PUMPING CYLINDER(ZOOMLION) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1787MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

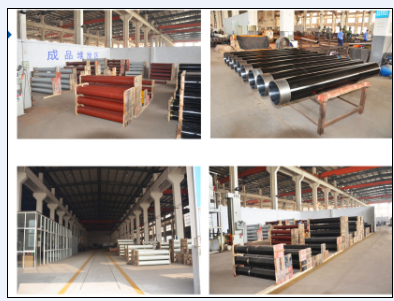

The Concrete Pump Delivery Cylinder DN200*1787 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN200*1787 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN200*1787 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*1787

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN200*1787 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN200*1787 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN200*1787?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN200*1787 according to customers request?

A4: Yes, we can produce Cylinders DN200*1787 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- To minimize downtime during the replacement of concrete pump spare parts, it is crucial to follow a few key steps. First, ensure that you have a comprehensive understanding of the specific spare parts required for your concrete pump. This will help you streamline the ordering process and minimize delays. Additionally, it is essential to schedule regular maintenance and inspections to identify any potential issues beforehand, allowing you to proactively replace parts before they fail. Lastly, work with a reputable supplier who can provide high-quality spare parts promptly, reducing downtime.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Spare parts for both concrete pumps, with or without boom control systems, are generally available. Numerous manufacturers and suppliers offer a diverse selection of spare parts to cater to various pump types. Whether your pump has a boom control system or not, reliable suppliers should have the necessary spare parts in stock. To ensure compatibility and check availability for your specific concrete pump model, it is advisable to directly contact the manufacturer or supplier.

- Q: How much is the pump for a month?

- In the mud, the price is about 25 yuan per square, according to my experience, more than 175000 points per month can pump 7000 yuan, totaling $

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Concrete pump spare parts can be replaced individually, as there is no requirement to replace them as a set. This allows for more cost-effective and efficient maintenance, as only the specific part that needs replacement can be addressed.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- Hopper agitator shafts in a concrete pump should be inspected regularly, ideally during routine maintenance checks, to ensure they are in proper working condition. The frequency of inspections may vary depending on the usage and operating conditions of the concrete pump. However, a general recommendation would be to inspect or replace hopper agitator shafts at least once every 6 to 12 months to prevent any potential issues or malfunctions.

- Q: What are the safety measures to consider while replacing concrete pump spare parts?

- When replacing concrete pump spare parts, there are several important safety measures to consider. Firstly, it is crucial to ensure that the pump is turned off and all power sources are disconnected before beginning any work. Additionally, wearing appropriate personal protective equipment, such as gloves, safety glasses, and steel-toed boots, is essential to protect against potential hazards. It is important to follow the manufacturer's guidelines and instructions for replacing the specific spare part to ensure proper installation and prevent accidents. Lastly, maintaining a clean and organized work area, free from clutter and debris, can help prevent trips and falls while working on the pump.

- Q: Can concrete pump spare parts be tested for performance and quality before installation?

- It is imperative to test concrete pump spare parts for performance and quality before installation. This ensures that they conform to necessary standards and specifications, and aids in detecting any flaws or concerns that might impact their performance or longevity. Testing can be carried out through diverse methods, including physical inspections, functional assessments, or deploying specialized equipment to gauge specific parameters. By conducting pre-installation tests on these spare parts, potential issues can be identified and rectified at an early stage, thereby guaranteeing peak performance and quality.

- Q: How can a malfunctioning control lever affect the pump's operation?

- A malfunctioning control lever can significantly impact the pump's operation. It may cause the pump to operate at incorrect speeds, resulting in inefficient performance or potential damage to the pump. Additionally, a malfunctioning control lever can lead to improper fluid flow control, leading to inconsistent or inaccurate output. Overall, it is crucial to promptly address any issues with the control lever to ensure the pump operates reliably and efficiently.

- Q: How often should hopper vibrators be inspected or replaced in a concrete pump?

- To ensure the proper functioning of hopper vibrators in a concrete pump and prevent any potential problems, it is important to conduct regular inspections. The frequency of these inspections or replacements may vary depending on several factors, such as the intensity of use, operating conditions, and the manufacturer's recommendations. As a general rule, it is recommended to inspect hopper vibrators at least once a year or after every 500-600 hours of operation, whichever comes first. However, if the concrete pump is heavily used or operates in harsh environments, more frequent inspections may be necessary. During the inspection, it is essential to check the hopper vibrators for any signs of wear, damage, or loose connections. Additionally, the vibration intensity and frequency should be assessed to ensure they are within the recommended range. Any issues identified during the inspection should be promptly addressed through repairs or replacements to ensure the hopper vibrators continue to function effectively. Regular inspections and timely replacements of hopper vibrators are crucial for maintaining the efficiency and reliability of a concrete pump. Neglecting these inspections can result in decreased performance, increased downtime, and potentially expensive repairs. Therefore, it is important to adhere to the manufacturer's guidelines and seek professional advice to determine the appropriate frequency for inspections and replacements based on the specific circumstances of your concrete pump.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Certainly, spare parts for concrete pump accessories like remote control systems can be obtained. A variety of spare parts for these products are offered by numerous manufacturers and suppliers of concrete pump accessories. These spare parts encompass various components for remote control systems, including buttons, switches, sensors, batteries, and transmitters. To ensure the availability of spare parts for your particular model of remote control system, it is advisable to directly contact the manufacturer or supplier. They will be equipped to furnish you with the essential information and aid you in procuring the necessary spare parts.

Send your message to us

PUMPING CYLINDER(ZOOMLION) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1787MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords