utilization of 101 aluminum sheets emerges as a viable option for manufacturing a wide range of sporting goods, effectively delivering the desired properties essential for optimum performance, longevity, and user satisfaction.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and formability. It offers durability and structural integrity while keeping the weight of the aircraft relatively low. Aluminum sheets are commonly used for constructing aircraft panels, providing a reliable and efficient solution for aerospace applications.

Send your message to us

Laminated Aluminum Steel Sheets - AA1100 D.C Quality Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords