Hot Dipped Galvanized Steel Coils for Roofing Sheet SGCC (DX51D+Z)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard:

The hot dip galvanizing process is developed from old hot plating methods, and it has a history of over 140 years since its application to the industry of France in 1836. However, the hot dip galvanizing industry has been greatly developed in recent three decades with the quick development of cold-strip steel.

2.Main features of Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard:

With excellent cold-rolling steel strips as a base material, it has the advantages of

.Passivation and oil coating treatment.

.Avoids deterioration after a short-term storage in a warehouse.

.After the surface is cleaned, the product is a good base material for manufacturing anti-corrosion coating plates.

3.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Images:

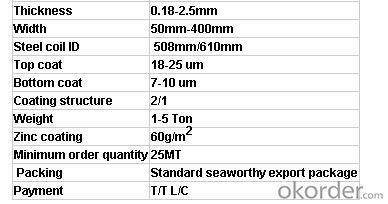

4.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Specification:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment for coils, including slitters, cut-to-length lines, leveling machines, coil cars, and stackers. Slitters are used to cut wide coils into narrower strips, while cut-to-length lines can cut coils into specific lengths. Leveling machines are used to flatten and remove any imperfections on the surface of the coils. Coil cars are used to transport the coils within the processing facility, and stackers are used to neatly stack the coils for storage or transportation.

- Q: How are steel coils inspected for bendability using bend testers?

- Bend testers are specialized machines utilized to inspect the bendability of steel coils, measuring their flexibility and resistance against bending. The inspection process involves multiple steps to guarantee precise and dependable outcomes. To begin with, the steel coil is prepared by securing it firmly in place, typically using clamps or other mechanisms to prevent any movement during testing. This ensures stability and enables consistent and repeatable measurements. Following that, the bend tester is set up according to the specified testing parameters. These parameters usually include the desired bend angle, the speed at which the bend is applied, and the number of cycles to be performed. The bend tester is equipped with a bending mechanism that applies a controlled force on the coil, simulating the bending conditions it may experience in its application or use. Once the bend tester is ready, the bending process commences. The machine gradually applies an increasing force to the steel coil until it reaches the desired bend angle. Careful measurement and monitoring of this force take place throughout the process to ensure accuracy. While the bending process is underway, the machine records and displays significant data, such as the applied force, the angle of bend, and any indications of cracking or other defects. This data is crucial for evaluating the bendability of the steel coil and determining its compliance with required standards. Once the desired bend angle is attained, the coil is released from the bending mechanism, allowing any residual stresses to relax. This relaxation period is essential for observing any potential spring-back effect, where the coil partially returns to its original shape after bending. The amount of spring-back is also measured and recorded for further analysis. Finally, the inspection results are analyzed to assess the overall bendability of the steel coil. If the coil meets the specified bendability criteria, it can be deemed acceptable for its intended application. However, if any cracks, fractures, or excessive spring-back are detected, further investigation and analysis may be necessary to identify the cause and determine appropriate corrective actions. In conclusion, bend testers play a crucial role in inspecting the bendability of steel coils. Through a controlled and systematic process, these machines accurately measure flexibility and resistance to bending, ensuring the quality and reliability of steel coils used in various industries.

- Q: What are the different types of steel coil coating materials?

- There exist various steel coil coating materials utilized in diverse industries and applications. Some frequently encountered types encompass: 1. Polyester: Renowned for their resilience and ability to withstand weathering, polyester coil coating materials find frequent application in outdoor settings like roofing and cladding. They offer exceptional protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials exhibit remarkable resistance to chemicals, UV radiation, and weathering. They are commonly employed in architectural contexts, providing prolonged color retention and excellent defense against harsh environmental conditions. 3. Polyurethane: Possessing a high degree of flexibility and adhesion, polyurethane coil coating materials prove ideal for scenarios necessitating resistance to abrasion, impact, and bending. The automotive and appliance industries commonly rely on them. 4. Epoxy: Epoxy coil coating materials are celebrated for their remarkable adhesion and corrosion resistance. Industries such as metal furniture, storage tanks, and machinery frequently utilize them to ensure long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the robustness of polyester with the flexibility of silicone. They are prevalent in agricultural and industrial settings, offering outstanding resistance to chipping, cracking, and peeling. These merely serve as a few instances of the diverse array of steel coil coating materials currently available in the market. The selection of a coating material hinges upon the specific requirements of an application, including durability, weather resistance, chemical resistance, and aesthetics.

- Q: What are the common surface finishes for steel coils?

- There are several common surface finishes for steel coils, depending on the specific requirements and applications. Some of the most common surface finishes for steel coils include: 1. Hot-dip galvanized: This is a process where the steel coil is immersed in a bath of molten zinc, coating the surface with a protective layer. Hot-dip galvanizing provides excellent corrosion resistance and is commonly used in outdoor applications. 2. Electro-galvanized: In this process, a thin layer of zinc is electroplated onto the surface of the steel coil. Electro-galvanizing provides good corrosion resistance and a smooth finish, making it suitable for various applications, including automotive parts and appliances. 3. Galvannealed: Galvannealed steel coils are coated with a zinc-iron alloy by passing them through a high-temperature annealing process. This finish offers improved paint adhesion and excellent resistance to corrosion, making it suitable for manufacturing automotive parts and construction materials. 4. Tinplate: Tinplating involves coating the steel coil with a thin layer of tin, providing excellent corrosion resistance and a bright, shiny appearance. Tinplate is commonly used for packaging materials and cans. 5. Pre-painted: Pre-painted steel coils have a layer of paint applied to the surface, providing both corrosion resistance and an aesthetically pleasing finish. This finish is often used for building materials, such as roofing and siding. 6. Cold-rolled: Cold-rolled steel coils undergo a process where they are rolled at room temperature, resulting in a smooth, clean surface. Cold-rolled coils are typically used in applications where a high-quality surface finish is required, such as automotive parts and appliances. These are just a few of the common surface finishes for steel coils. The choice of finish depends on the desired properties, such as corrosion resistance, appearance, and specific application requirements.

- Q: like, what can steel make?

- buildings bridges automobiles elevators railroads and railroad equipment appliances and many many more. Steel is used almost everywhere. reference: Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars (Despite growth in usage of aluminium, it is still the main material for car bodies.), steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.[66] Other common applications include shipbuilding, pipeline transport, mining, offshore construction, pipeline transport, aerospace, white goods (e.g. washing machines), heavy equipment (e.g. bulldozers), office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better known as rolled homogeneous armour in this role). .

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q: Obviously this is an easy question for anyone who works with metal. However, I am currently writing a book and had an idea that had to do with these two metals. Is it possible for gold to be folded into steel while it is being forged? Do 3-metal alloys exist? If this is not possible with current metal-working techniques and technology, what would be needed to make it possible? And finally, what exactly would the mixing of these two yield? A weak metal? A brittle metal? How would it compare to iron or gunmetal? If you have no idea, please offer speculations. Thank you!

- Not okorder /

- Q: How are steel coils protected from condensation?

- Steel coils are protected from condensation through a variety of methods including the application of moisture-resistant coatings, the use of desiccants or drying agents, and the implementation of proper storage and handling techniques such as maintaining appropriate temperatures and humidity levels.

- Q: What are the different methods of coil recoiling for narrow strip widths?

- Some of the different methods of coil recoiling for narrow strip widths include slitting and rewinding, oscillating winding, and turret winding.

- Q: How do steel coils contribute to sustainability in manufacturing?

- Steel coils contribute to sustainability in manufacturing in several ways: 1. Recyclability: Steel is one of the most recycled materials in the world, with a recycling rate of over 90%. Steel coils are made from recycled steel and can be recycled again at the end of their life cycle. This reduces the need for extracting raw materials, conserves natural resources, and reduces energy consumption and greenhouse gas emissions associated with steel production. 2. Durability: Steel is known for its strength and durability. Steel coils are designed to withstand heavy loads, extreme temperatures, and harsh environmental conditions. This means that products made from steel coils, such as automotive parts, construction materials, and appliances, have a longer lifespan, reducing the need for frequent replacements and minimizing waste. 3. Energy efficiency: Steel coils are used in various manufacturing processes, such as stamping, forming, and welding. These processes require less energy when working with steel coils compared to other materials. Steel's high strength-to-weight ratio allows for the production of lightweight yet strong components, reducing energy consumption during transportation and improving fuel efficiency in vehicles. 4. Reduced emissions: Steel coils contribute to sustainability by helping manufacturers reduce their emissions. Steel is a low-carbon material, and its production emits fewer greenhouse gases compared to other materials like aluminum or plastics. By using steel coils, manufacturers can reduce their carbon footprint and contribute to climate change mitigation efforts. 5. Circular economy: Steel coils are a key component in the circular economy, which aims to minimize waste and maximize resource efficiency. Steel coils can be easily recycled and reused, ensuring that they remain in the production cycle for a longer time. This reduces the need for virgin materials and promotes a more sustainable and circular approach to manufacturing. In conclusion, steel coils contribute to sustainability in manufacturing by being recyclable, durable, energy-efficient, emission-reducing, and promoting a circular economy. By choosing steel as a material and utilizing steel coils, manufacturers can make significant strides towards reducing their environmental impact and fostering a more sustainable manufacturing industry.

Send your message to us

Hot Dipped Galvanized Steel Coils for Roofing Sheet SGCC (DX51D+Z)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords