Aluminum 4x8 Sheets - Pre-Painted Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Pre-painted Coils Aluminium Coils

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Aluminium Pre-painted Coils Aluminium Coils

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Pre-painted Coils Aluminium Coils

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

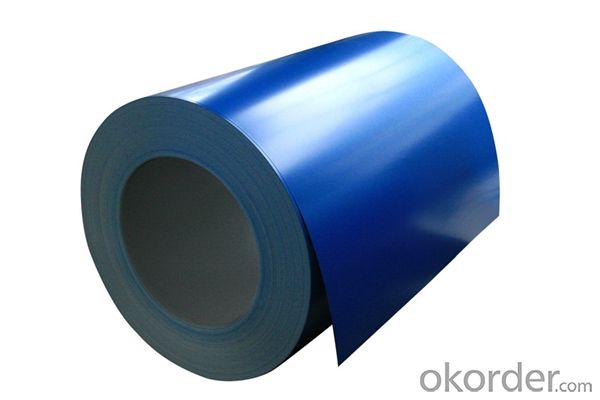

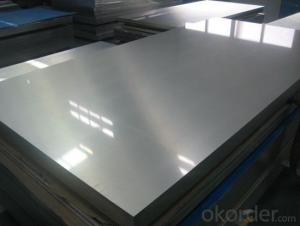

5. Image of Aluminium Pre-painted Coils Aluminium Coils

6. Package and shipping of Aluminium Pre-painted Coils Aluminium Coils

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How many molecules are in 1 square foot of aluminum foil?

- Since aluminum foil is an amalgamation of various metals you would first need to know the full chemical breakdown in order to determine how many molecules there are in a square foot of aluminum foil. That said, if your foil was 100% aluminum, you could determine the number of AL atoms by first determining the mass of the foil and dividing by the molecular weight of AL. Multiply that by 6.022 x 10^23 to determine the number of atoms.

- Q: What are the different methods of forming aluminum sheet?

- Aluminum sheet can be formed using various methods, each with its own advantages and limitations. 1) Rolling is the most commonly used method for manufacturing aluminum sheet. It involves passing aluminum ingots through rolling mills, gradually reducing the thickness until the desired sheet thickness is achieved. Rolling is highly versatile, allowing for precise thicknesses and a wide range of sizes. 2) Extrusion involves forcing a heated aluminum billet through a die to create a continuous sheet. This method is often used to produce sheets with complex cross-sectional shapes and consistent thickness. It is ideal for creating aluminum sheets with consistent patterns or textures. 3) Casting entails pouring molten aluminum into a mold and allowing it to solidify. It is commonly used for producing large aluminum sheets with irregular shapes or intricate designs. However, the thickness of cast aluminum sheets may not be as consistent as those created through rolling or extrusion. 4) Stretch forming involves clamping a sheet of aluminum around its edges and stretching it over a die to achieve the desired shape. This method is commonly used for producing curved or contoured aluminum sheets, such as those used in automotive or aerospace applications. 5) Spinning utilizes a rotating disk or mandrel pressed against a sheet of aluminum to shape it into the desired form. This method is frequently employed to create cylindrical or conical aluminum sheets, like those seen in lighting fixtures or cookware. 6) Deep drawing involves placing a flat sheet of aluminum into a die and using a punch to force the metal into the desired shape. It is commonly used for producing aluminum sheets with deep, cup-like shapes, such as those found in beverage cans or automotive parts. Ultimately, the choice of method for forming aluminum sheet depends on factors such as the desired shape, thickness, and complexity of the final product, as well as production volume and cost considerations.

- Q: What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

- Q: Which kind of glue can bond two pieces of aluminum sheets?

- you can use jellied universal glue, don't use the liquid one, because it's only suitable for plastics or materials easy for erosion.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- Mig Welding Aluminum Without Gas

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, is a popular printing technique that involves transferring an image from a plate onto a rubber blanket and then onto the printing surface. Aluminum sheets are commonly used as the base material for lithographic plates due to their excellent durability, lightweight nature, and ability to hold fine details. The aluminum sheets used for lithographic printing are typically coated with a photosensitive emulsion, which allows the image to be transferred onto the printing surface with precision and accuracy. This makes aluminum sheets an ideal choice for lithographic printing, especially for high-quality and large-scale printing projects.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a durable and lightweight material that is resistant to corrosion and easy to clean, making it a popular choice for food preparation. However, it is important to note that aluminum can react with certain acidic or salty foods, so it is recommended to use a protective barrier such as parchment paper or silicone mats when working with such ingredients.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets are known for their excellent creep resistance. Creep is the tendency of a material to slowly deform under a constant load over time. Compared to other metals, such as steel, aluminum has a relatively low creep rate, meaning it deforms at a slower rate under the same load and temperature conditions. This makes aluminum sheets suitable for applications requiring dimensional stability and resistance to long-term deformation. Additionally, aluminum's low creep resistance allows it to withstand high temperatures without significant deformation, making it suitable for use in various industries, including aerospace, automotive, and construction. However, it is important to note that the creep resistance of aluminum sheets can vary depending on the alloy used, heat treatment, and other factors, so it is essential to choose the appropriate aluminum alloy and design for specific applications to optimize creep resistance.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers. Aluminum is a lightweight and highly conductive material, making it an ideal choice for heat transfer applications. Its excellent thermal conductivity allows for efficient heat transfer, resulting in effective cooling or heating processes. Additionally, aluminum is corrosion-resistant, which is crucial for heat exchangers that come in contact with various fluids. The malleability and formability of aluminum sheets also make them easy to shape into the required designs for heat exchanger components. Overall, aluminum sheets offer several advantages for manufacturing heat exchangers, making them a suitable choice for this application.

Send your message to us

Aluminum 4x8 Sheets - Pre-Painted Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords