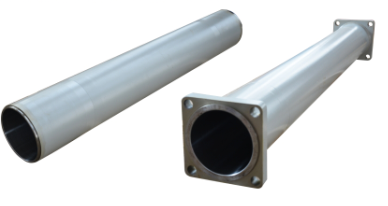

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1587MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

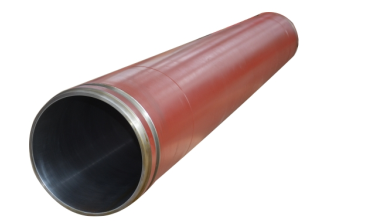

Concrete Pump Delivery Cylinder DN200*1587

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN200*1587

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: How does a concrete pump agitator motor prevent concrete from settling?

- A concrete pump agitator motor prevents concrete from settling by continuously rotating and agitating the mixture, ensuring that the aggregate, cement, and water remain well-mixed. This agitation action prevents the heavier components from sinking and settling at the bottom, maintaining a homogeneous consistency throughout the concrete.

- Q: What are the signs of a damaged concrete pump S valve?

- Some signs of a damaged concrete pump S valve may include leaks, reduced pumping efficiency, irregular or interrupted flow of concrete, excessive wear on the valve components, and difficulty in controlling the concrete output.

- Q: Are there any specific guidelines for the installation of wear plates or cutting rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates and cutting rings in concrete pump spare parts. These guidelines are important to ensure the proper functioning and longevity of the pump. 1. Firstly, it is important to clean the surface where the wear plate and cutting ring will be installed. Any debris, dust, or old material should be removed to ensure a smooth and secure fit. 2. The wear plate and cutting ring should be inspected for any damage or defects before installation. Any parts that are worn out or damaged should be replaced to avoid any potential issues during operation. 3. Apply a thin layer of lubricant or grease to the surface where the wear plate and cutting ring will be installed. This will help with the alignment and ease of installation. 4. Carefully align the wear plate and cutting ring with the designated slots or grooves in the concrete pump. It is crucial to ensure that they are accurately positioned to avoid misalignment or premature wear. 5. Use appropriate tools or equipment to secure the wear plate and cutting ring in place. This may involve tightening bolts, screws, or other fasteners. It is important to follow the manufacturer's instructions and torque specifications to ensure proper installation. 6. After installation, perform a visual inspection to ensure that the wear plate and cutting ring are securely in place and properly aligned. Any signs of misalignment or loose parts should be addressed immediately. 7. Regular maintenance and inspection of the wear plates and cutting rings are essential to identify any signs of wear or damage. It is recommended to follow the manufacturer's recommendations for maintenance intervals and replacement schedules. By following these specific guidelines, you can ensure the proper installation and function of wear plates and cutting rings in concrete pump spare parts, leading to improved performance and extended lifespan of the equipment.

- Q: How to diagnose the blockage in the inlet of concrete pump?

- Make the pump reverse running to destroy the caking, return the concrete to the hopper, stir it again, and then pump it forward

- Q: Are there any specific guidelines for the installation of control valves or solenoids in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control valves or solenoids in concrete pump spare parts. These guidelines typically include proper alignment, mounting, and connection procedures to ensure optimal performance and longevity of the components. Additionally, it is important to follow manufacturer's instructions and recommendations for the specific model of control valve or solenoid being installed.

- Q: How can I extend the lifespan of my concrete pump spare parts?

- There are several ways to extend the lifespan of your concrete pump spare parts. 1. Regular maintenance: Develop a maintenance schedule and stick to it. This includes cleaning, lubricating, and inspecting the parts for any signs of wear or damage. Replace any worn-out parts promptly to prevent further damage. 2. Proper storage: Store your spare parts in a clean and dry environment to prevent rust and corrosion. Keep them away from moisture, extreme temperatures, and direct sunlight. 3. Use quality parts: Invest in high-quality spare parts from reputable manufacturers. These parts are usually more durable and have a longer lifespan compared to cheaper alternatives. 4. Follow manufacturer guidelines: Always follow the manufacturer's guidelines for operating and maintaining your concrete pump. This ensures that you use the spare parts correctly and minimize the risk of premature wear. 5. Train operators: Properly train your operators on the correct usage and handling of the concrete pump and its spare parts. This reduces the chances of accidental damage caused by improper operation. By implementing these practices, you can significantly extend the lifespan of your concrete pump spare parts and maximize their performance and efficiency.

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can significantly affect the pumping efficiency in a variety of ways. Firstly, an accumulator is a device that stores energy in the form of pressurized fluid. It helps regulate the flow of fluid in a hydraulic system and provides additional power when needed. If the accumulator is faulty, it may not be able to store or release fluid properly, leading to an imbalance in the hydraulic system. This imbalance can cause fluctuations in pressure, flow rate, and overall system performance, resulting in reduced pumping efficiency. Secondly, a faulty accumulator can lead to increased wear and tear on the pump. When the accumulator fails to regulate the pressure properly, it can cause the pump to work harder and operate outside its normal operating range. This additional stress on the pump can lead to premature failure, decreased lifespan, and increased maintenance costs. Ultimately, this affects the pumping efficiency as the pump may not be able to deliver the desired flow rate and pressure due to its compromised condition. Furthermore, a faulty accumulator may result in unstable or inconsistent flow rates. As the accumulator is responsible for maintaining a steady flow of fluid, any malfunction can disrupt this flow pattern. This inconsistency in flow can lead to inefficiencies in the pumping system, such as increased energy consumption, reduced output, and inadequate operation of downstream components. Lastly, a faulty accumulator can impact the overall system response time. Accumulators play a crucial role in providing quick response and compensating for sudden changes in demand. If the accumulator fails to function properly, the system may experience delays in responding to load changes, leading to slower operation, reduced productivity, and potential safety hazards. In conclusion, a faulty accumulator can have a detrimental impact on pumping efficiency. It can cause imbalances in the hydraulic system, increase wear on the pump, result in unstable flow rates, and decrease overall system response time. Regular maintenance, inspection, and timely repair or replacement of faulty accumulators are essential to ensure optimal pumping efficiency and prevent potential system failures.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: Can I get spare parts for concrete pump hoppers and agitators?

- Indeed, one can acquire spare parts for concrete pump hoppers and agitators. Numerous concrete pump and equipment manufacturers and suppliers furnish spare parts for their merchandise. To ascertain the accessibility and cost of spare parts, one may reach out to the manufacturer or supplier of their particular concrete pump hopper or agitator. Furthermore, there exist specialized firms that cater to various brands and models of concrete pumps and equipment, offering an extensive array of spare parts readily available for dispatch upon request.

- Q: How can a faulty oil cooler affect the pump's hydraulic system?

- A faulty oil cooler can affect the pump's hydraulic system in several ways. Firstly, the oil cooler is responsible for maintaining the optimal temperature of the hydraulic oil. If the oil cooler is faulty and fails to cool the oil effectively, the hydraulic oil may overheat. This can lead to a decrease in the oil's viscosity, causing it to lose its lubricating properties. As a result, the pump's moving parts may experience increased friction and wear, leading to reduced efficiency and potentially causing damage to the pump itself. Secondly, a faulty oil cooler may result in inadequate cooling of the hydraulic oil, leading to elevated temperatures within the system. High temperatures can cause the oil to oxidize, resulting in the formation of sludge and varnish deposits. These deposits can clog the hydraulic system, including the pump, valves, and other components, impeding their smooth operation and potentially causing them to malfunction. Additionally, a faulty oil cooler may also lead to a decrease in oil flow rate. If the oil cooler is not functioning properly, it may restrict the flow of hydraulic oil, reducing the amount of oil available for the pump's operation. This can result in decreased hydraulic pressure, affecting the pump's performance and potentially leading to issues such as reduced power output or inadequate operation of hydraulic actuators. Overall, a faulty oil cooler can negatively impact the pump's hydraulic system by causing overheating, increased friction and wear, the formation of deposits, and reduced oil flow rate. It is crucial to regularly inspect and maintain the oil cooler to ensure its proper functioning and prevent any potential damage to the hydraulic system.

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1587MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords