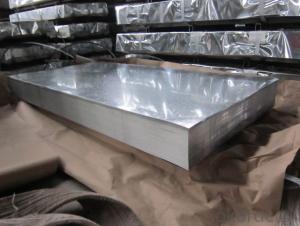

HOT-DIPPED GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: What are the different types of steel alloys used in coil manufacturing?

- There are several different types of steel alloys used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Carbon steel is the most commonly used alloy, known for its high strength and durability. Stainless steel is used for its corrosion resistance and aesthetic appeal. HSLA steel offers a combination of strength, formability, and weldability, making it suitable for various applications in coil manufacturing.

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery primarily for the fabrication of structural components and parts such as frames, chassis, axles, and brackets. The high strength and durability of steel make it an ideal material for these applications, ensuring the machinery can withstand the harsh conditions and heavy loads typically encountered in agricultural operations. Steel coils are processed and formed into the required shapes and sizes to create sturdy and reliable components that contribute to the overall performance and longevity of agricultural machinery.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This coating process involves applying a thin layer of holographic material onto the surface of the steel coils, creating a visually striking and distinctive holographic pattern.

- Q: What are the challenges in coil blanking for high-strength steel?

- Coil blanking for high-strength steel presents several hurdles due to the unique properties of this material. One of the main obstacles lies in the steel's high tensile strength, which makes cutting and blanking more difficult when compared to traditional steel grades. High-strength steel is typically harder and less malleable, resulting in heightened tool wear and greater cutting forces. Therefore, specialized cutting tools capable of enduring these extreme conditions are necessary. Additionally, the augmented cutting forces can cause increased vibrations, potentially impacting the accuracy and quality of the blanks. Another challenge arises from the spring-back effect displayed by high-strength steel after it is cut. This means that the material tends to return to its original shape, creating difficulties in achieving precise dimensions and tolerances in the blanks. Consequently, careful consideration and adjustment of the cutting parameters are required to minimize the spring-back effect. Furthermore, high-strength steel often contains a higher carbon content, leading to increased work hardening during the blanking process. As a result, the material becomes even harder and more brittle, making it more susceptible to cracks and fractures. To overcome this challenge, proper lubrication and cooling techniques are crucial in reducing heat buildup and minimizing the risk of cracking. Additionally, the heightened strength of the steel can also impact overall production efficiency. The increased cutting forces and tool wear may necessitate a reduction in cutting speeds, resulting in longer processing times. This can affect the productivity and throughput of the coil blanking process, requiring meticulous optimization and planning. In conclusion, the challenges involved in coil blanking for high-strength steel encompass increased cutting forces, tool wear, the spring-back effect, work hardening, and reduced production efficiency. Overcoming these challenges necessitates the use of specialized cutting tools, precise cutting parameters, proper lubrication and cooling techniques, and meticulous optimization of the production process.

- Q: What are the different types of coatings applied to steel coils?

- There are various types of coatings that can be applied to steel coils, each with its own specific purpose and benefits. 1. Galvanized Coating: This is one of the most common types of coatings applied to steel coils. It involves the application of a layer of zinc to the steel surface. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor applications where the steel may be exposed to moisture or harsh environmental conditions. 2. Galvalume Coating: Similar to galvanized coating, galvalume coating also involves the application of a layer of zinc to the steel surface. However, it also includes a small amount of aluminum, which enhances the corrosion resistance and provides better heat reflectivity. Galvalume coatings are often used in roofing and cladding applications. 3. Pre-painted Coating: Pre-painted coatings involve the application of a layer of paint or primer to the steel surface. This type of coating allows for customization in terms of color and finish. Pre-painted coatings not only enhance the aesthetics of the steel but also provide additional protection against corrosion and weathering. 4. Organic Coating: Organic coatings are typically applied as a topcoat over a galvanized or galvalume coating. They are made of various resins, such as polyester, epoxy, or polyurethane, which provide additional protection against corrosion, abrasion, and chemicals. Organic coatings are commonly used in applications where both aesthetics and durability are important, such as in the automotive industry. 5. Metallic Coating: Metallic coatings, such as aluminum or zinc, are applied to steel coils using a process called hot-dip coating. These coatings provide excellent corrosion resistance and are commonly used in applications where the steel is exposed to high temperatures or corrosive environments. 6. Chromate Conversion Coating: Chromate conversion coatings are applied to steel coils primarily for their corrosion resistance properties. They are commonly used in electrical applications to protect against galvanic corrosion and improve conductivity. Overall, the type of coating applied to steel coils depends on the specific requirements of the application, including the desired level of corrosion resistance, aesthetics, and environmental factors.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process called galvanization. In this process, the steel coils are submerged in a bath of molten zinc, creating a protective zinc coating on the surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus inhibiting corrosion.

- Q: Steel resist tension. Then why we provide steel in compression zone ?

- There are several reasons to add compression steel. Keep in mind, supported steel (meaning it can't buckle) resists compression as well. Compression steel helps reduce long term deflections. Concrete creeps under sustained loads. Steel lessens the compression, meaning less sustained compressive stress to cause creep deflection. It makes members more ductile. Since the steel takes some of the compressive stress, the compression block depth is reduced, increasing the strain in the tension steel at failure, resulting in more ductile behavior (the moment at first yield remains largely the same with compression steel added, but the increase in capacity after yield is significant). Compression steel insures that the tension steel yields before the concrete crushes, meaning it helps change the failure mode to tension controlled. It makes beams easier to construct. With bars in the top and bottom, you have longitudinal reinforcement in all 4 corners of the shear stirrups to keep them in place when pouring the concrete. Also, for continuous members, its often easier to run your negative moment steel the full length of the beam rather than trying to cut it off in the positive moment regions. Serviceability concerns. You're going to end up putting steel in that region anyway to for temperature and shrinkage.

- Q: Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Cold Steel is a Ventura, California-based marketer of knives, swords and other edged weapons and tools. Cold Steel was founded in 1980 by company president, Lynn C. Thompson.[1] Its products are manufactured in various countries including Japan, Taiwan, China and India.[2] Cold Steel's products include fixed blade knives, folding knives, swords, machetes, tomahawks, kukris, blowguns, walking sticks, and other martial arts related items.[1] Many of their knives are also made using VG-1 Stainless Steel,4116 Krupp Stainless Steel, 1055 Carbon Steel, SK-5 High Carbon Steel, and AUS 8A Stainless Steel.[3]

- Q: Which of the two are better for exhaust manifolds, im guessing the stainless steel right?

- I would go with the stainless steel. I know that there was recently a study done that said that the non-stick material is slowly leaking the non-stick coating into your food. There is a problem with the copper and other metal pans as well. Slowly poisoning you throughout the years. As far as the cast iron, I am not totally sure that there are any problems with those. I haven't heard anything about them that is. I do know that cast iron gets hotter and cooks faster than the other metals. I hope I was able to help. Good luck.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery as they are a key component in the manufacturing of various parts. These coils are used to create durable and strong components such as frames, chassis, and structural supports, which are essential for the heavy-duty requirements of agricultural machinery. The steel coils are shaped, cut, and welded to create these components, ensuring the machinery can withstand the demanding conditions of farming operations.

Send your message to us

HOT-DIPPED GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords