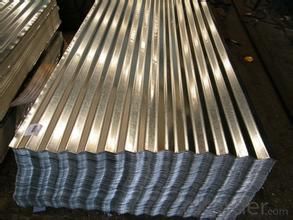

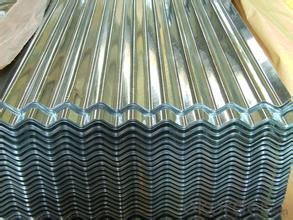

Galvanized Corrugated Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Size

corrugated steel sheet

thickness:0.14-0.8mm

full hard quanlity

reasonable corrugated metal price

ISO:9001:2000

Introduction

Corrugated Steel Sheet is made of quality galvanized steel sheet with automatic press-forming process. It features on light weight, easy installation, fire proof, water proof, long lift-span, etc...

Specifications

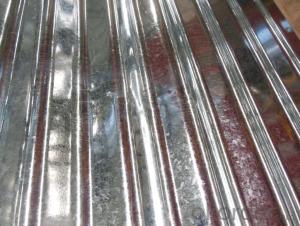

Classification Coating Product Characteristics

Hot dip galvanizing

Zinc coated by hot dip galvanizing; Light coated products have good weldability and formability; Usable from general

processing to deep drawing according to application; Heavy coated products have superior corrosion resistance; Wide

application are possible by selecting spangle or a post treatment.

Applications

Galvanized Corrugated Steel Sheets are used in construction of warehouses, industrial sheds, military establishments,

etc. It is used as roofing material in many buildings, railway stations, waiting zones etc. Thick zinc coating and corrugated

channels makes it water resistant and thus very useful in construction and temporalty establishments.

Our Range of Products

Our wide range of roofing products consists of Trapezoidal Profile, Mandarin Tile, Wall Cladding Corrugation Profile,

and variety of accessories like Flashings, Ridges, Gutters, etc.

- Q: Are steel sheets suitable for railway infrastructure?

- Yes, steel sheets are suitable for railway infrastructure due to their high strength, durability, and resistance to wear and tear. Steel sheets are often used for railway track components such as rails, sleepers, and bridges, as they can withstand heavy loads and provide stability to the railway system. Additionally, steel sheets can be easily fabricated and maintained, making them an ideal choice for railway construction projects.

- Q: Can steel sheets be formed into cylinders or tubes?

- Yes, steel sheets can be formed into cylinders or tubes through a process called roll forming or tube forming.

- Q: How do steel sheets perform in terms of electrical resistance?

- Steel sheets are generally poor conductors of electricity due to their high electrical resistance.

- Q: Are steel sheets resistant to seismic activities?

- Steel sheets can provide some level of resistance to seismic activities due to their strength and flexibility. However, their seismic resistance depends on various factors such as the thickness and quality of the sheets, the building design, and the overall structural system. Proper engineering and construction techniques, including the use of appropriate reinforcement and connections, are crucial to ensure the steel sheets effectively withstand seismic forces.

- Q: What is the difference between a galvanized and aluminum steel sheet?

- To protect carbon steel from corrosion, a layer of zinc is applied to create a galvanized steel sheet. This process, called galvanization, involves immersing the steel in molten zinc, which forms a protective coating on the surface. Galvanized steel sheets are highly durable and act as a barrier against moisture, chemicals, and other corrosive elements. They find wide use in construction, automotive, and industrial sectors. Contrarily, aluminum steel sheets are produced from lightweight and corrosion-resistant aluminum. Rolled from aluminum ingots, these sheets come in varying thicknesses. Even without additional coatings or treatments, aluminum sheets offer exceptional resistance to corrosion. They are commonly employed in aerospace, transportation, and architectural applications. When it comes to differences, the key distinction between galvanized and aluminum steel sheets lies in their composition and protective properties. Galvanized steel sheets possess a zinc coating, which provides superior corrosion resistance compared to plain carbon steel. This makes them more suitable for outdoor and high-moisture environments. Moreover, galvanized steel sheets can be easily welded and painted, allowing for greater customization. In contrast, aluminum steel sheets have inherent corrosion resistance due to the presence of aluminum. They are lighter in weight than galvanized steel sheets, making them a preferred choice for applications that prioritize weight reduction. Aluminum sheets also exhibit better thermal conductivity and reflectivity properties, making them ideal for applications that involve heat dissipation or insulation. To summarize, galvanized steel sheets are carbon steel sheets protected by a layer of zinc to enhance corrosion resistance, while aluminum steel sheets are made from aluminum and offer inherent resistance to corrosion. The choice between galvanized and aluminum steel sheets depends on specific application requirements, such as the level of corrosion protection needed, weight considerations, and desired thermal properties.

- Q: How are steel sheets measured?

- Steel sheets are typically measured by their thickness, width, and length. The thickness is measured in gauges or millimeters, while the width and length are measured in inches or feet.

- Q: Are steel sheets suitable for food processing applications?

- Yes, steel sheets are suitable for food processing applications. Steel is a durable and hygienic material that can withstand high temperatures, corrosion, and impact. It is commonly used in the food industry for equipment such as food preparation surfaces, storage containers, and processing machinery.

- Q: What is AO steel plate?

- It is better to meet the anatomical angle and bone surface in steel plate and Futie professional medical professional operation, to fracture the bones to firm, stable and maximum support.

- Q: How thick are steel sheets available?

- Steel sheets are available in a wide range of thicknesses, depending on the specific requirements of the application. Common thicknesses of steel sheets range from 0.5mm (or 0.020 inches) to several inches thick. The thickness of steel sheets is typically measured in gauge, with lower gauge numbers representing thicker sheets. However, it is important to note that the availability of steel sheets in specific thicknesses may vary depending on the supplier and the type of steel being used.

- Q: What is the weight of a typical steel sheet?

- The weight of a typical steel sheet can vary depending on its dimensions and thickness. However, to provide a general estimate, a standard 4' x 8' steel sheet, commonly used in construction and manufacturing, weighs around 80 to 100 pounds (36 to 45 kilograms). It is important to note that this weight can be higher or lower depending on the specific type of steel and its gauge or thickness.

Send your message to us

Galvanized Corrugated Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords