Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coil/PPGL Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coil

1. Detailed Specifications:

| Product | Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coils

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

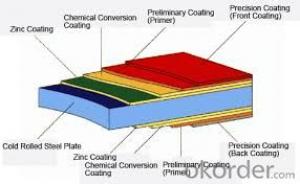

3. Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coil Image:

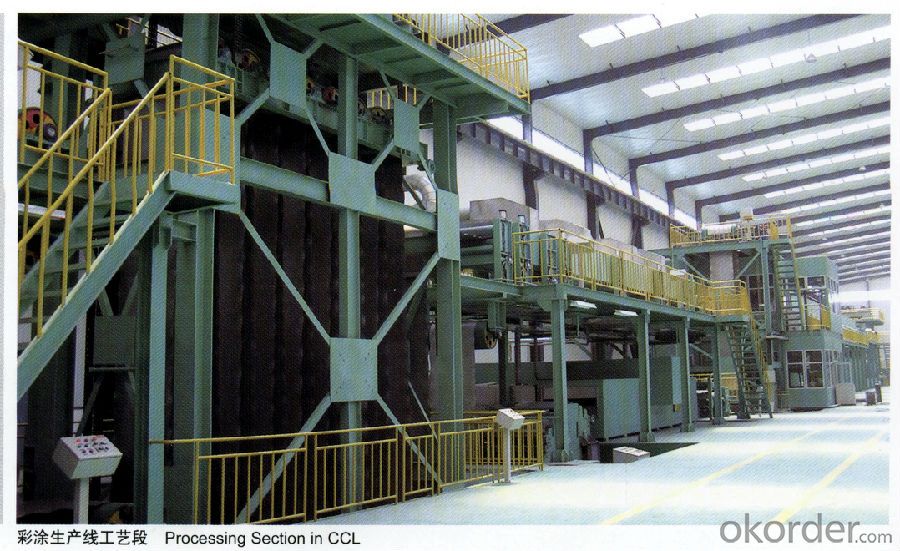

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What are the safety precautions when working with steel coils?

- Some safety precautions when working with steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper lifting techniques to prevent musculoskeletal injuries, maintaining a clear and organized work area to avoid tripping hazards, using proper machinery and equipment to handle and transport the coils safely, and following established safety protocols and procedures. It is also important to receive proper training and supervision to handle steel coils effectively and minimize potential risks.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- steel wool = iron fibers and rusts easily in air iron + Oxygen BUT the blue soap protects the iron at first. that needs to be cleaned off. damp surfaces speed the rusting but compeletly underwater there is not much O2, ther eis some temperature has an effect. the rusting depends ofn the area of the fibers which does NOT change when you cut th epad in smaller pieces. a good beginners experiment In old times thye thought the rusted material would lose weight becasuse it was not solid iron any more careful experiments showed it gained weight and lead to and understanding of chemistry

- Q: What are the dimensions of steel coils used in the power generation industry?

- The dimensions of steel coils used in the power generation industry vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry are typically in the range of 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coil can vary, but it is often in the range of several hundred to several thousand meters.

- Q: looking for a good pocket knife. i keep going through these 440 steel pocket knives with every day work usage. this will be my 4th. even when i use a whetstone they stay sharp for a short period of time but the edge does not last, 440 is too soft! what is a good steel to look for in a pocket knife? also what are some good brands. ive been using gerber and buck sofar. if you could recommend me a few mid/small sized knives i would greatly appreciate it!

- Best Steel For Pocket Knife

- Q: What are the different types of welding methods used for steel coils?

- There are several types of welding methods used for steel coils, including: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it uses a flux-coated electrode to create an arc between the electrode and the base metal, forming a weld. 2. Gas Metal Arc Welding (GMAW): Also called MIG welding, it uses a continuous wire electrode and a shielding gas, typically argon or a mixture, to create a weld. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, but instead of a solid wire electrode, it uses a tubular electrode filled with flux, which provides additional shielding and can be used with or without a shielding gas. 4. Submerged Arc Welding (SAW): It involves a continuous wire electrode and a granular flux that is fed under a layer of flux, creating a submerged arc and a highly efficient weld. 5. Resistance Welding: It utilizes electricity to generate heat and pressure, joining the steel coils together. Types of resistance welding include spot welding, seam welding, and projection welding. Each welding method has its own advantages and limitations, and the choice depends on factors such as the specific requirements of the steel coils, the thickness of the material, and the production process.

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin.

- Q: But we've had a problem with bears being attracted to the water in the Intex Inflatable pools, the bear would come at night every so often and push on the sides letting out the water.Would a bear be able to bend a steel frame before I go and spend money?

- depends on the steel thickness and positioning. frm your question I'm guessing you're not really well versed in steel framing or use... im guessing whatever you build, a bear can destroy. if i was to build it not even 100 bears can destroy it. it doesn't require much steel, it's just about bracing the positing of steel and some design.

- Q: How do steel coils contribute to the oil and gas industry?

- Steel coils are an essential component in the oil and gas industry as they are used to manufacture various equipment and structures like pipelines, storage tanks, and drilling rigs. These coils provide the necessary strength, durability, and resistance to corrosion required for the harsh operating conditions in the industry. Additionally, steel coils are crucial in the transportation of oil and gas as they are used in the construction of tankers and pipelines, ensuring the safe and efficient movement of these valuable resources.

- Q: What is the average thickness tolerance for steel coils?

- The average thickness tolerance for steel coils can vary depending on the specific industry and application. However, a common average thickness tolerance for steel coils is typically around ±0.005 to ±0.010 inches.

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Guitars okorder /

Send your message to us

Customized Long Durable Decorative Color Coated Galvanized PPGI Steel Coil/PPGL Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords