Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

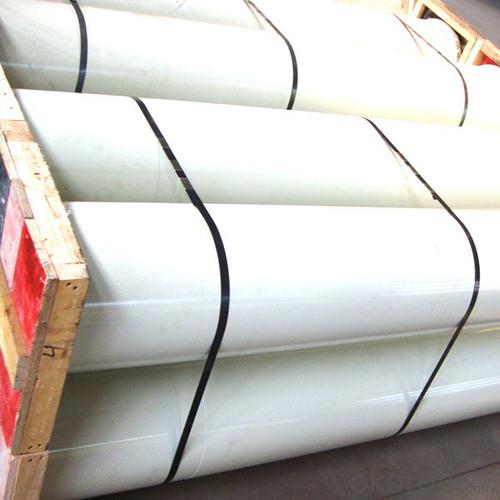

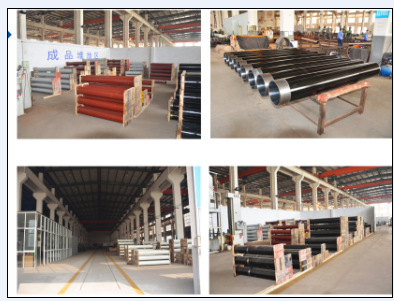

TheConcrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN205*2284 can only be used in Zoomlion concrete pumps construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: ZOOMLION

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN205*2284 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN205*2284 ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce Cylinders DN205*2284 according to customers request?

A4: Yes, we can produce Cylinders DN205*2284 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: Are there any special tools required for replacing concrete pump spare parts?

- Special tools are necessary for replacing concrete pump spare parts. The required tools differ based on the specific part being replaced. However, some commonly used tools include wrenches, sockets, hydraulic jacks, cranes or hoists, and torque wrenches. Certain parts may also necessitate specialized tools like concrete saws, chisels, or drills to remove old parts or prepare surfaces for installation. To ensure proper replacement of concrete pump spare parts, it is crucial to refer to the manufacturer's guidelines or seek professional advice.

- Q: What is the function of a concrete pump hydraulic filter?

- The function of a concrete pump hydraulic filter is to remove contaminants and impurities from the hydraulic fluid that is responsible for operating the pump. The hydraulic filter is designed to capture particles such as dirt, debris, and metal fragments that may be present in the hydraulic system. By removing these contaminants, the filter ensures that the hydraulic fluid remains clean and free from any potential damage-causing particles. This helps to maintain the overall performance and longevity of the concrete pump by preventing clogs, wear and tear, and potential damage to the pump's hydraulic components. Additionally, a clean hydraulic system reduces the risk of hydraulic fluid leakage, which can lead to costly repairs and downtime. Therefore, the concrete pump hydraulic filter plays a critical role in ensuring the efficiency, reliability, and durability of the pump's hydraulic system.

- Q: Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Yes, spare parts for concrete pump hydraulic cylinders and valves are generally available. It is recommended to contact the manufacturer or a reputable supplier to inquire about the specific parts you need for your concrete pump.

- Q: How can you determine when a concrete pump hose needs to be replaced?

- There are several indicators that can help determine when a concrete pump hose needs to be replaced: 1. Visual inspection: Regularly inspect the hose for any signs of wear and tear. Look for cracks, cuts, abrasions, or bulges on the surface. If you notice any significant damage, it is a clear indication that the hose needs to be replaced. 2. Leaks: Check for any leaks in the hose. If you notice any fluid leaking from the hose, it can be a sign of deterioration or damage. Even small leaks should not be ignored as they can compromise the efficiency and safety of the concrete pumping process. 3. Reduced performance: Pay attention to any changes in the pump's performance. If you observe a decrease in the pumping pressure or flow rate, it may be due to a worn-out hose. The hose may have become stretched or worn internally, reducing its effectiveness. 4. Age and usage: Consider the age of the hose and the frequency of its usage. Over time, concrete pump hoses can deteriorate due to exposure to chemicals, weather conditions, and the constant pressure they are subjected to during operation. If the hose is older or has been used extensively, it may be nearing the end of its lifespan. 5. Manufacturer's recommendations: Consult the manufacturer's recommendations regarding the lifespan or replacement intervals for the concrete pump hose. Manufacturers often provide guidelines on when hoses should be replaced based on their specific materials and construction. Ultimately, it is crucial to prioritize safety and reliability when determining whether to replace a concrete pump hose. If there are any doubts about the integrity of the hose, it is best to err on the side of caution and replace it to avoid potential accidents or disruptions in the concrete pumping process.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: How does a concrete pump piston work?

- By creating a back-and-forth movement, the concrete pump piston propels the concrete through the pump and into the desired location. The piston is a cylindrical part that fits snugly inside a cylinder and is connected to a rod, which is linked to a hydraulic system. When the hydraulic system is activated, it propels the rod forward, thereby causing the piston to move in the same direction. As the piston advances, it creates a vacuum behind it, which draws the concrete into the cylinder through an inlet valve. Once the piston reaches the end of its forward stroke, the hydraulic system changes its direction, retracting the rod and causing the piston to move backward. Consequently, this action closes the inlet valve and opens an outlet valve, enabling the concrete to be forced out of the cylinder and into the delivery line. The reciprocating motion of the piston, combined with the alternating opening and closing of the inlet and outlet valves, facilitates a continuous flow of concrete through the pump. This process is rapidly repeated, ensuring efficient and consistent pumping of concrete to the desired location.

- Q: What is the function of a concrete pump control box?

- A concrete pump control box is an essential component of a concrete pump system. Its function is to control and manage the operation of the concrete pump, ensuring a safe and efficient pumping process. The control box allows the operator to start, stop, and adjust the pumping speed of the concrete pump. It typically contains various control switches, knobs, and buttons that are used to control different aspects of the pumping process. One of the main functions of the control box is to monitor the pressure and flow of the concrete being pumped. This information is crucial in ensuring that the concrete is being pumped at the desired rate and consistency. The control box also alerts the operator if there are any abnormalities or issues with the pumping system, such as clogs or blockages. Additionally, the control box may have features like emergency stop buttons and safety interlocks to ensure the safety of both the operator and the equipment. It may also include indicators and alarms to provide visual and audible cues about the status of the pump and any potential issues that may arise. In summary, the function of a concrete pump control box is to provide the operator with the necessary controls and information to safely and efficiently operate the concrete pump. It ensures proper monitoring, control, and safety of the pumping process, ultimately leading to successful concrete placement.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- The pumping efficiency can be significantly affected in various ways by a piston that is damaged. To begin with, reduced pumping capacity can result from decreased power and force exerted by the pump due to a damaged piston. The piston's responsibility is to generate the necessary pressure for pushing the concrete mixture through the pumping system. If it is damaged, it may fail to generate adequate pressure, leading to slower and less efficient pumping. In addition, leaks can occur within the pump system due to a damaged piston. The piston plays a critical role in sealing the concrete and preventing it from leaking back into the hopper. If it is damaged or worn out, a tight seal may not be created, resulting in leakage. This not only leads to material loss but also reduces pumping efficiency as the pump has to compensate for the loss by working harder. Moreover, blockages and clogs can be caused by a damaged piston in the pumping system. The movement of the piston creates suction, which pulls the concrete mixture into the pump. If the piston is damaged, it may not create sufficient suction, causing the mixture to flow unevenly or get stuck in the system. This can cause delays and interruptions in the pumping process, ultimately reducing overall efficiency. In conclusion, the pumping efficiency can be negatively impacted by a damaged concrete pump piston through reduced power and force, leaks, and blockages. It is crucial to regularly maintain and promptly repair or replace damaged pistons to ensure optimal pumping performance and efficiency.

- Q: What are the different types of concrete pump hoses?

- There are generally two types of concrete pump hoses: steel-reinforced hoses and fabric-reinforced hoses. Steel-reinforced hoses are stronger and more durable, suitable for high-pressure applications and long-distance pumping. Fabric-reinforced hoses are lightweight and flexible, ideal for smaller projects and shorter pumping distances.

- Q: Can I get spare parts for concrete pump hoppers and agitators?

- Indeed, one can acquire spare parts for concrete pump hoppers and agitators. Numerous concrete pump and equipment manufacturers and suppliers furnish spare parts for their merchandise. To ascertain the accessibility and cost of spare parts, one may reach out to the manufacturer or supplier of their particular concrete pump hopper or agitator. Furthermore, there exist specialized firms that cater to various brands and models of concrete pumps and equipment, offering an extensive array of spare parts readily available for dispatch upon request.

Send your message to us

Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords