Custom Aluminum Profiles for Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile of Casting Material for Windows Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Casting Material for Windows:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

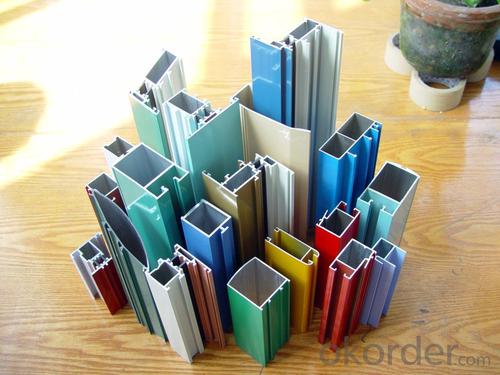

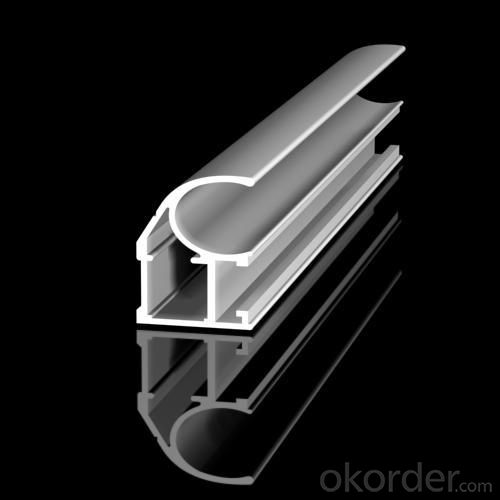

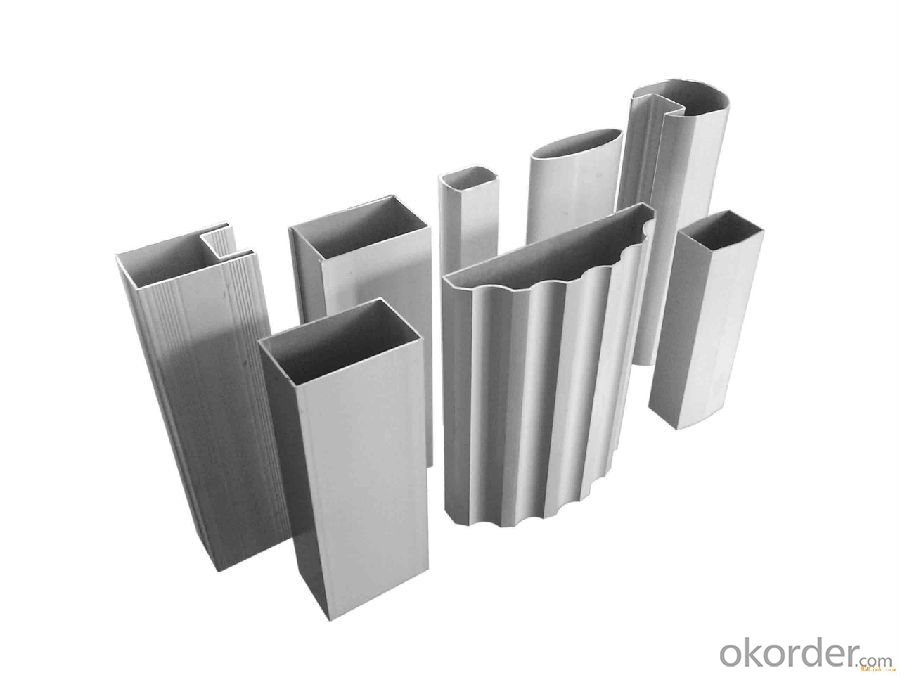

3.Aluminium Profile of Casting Material for Windows Images:

4.Aluminium Profile of Casting Material for Windows Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the advantages of using aluminum profiles in the mining industry?

- There are several advantages of using aluminum profiles in the mining industry. Firstly, aluminum is a lightweight material, which makes it easier to transport and install in remote mining locations. Additionally, aluminum profiles are highly durable and resistant to corrosion, making them suitable for harsh mining environments. They also offer excellent thermal conductivity, allowing for efficient heat dissipation in heavy machinery. Furthermore, aluminum profiles can be easily molded and customized, providing flexibility in designing mining infrastructure. Lastly, aluminum is a sustainable and recyclable material, aligning with the growing demand for eco-friendly practices in the mining industry.

- Q: How do aluminum profiles perform in load-bearing structures?

- Aluminum profiles are known for their excellent performance in load-bearing structures. Due to their high strength-to-weight ratio, aluminum profiles offer significant advantages over other materials in terms of structural integrity and overall weight reduction. The inherent strength of aluminum profiles enables them to support heavy loads, making them suitable for various load-bearing applications. Whether it is in buildings, bridges, or industrial structures, aluminum profiles can effectively withstand and distribute heavy loads, ensuring reliable and safe performance. Additionally, aluminum profiles have exceptional corrosion resistance, which is crucial for load-bearing structures exposed to harsh environments or outdoor conditions. This corrosion resistance ensures the longevity and durability of the structure, reducing maintenance and replacement costs in the long run. Furthermore, aluminum profiles are highly versatile and can be easily customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for efficient integration into complex load-bearing structures. This versatility also enables the use of aluminum profiles in unique architectural designs, enhancing the aesthetics of the structure. Another advantage of aluminum profiles in load-bearing structures is their lightweight nature. Compared to traditional materials like steel, aluminum profiles are significantly lighter, resulting in easier and more cost-effective transportation, installation, and overall construction process. This makes aluminum profiles an ideal choice for projects where weight reduction is a priority. In conclusion, aluminum profiles excel in load-bearing structures due to their high strength-to-weight ratio, corrosion resistance, versatility, and lightweight properties. These characteristics make aluminum profiles a reliable and efficient choice for various load-bearing applications, providing durability, longevity, and cost-effectiveness to the overall structure.

- Q: Can aluminum profiles be used for curtain wall systems?

- Yes, aluminum profiles can be used for curtain wall systems. In fact, aluminum is one of the most commonly used materials for curtain wall construction due to its numerous advantages. Aluminum profiles offer excellent strength and durability, making them capable of supporting the weight of large glass panels. Additionally, aluminum is highly resistant to corrosion, which is essential for exterior applications where the curtain wall is exposed to various weather conditions. Moreover, aluminum profiles can be easily extruded into various shapes and sizes, allowing for design flexibility and customization. The lightweight nature of aluminum also makes it easier to handle and install, reducing labor and transportation costs. Furthermore, aluminum is a sustainable material as it is recyclable, contributing to the overall sustainability of the curtain wall system. Overall, aluminum profiles are a suitable choice for curtain wall systems due to their strength, durability, corrosion resistance, design flexibility, and sustainability.

- Q: Can aluminum profiles be used for trade show booths?

- Indeed, trade show booths can utilize aluminum profiles. These profiles, being lightweight and durable, lend themselves well to customization, accommodating a wide range of shapes and sizes. They serve as a reliable foundation for constructing trade show booths, while also granting design flexibility, facilitating effortless assembly, disassembly, and transport. Furthermore, aluminum profiles can be seamlessly integrated with other materials like fabric, glass, or acrylic panels, creating trade show booths that are both visually captivating and practical. In summary, owing to their versatility, strength, and user-friendliness, aluminum profiles remain a favored option in the trade show industry.

- Q: This question asks for a method to determine the quantity of aluminum extrusions required for a particular project.

- <p>To calculate the amount of aluminum extrusions needed for a specific project, follow these steps: 1. Determine the dimensions and design of the project to understand where and how aluminum extrusions will be used. 2. Calculate the length of each extrusion piece required based on the project's structure. 3. Multiply the number of pieces by the length of each piece to get the total length of aluminum needed. 4. Consider any additional factors such as waste, tolerances, and potential design changes. 5. Consult with an aluminum supplier or use specialized software for more precise calculations, especially for complex projects. Always account for a margin of error and additional material for contingencies.</p>

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: This question asks for methods to ensure that aluminum profiles used in a construction project adhere to safety standards.

- <p>To ensure that the aluminum profiles used in your building project meet safety standards, you should source materials from reputable suppliers who provide certified products. Check for compliance with relevant standards such as ASTM, ISO, or local building codes. Request material certifications and test reports that confirm the profiles' strength, durability, and resistance to environmental factors. Engage a qualified engineer to review the specifications and design of the aluminum profiles to ensure they meet structural requirements. Conduct regular inspections during construction to verify that the profiles are installed correctly and are free from defects. Finally, maintain proper documentation of all materials and inspections to provide a traceable record of compliance with safety standards.</p>

- Q: This question asks about the various types of aluminum profiles that are utilized in flooring systems, seeking to understand their specific applications and characteristics.

- <p>Aluminum profiles for flooring systems are designed for specific purposes and come in various types, including: 1. T-profiles, which are used as support beams for raised access floors; 2. L-profiles, often used for edge trims and transitions; 3. H-profiles, serving as main beams in the flooring structure; 4. U-channels, used for cover strips and edge protection; 5. C-profiles, which can be used for cable management within the floor void; 6. Z-profiles, suitable for joint covers and transitions. These profiles are chosen based on the load-bearing requirements, aesthetic considerations, and specific structural needs of the flooring system.</p>

- Q: Can aluminum profiles be used in the construction industry?

- The construction industry can utilize aluminum profiles, which possess qualities such as being lightweight, durable, and resistant to corrosion. These attributes make them suitable for a wide range of construction applications. Aluminum profiles are commonly employed in the production of windows, doors, curtain walls, and structural framing systems. They offer an excellent strength-to-weight ratio, enabling the creation of large and intricate structures without excessive weight. Furthermore, they are easily molded into various shapes and sizes, providing flexibility in design and construction. The thermal conductivity of aluminum profiles is also advantageous, as it allows for efficient insulation and energy conservation. All in all, due to their versatility, durability, and aesthetic appeal, aluminum profiles are a favored choice in the construction industry.

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have relatively poor noise insulation properties compared to other materials commonly used for soundproofing, such as wood or PVC. Aluminum is a lightweight and thin material, which allows sound waves to easily pass through it. It does not provide a significant barrier to block or absorb sound, resulting in minimal noise reduction. However, certain aluminum profiles can be designed with additional features to enhance their noise insulation capabilities, such as incorporating insulating materials or using thicker profiles. These modifications can improve the soundproofing performance to some extent, but it still may not be as effective as other materials specifically designed for noise insulation.

Send your message to us

Custom Aluminum Profiles for Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords