Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Description of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

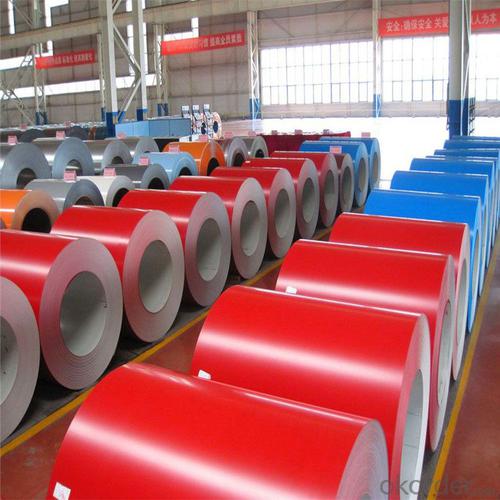

Products Show of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different methods of surface coloring for special steel?

- Special steel can be colored using several different methods, each with its own purpose and effect. Some common methods include: 1. Heat treatment: This technique involves subjecting the steel to high temperatures, which causes controlled oxidation on the surface. The result is a layer of colored oxide, ranging from golden yellow to deep blue or black. Heat treatment also enhances hardness and corrosion resistance. 2. Electroplating: By immersing the steel in an electrolyte bath with a metal salt solution and passing an electric current through it, metal ions adhere to the surface, creating a thin layer of the desired metal coating. This method allows for a wide range of colors and finishes. 3. Chemical coloring: This process involves using chemical solutions to change the surface color of special steel. Treating the steel with a solution containing specific chemicals, such as oxidizing agents or dyes, can produce various colors and finishes, often used for decorative purposes. 4. Physical Vapor Deposition (PVD): PVD is a technique that deposits thin layers of material onto the steel surface. A solid material is vaporized using a high-energy source and then condensed onto the steel. This allows for the deposition of different materials, resulting in various colors and finishes. PVD coatings are durable, wear-resistant, and aesthetically appealing. 5. Laser marking: Laser marking uses a focused laser beam to create permanent markings or colors on the steel surface. By adjusting laser parameters, such as power and speed, different colors and effects can be achieved. Laser marking is ideal for branding, identification, or decorative purposes due to its precision and ability to create intricate designs. The choice of surface coloring method for special steel depends on factors like desired color, durability, functionality, and cost considerations. Each method has its advantages and limitations, allowing for customization based on specific requirements and preferences.

- Q: How is special steel used in the construction supply chain?

- Special steel is used in various ways in the construction supply chain. It is commonly used in the production of high-quality tools and equipment used in construction, such as drills, saws, and hammers. Special steel is also utilized in the manufacturing of structural components, such as beams and columns, which provide strength and durability to buildings and infrastructure projects. Additionally, it is used in the production of reinforcing bars and wire mesh, which reinforce concrete structures and ensure their stability. Overall, special steel plays a crucial role in enhancing the performance and safety of construction materials and products in the supply chain.

- Q: What are the different mechanical properties of special steel?

- Special steels exhibit a diverse array of mechanical characteristics that render them distinctive and well-suited for specific uses. Among the noteworthy mechanical properties of special steel are its exceptional strength, impressive toughness, commendable wear resistance, and superior corrosion resistance. Of all these properties, high strength emerges as a particularly crucial attribute of special steel. This inherent strength enables the material to withstand substantial loads and stress without succumbing to deformation or failure. As a result, special steel finds application in areas where the preservation of structural integrity and durability holds paramount importance, such as in the construction of buildings, bridges, and machinery. Another significant mechanical property of special steel lies in its toughness. This quality refers to the material's ability to absorb energy and withstand fracture when subjected to impact or sudden loads. Special steels possessing high toughness become indispensable in applications involving dynamic and high-impact forces, such as the fabrication of tools, gears, and machinery components. Wear resistance constitutes yet another critical mechanical property of special steel. It denotes the material's capacity to endure damage and deterioration caused by friction, abrasion, or erosion. Special steel boasting good wear resistance frequently finds employment in scenarios where it will be exposed to harsh conditions or repetitive mechanical actions, as witnessed in the manufacturing of cutting tools, dies, and molds. Of equal importance is the superior corrosion resistance offered by special steel. This mechanical property proves invaluable, particularly in environments where exposure to moisture, chemicals, or extreme temperatures looms likely. Special steels endowed with high corrosion resistance can withstand the adverse effects of oxidation, rust, and chemical reactions, rendering them eminently suitable for deployment in industries such as marine, chemical, and oil and gas. In conclusion, special steels possess a diverse range of mechanical properties that distinguish them from conventional steels. High strength, remarkable toughness, commendable wear resistance, and superior corrosion resistance represent a few of these key mechanical properties, rendering special steel the preferred choice for numerous industrial applications.

- Q: How is special steel used in the manufacturing of machinery?

- Special steel is used in the manufacturing of machinery due to its unique properties and characteristics. It provides exceptional strength, durability, and resistance to wear and corrosion, making it suitable for critical components such as gears, shafts, bearings, and cutting tools. Special steel also allows for precise machining and shaping, enabling the production of complex machine parts. Overall, special steel enhances the performance and reliability of machinery, ensuring efficient and long-lasting operation.

- Q: What are the main applications of special steel in the semiconductor industry?

- Special steel is widely used in the semiconductor industry for various applications. One of the main applications is in the production of wafer fabrication equipment, such as vacuum chambers, deposition tools, and etching systems. The high strength, corrosion resistance, and thermal stability of special steel make it suitable for these critical components that operate under extreme conditions. Additionally, it is also used in the manufacturing of precision molds and dies required for semiconductor packaging processes. Overall, special steel plays a vital role in ensuring the reliability, performance, and quality of semiconductor manufacturing processes.

- Q: Can special steel be used in the renewable energy sector?

- Indeed, the renewable energy sector can effectively utilize special steel. This type of steel, also referred to as alloy steel, offers improved qualities such as exceptional strength, longevity, and resistance to corrosion, rendering it suitable for a diverse range of applications within renewable energy technologies. Within the realm of wind energy, special steel is employed for the production of wind turbine components. Wind turbine towers necessitate materials that are both robust and lightweight in order to withstand the dynamic loads and harsh environmental conditions they encounter. Special steel alloys, including high-strength low-alloy (HSLA) steel, provide the requisite strength-to-weight ratio, thereby ensuring the structural integrity of wind turbine towers. Furthermore, special steel proves advantageous in the field of solar energy. Concentrated solar power (CSP) plants rely on mirrors or lenses to concentrate sunlight, generating intense heat for the purpose of electricity generation. In the construction of these components, special steel alloys possessing high thermal conductivity and the ability to withstand high temperatures are employed. This ensures efficient energy capture and durability. In addition, special steel plays a crucial role in the manufacturing of equipment for hydroelectric power generation. Turbine components, such as blades, shafts, and runners, necessitate materials with exceptional strength and resistance to erosion and cavitation. Special steel alloys, including stainless steel and tool steel, exhibit these characteristics, guaranteeing the longevity and reliability of hydroelectric power systems. In summary, special steel finds widespread application within the renewable energy sector. Its qualities, such as high strength, durability, and resistance to corrosion, make it suitable for use in wind energy, solar energy, and hydroelectric power generation. Through the utilization of special steel, the renewable energy sector can enhance the performance, efficiency, and lifespan of various renewable energy technologies.

- Q: What are the specific requirements for special steel used in the aerospace fastener industry?

- To ensure the safety, reliability, and performance of aircraft components, the aerospace fastener industry demands special steel that meets specific criteria. These requirements include the following: 1. Remarkable strength: The special steel used in aerospace fasteners must possess exceptional strength to withstand the extreme forces and stresses experienced during flight. This is crucial for maintaining the structural integrity of aircraft components. 2. Resistance to corrosion: Aerospace fasteners are constantly exposed to various environmental conditions, including moisture, high temperatures, and chemicals. Therefore, the steel used must have excellent corrosion resistance properties to prevent degradation and maintain the longevity of the fasteners. 3. Exceptional fatigue resistance: Due to repeated loading and unloading cycles throughout the lifespan of aircraft components, the special steel used in aerospace fasteners must exhibit exceptional fatigue resistance. This ensures that the fasteners can endure cyclic loading without fracturing or experiencing any structural failures. 4. Ability to withstand temperature variations: Aerospace fasteners are subject to extreme temperature changes, ranging from sub-zero temperatures at high altitudes to elevated temperatures near engines. The steel used should possess excellent temperature resistance to maintain its mechanical properties under these conditions. 5. Lightweight nature: In the aerospace industry, weight reduction plays a crucial role in improving fuel efficiency and increasing the payload capacity of aircraft. Therefore, special steel used in aerospace fasteners should be lightweight without compromising on strength and other necessary properties. 6. Non-magnetic features: Certain aerospace applications require non-magnetic fasteners to prevent interference with sensitive electronic equipment, such as avionics and navigation systems. Consequently, the special steel used in such cases must exhibit non-magnetic characteristics. 7. Adherence to industry standards: Special steel used in the aerospace fastener industry must meet the stringent standards and specifications established by regulatory bodies like the International Organization for Standardization (ISO) and the National Aerospace and Defense Contractors Accreditation Program (NADCAP). Complying with these standards ensures the quality and reliability of the fasteners. Overall, meeting the specific requirements for special steel used in the aerospace fastener industry is paramount to ensuring the safety and performance of aircraft components. These requirements encompass high strength, corrosion resistance, fatigue resistance, temperature resistance, lightweight properties, non-magnetic characteristics, and compliance with industry standards.

- Q: What is the cost of special steel compared to other materials?

- The price of special steel can vary depending on various factors when compared to other materials. Special steel, also known as alloy steel or tool steel, is generally more expensive than regular carbon steel due to its superior properties and composition. Its strength, durability, and resistance to wear and corrosion make it ideal for specialized applications in industries like automotive, aerospace, and construction. In comparison to non-ferrous metals like aluminum or copper, special steel often has a lower cost. However, it is important to note that different types of special steel can have different price ranges. For example, stainless steel, which contains chromium and other elements for better corrosion resistance, tends to be pricier than carbon steel. When comparing the cost of special steel to materials like plastics or composites, it is crucial to assess the specific project requirements. While these alternatives may have lower initial costs, they may not possess the same level of strength, heat resistance, or durability as special steel. Therefore, the long-term benefits and savings offered by special steel, such as reduced maintenance, longer lifespan, and improved performance, should also be considered. Ultimately, the price of special steel compared to other materials is influenced by factors such as the type and grade of steel, market demand, quantity needed, and any additional processing or finishing required. Consulting with suppliers, considering the specific application requirements, and conducting a comprehensive cost-benefit analysis will help determine the most suitable and cost-effective material choice for a particular project.

- Q: What are the main advantages of using special steel in the power generation industry?

- The main advantages of using special steel in the power generation industry are its exceptional strength, resistance to corrosion and high-temperature capabilities. These properties make special steel highly suitable for critical components like turbines, boilers, and generators, ensuring their durability and reliability in harsh operating conditions. Additionally, special steel's ability to withstand extreme pressure and stress enhances the overall safety and efficiency of power plants.

- Q: What are the different annealing techniques used for special steel?

- Some of the different annealing techniques used for special steel include full annealing, process annealing, spheroidizing annealing, and stress relieving annealing. Full annealing involves heating the steel to a temperature above its critical point and then slowly cooling it to room temperature. Process annealing is used to improve the machinability of the steel by heating it to a lower temperature and then cooling it in a controlled manner. Spheroidizing annealing is used to soften the steel and improve its ductility by heating it to a temperature just below its critical point and then cooling it slowly. Stress relieving annealing is used to reduce internal stress in the steel by heating it to a temperature below its critical point and then cooling it slowly.

Send your message to us

Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords