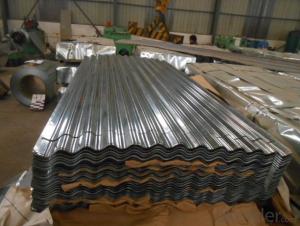

Corrugated Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Hot Dipped Galvanized Steel Sheet

Description:

Corrugated sheet is a high strength and durable steel, mostly used for a architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings.

Pressing steel panel can be freely incised, it can satisfy the especially designing demands. It apply on convenient construction, and anti-seismic performance, fire proof, waterproof, free of maintenance, ect.

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product Specification:

Thickness tolerance: (+/-0.01mm)

Zinc coating: 50-180g/m2

Standard:jis g 3302, sgch

Package: 2- 3 ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to serve as a form of material storage and transportation for various industries. These coils are typically made by winding steel strips into a circular shape, providing a compact and efficient way to store large quantities of steel. Steel coils are used in numerous applications, such as manufacturing, construction, automotive, and appliance industries, where they can be easily transported, processed, and formed into the desired shape for different products.

- Q: What are the factors affecting the lifespan of steel coils?

- The lifespan of steel coils can be influenced by various factors. To begin with, the quality of the steel utilized in the coil manufacturing process plays a significant role. Steel of high quality, possessing appropriate composition and metallurgical properties, tends to have a longer lifespan in comparison to lower-quality steel. Moreover, the environment in which the steel coils are stored and utilized also impacts their longevity. Exposure to extreme temperatures, humidity, and corrosive substances can result in the degradation and corrosion of the coils, ultimately reducing their lifespan. To prolong the lifespan of the coils, it is crucial to maintain proper storage conditions, including controlled temperature and humidity levels. Additionally, the handling and transportation of steel coils can have an effect on their lifespan. Mishandling, such as dropping or improper loading and unloading, can lead to physical damage, causing premature failure of the coils. Similarly, rough transportation conditions characterized by excessive vibration or impact can contribute to coil deterioration and a reduction in their lifespan. Furthermore, the maintenance and care of the steel coils also play a role in determining their lifespan. Regular inspections, cleaning, and maintenance practices aid in the identification and resolution of potential issues before they escalate into major problems. Moreover, applying protective coatings or treatments to the coils can prevent corrosion and extend their lifespan. In summary, the lifespan of steel coils is influenced by a combination of factors, including steel quality, storage conditions, handling and transportation, and maintenance practices. It is essential to consider these factors and implement appropriate measures to ensure the longevity of the coils.

- Q: How are steel coils inspected for impact resistance using impact testers?

- Steel coils are inspected for impact resistance using impact testers by subjecting them to controlled impacts of varying force and measuring the resulting deformation or damage. The testers typically consist of a pendulum or a falling weight that strikes the surface of the coil, simulating real-life impacts. The force and velocity of the impact can be adjusted as per the testing requirements. The extent of deformation or damage is then visually assessed or measured using specialized equipment, providing valuable information about the coil's ability to withstand impacts and potential performance in real-world applications.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- steel wool = iron fibers and rusts easily in air iron + Oxygen BUT the blue soap protects the iron at first. that needs to be cleaned off. damp surfaces speed the rusting but compeletly underwater there is not much O2, ther eis some temperature has an effect. the rusting depends ofn the area of the fibers which does NOT change when you cut th epad in smaller pieces. a good beginners experiment In old times thye thought the rusted material would lose weight becasuse it was not solid iron any more careful experiments showed it gained weight and lead to and understanding of chemistry

- Q: What are the different methods of galvanizing steel coils?

- There are several methods of galvanizing steel coils, including hot-dip galvanizing, electro-galvanizing, and continuous galvanizing.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets as they serve as the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and welding to shape and form the brackets. The high strength and durability of steel coils ensure that the brackets maintain their structural integrity and can withstand heavy loads or harsh conditions.

- Q: How are steel coils used in the manufacturing of food processing equipment?

- Steel coils are used in the manufacturing of food processing equipment as they provide strength, durability, and resistance to high temperatures. These coils are often used to construct the frames, structures, and components of food processing machinery, ensuring stability and reliability during the manufacturing process.

- Q: What are the different methods of edge wave correction for steel coils?

- Steel coils often experience edge waves, which are deformations along the edges. To address this issue, various methods are commonly employed. One frequently used technique is edge wave flattening. This involves applying pressure to the coil's edges using hydraulic or mechanical devices. By doing so, any waves or deformations are effectively flattened out. Edge wave flattening can be performed during the coil processing stage or as a separate step after production. Another approach is edge trimming, where the coil's edges are trimmed or cut to remove waves or deformations. Mechanical shearing or laser cutting technology can be utilized for this purpose. Edge trimming not only corrects edge waves but also ensures straight and smooth edges. Tension leveling is another popular method. It involves subjecting the coil to tension forces, which stretch and flatten any waves or deformations. Tension leveling is typically performed during the processing stage and is effective in correcting both edge waves and other surface defects. Roll leveling is also effective for correcting edge waves. This method utilizes a set of rolls to gradually apply pressure to the coil, resulting in the flattening of waves or deformations. Roll leveling is a versatile technique that can address various types of coil defects, including edge waves. Furthermore, advancements in technology have led to the development of automated edge wave correction systems. These systems employ sensors and computer algorithms to detect and correct edge waves in real-time during the coil processing stage. This method ensures precise and consistent correction, reducing the need for manual intervention and improving overall efficiency. In summary, the methods for correcting edge waves in steel coils include edge wave flattening, edge trimming, tension leveling, roll leveling, and automated correction systems. Each method offers unique advantages and can be chosen based on the specific requirements and constraints of the coil processing operation.

- Q: How are steel coils inspected?

- Steel coils are inspected using various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify any defects, irregularities, or damages in the steel coils, ensuring their quality and suitability for further processing or use.

- Q: What are the applications of steel coils in automotive manufacturing?

- Steel coils have various applications in automotive manufacturing. They are used primarily for the production of car bodies, as well as for other components such as doors, hoods, fenders, and trunk lids. Steel coils provide high strength, durability, and formability, making them suitable for creating robust and safe vehicles. Additionally, they offer excellent resistance to corrosion and can be easily molded into complex shapes, ensuring the desired design aesthetics and functionality.

Send your message to us

Corrugated Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords