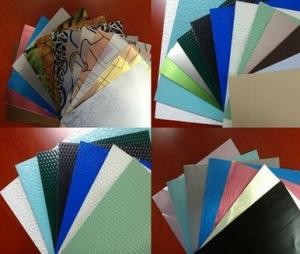

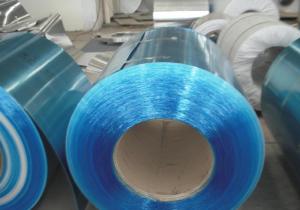

Alloy 1100 3003 3105 5052 Color Coated Aluminum Sheets /Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

COLOR COATED ALUMINUM COIL

Product | Aluminium Coil | ||

Alloy | 1100, 1050, 1060, 3003, 3005, 3105, 8011 etc. | Temper | H12.H14.H16.H18.H22. H24.H26.H32.H34.H36. H38.etc. |

Thickness | 0.02-3.0mm | Width | 50-1500mm |

Coil Weight | 1.5-4MT/Coil | Colors | As per RAL color chart |

Package | Standard export package | ||

Remarks | The Special Dimensions Can Be Produced According to your Specification. | ||

Company Information

CNBM was established in 2005. It is one of the biggest manufacturers of color coated aluminum coil, embossed aluminum coil and aluminum ceiling. Our company has got ISO9001:2008 and SONCAP certifications in 2013. We have 4 color coating lines, 2 slitter lines and 2 embossing lines. And our coating lines are high-speed automatic production line from Germany. Production capacity reaches 36000MT per year.

Our products are widely used in the field of aluminum composite panel, aluminum roofing, aluminum ceiling, aluminum curtain wall, roller shutter doors, aluminum can, aluminum cap rain-gutter and other indoor, outdoor decoration.

Also, we have good cooperation with some famous suppliers, such as PPG, Nippon, Chinalco, Southwest Aluminum etc. Our staff are stilled, especially our engineers, they have rich experience in color coating area for more than 10 years. With high quality, very competitive price, precision equipment and famous brand raw material, our products are very popular both in domestic and abroad market, such as USA, Brazil, Vietnam, Russia, UAE, Nigeria and all over the world.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be and are commonly used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, which protect the food from light, oxygen, moisture, and other external factors that can spoil or contaminate it. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for various types of food packaging, such as foil wraps, containers, trays, and pouches. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for food packaging.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is generally considered to be excellent. Aluminum is a highly malleable metal, meaning it can be easily shaped or formed into various designs without cracking or breaking. This characteristic makes aluminum sheets highly desirable for a wide range of applications, including automotive body panels, aircraft components, and household appliances. Additionally, aluminum has good ductility, which allows it to be stretched and bent without losing its structural integrity. However, it is important to note that the formability of aluminum sheets can vary depending on the alloy composition, thickness, and processing conditions. Therefore, it is essential to consider these factors when choosing the appropriate aluminum sheet for a specific application.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets possess remarkable formability, renowned for their capability to be effortlessly molded and contoured into intricate configurations without encountering any cracks or fractures. The exceptional ductility and malleability of aluminum enable its transformation into diverse shapes, curves, and angles with relative simplicity. This inherent formability renders aluminum sheets highly adaptable for utilization in an array of applications, including automotive body panels, aircraft components, and architectural structures. Moreover, aluminum sheets exhibit commendable resistance to corrosion, further augmenting their performance in various environmental conditions. All in all, aluminum sheets amalgamate formability, strength, and durability, rendering them a favored choice across numerous industries.

- Q: What is the typical electrical conductivity of aluminum sheets?

- The typical electrical conductivity of aluminum sheets is around 35.0 to 45.0 MS/m (mega siemens per meter) or 35,000 to 45,000 S/m (siemens per meter). Aluminum is known for its excellent electrical conductivity, which is approximately 61% of the conductivity of copper. This makes aluminum a popular choice for various electrical applications, such as wiring, power transmission lines, electrical busbars, and electrical equipment components. The conductivity of aluminum allows for efficient and reliable flow of electric current, making it a valuable material in the electrical industry.

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging due to their lightweight, corrosion-resistant, and recyclable properties.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Kitchen backsplashes can indeed utilize aluminum sheets. Aluminum, a versatile and durable material, finds common use in various applications, including kitchen backsplashes. It boasts several advantages, such as its lightweight nature, resistance to corrosion, and ease of cleaning. Aluminum sheets are also easily cut and installed, making them a favored choice for contemporary kitchen designs. Moreover, they come in a wide array of finishes and colors, allowing homeowners to discover a style that complements their kitchen décor. In conclusion, aluminum sheets serve as an exceptional option for kitchen backsplashes, thanks to their practicality, aesthetic appeal, and ability to withstand the demands of a bustling kitchen environment.

Send your message to us

Alloy 1100 3003 3105 5052 Color Coated Aluminum Sheets /Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords