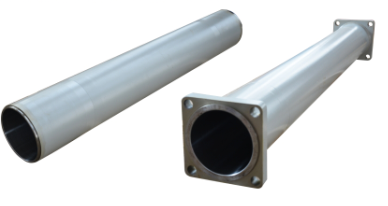

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1862MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*1862

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

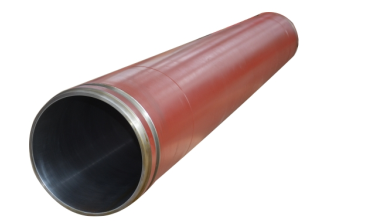

Concrete Pump Delivery Cylinder DN200*1862

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: How can one ensure compatibility between concrete pump spare parts and the pump?

- To ensure compatibility between concrete pump spare parts and the pump, it is essential to follow the manufacturer's guidelines and specifications. This includes sourcing spare parts from authorized dealers or reputable suppliers who specialize in concrete pump equipment. Additionally, maintaining a thorough understanding of the pump's model, make, and technical requirements can help in selecting the correct spare parts. Regular inspection and maintenance of the pump can also help identify any potential issues or parts that may need replacement, ensuring smooth compatibility between the pump and its spare parts.

- Q: How can a faulty boom affect the concrete placement process?

- A faulty boom can significantly affect the concrete placement process. It can lead to uneven distribution of concrete, resulting in inconsistent concrete strength and quality. It may also cause the concrete to be placed in unintended areas or at incorrect heights, affecting the overall structural integrity of the project. Additionally, a faulty boom can pose a safety risk to workers and equipment involved in the concrete placement process.

- Q: What are the different types of concrete pump pistons?

- There are several different types of concrete pump pistons that are commonly used in the construction industry. These include: 1. Single-acting pistons: These pistons have one working side and are used in smaller concrete pumps. They push the concrete out of the cylinder during the forward stroke and rely on gravity to pull the piston back during the return stroke. 2. Double-acting pistons: These pistons have two working sides and are used in larger concrete pumps. They push the concrete out during the forward stroke and pull it back during the return stroke, increasing the efficiency of the pumping process. 3. S-tube pistons: These pistons are shaped like an S and are commonly used in trailer-mounted concrete pumps. They help to control the flow of concrete by directing it through a series of valves and pipes. 4. Rock valve pistons: These pistons are designed specifically for pumping concrete with larger aggregates. They have a rugged design that can handle the more abrasive nature of these types of materials. 5. Gate valve pistons: These pistons use a gate valve system to control the flow of concrete. They are commonly used in high-pressure applications and offer precise control over the amount of concrete being pumped. Overall, the type of concrete pump piston used will depend on the specific requirements of the construction project, including the size of the pump, the type of concrete being pumped, and the desired flow rate and pressure.

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage and maintain the pressure within the pumping system. Concrete pumps are used to transfer liquid concrete from one location to another, typically from a mixer truck to a construction site. These pumps operate under high pressure to ensure the concrete flows smoothly through the pipeline. A concrete pump seal is a vital component that helps maintain the integrity of the pumping system. It is usually made of durable materials such as rubber or polyurethane, designed to withstand the high pressures and abrasive nature of concrete. The seal is located at the connection points between various sections of the pipeline, including the pump, pipeline joints, and hose connections. The primary function of the seal is to prevent concrete from leaking out of the system. Concrete is a viscous material, and any leakage can cause significant problems, such as a decrease in pumping efficiency, wastage of concrete, and potential damage to the surrounding environment. The seal ensures that the pumping system remains leak-free, allowing for efficient and continuous concrete transfer. Additionally, the seal helps maintain the required pressure within the pumping system. Concrete pumps rely on consistent pressure to ensure the concrete is delivered smoothly and evenly. Any pressure loss due to leakage can lead to uneven flow or blockages in the pipeline, affecting the overall performance of the pump. By sealing the connection points, the seal helps maintain the desired pressure, ensuring the concrete is pumped efficiently. Overall, the role of a concrete pump seal is to prevent leakage, maintain pressure, and ensure the smooth and efficient transfer of concrete from the source to the destination. It is an essential component that contributes to the overall effectiveness and reliability of concrete pumping operations.

- Q: Can I get spare parts for concrete pump hopper agitators and vibrators?

- Yes, spare parts for concrete pump hopper agitators and vibrators are generally available. These parts can be sourced from various manufacturers and suppliers specializing in construction equipment and machinery. It is recommended to contact the manufacturer of the concrete pump or the authorized dealer to inquire about the availability and pricing of spare parts for the hopper agitators and vibrators. Additionally, there are also online platforms and marketplaces that offer a wide range of spare parts for construction equipment, including concrete pump components. It is important to provide specific details about the make and model of the concrete pump to ensure compatibility and proper functioning of the spare parts.

- Q: How do I properly maintain and replace hydraulic valves in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic valves in concrete pump spare parts is essential to ensure the smooth operation and longevity of the equipment. Here are some steps to follow: 1. Regular Inspection: Regularly inspect the hydraulic valves for any signs of wear, damage, or leakage. Look for cracks, corrosion, or any other visible defects. It is important to catch any issues early on to prevent further damage. 2. Cleanliness: Keep the hydraulic valves clean to prevent dirt, debris, or contaminants from entering the system. Use a suitable cleaning agent and a lint-free cloth to wipe the valves and remove any buildup. 3. Lubrication: Proper lubrication is crucial for the smooth operation of hydraulic valves. Refer to the manufacturer's guidelines to determine the appropriate lubricant and the recommended schedule for lubrication. Apply the lubricant as per the instructions provided. 4. Replacement: If a hydraulic valve is damaged or worn out beyond repair, it is important to replace it promptly. Identify the correct replacement valve by referring to the equipment's manual or consulting with the manufacturer. Ensure that the replacement valve matches the specifications required for your concrete pump. 5. Professional Assistance: While some maintenance tasks can be done by operators, it is advisable to seek professional assistance for complex maintenance and replacement procedures. Professional technicians have the expertise and knowledge to handle hydraulic valves safely and effectively. 6. Safety Precautions: Always adhere to proper safety protocols when working with hydraulic valves. Remove any sources of pressure and fully depressurize the system before attempting any maintenance or replacement. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from potential hazards. Overall, regular maintenance, timely replacement, and adherence to safety guidelines are essential for properly maintaining and replacing hydraulic valves in concrete pump spare parts. Following these steps will help ensure the reliable and efficient operation of your equipment.

- Q: How long does it take to receive concrete pump spare parts after ordering?

- The time it takes to receive concrete pump spare parts after ordering can vary depending on several factors. It is important to note that the availability of the specific spare parts you need and the location of the supplier can significantly impact the delivery time. In general, if the spare parts are readily available and in stock, you can expect to receive them within a few days to a week. This assumes that the supplier has a streamlined order processing system and prompt shipping arrangements. However, if the spare parts are not in stock, it may take longer to receive them. In such cases, the supplier may need to order the parts from a manufacturer or source them from a distributor. This could add additional lead time to the delivery process, ranging from a few weeks to several months, depending on the availability and sourcing process. It is advisable to check with the supplier or manufacturer before placing the order to get an estimate of the delivery time. Factors like the supplier's location, transportation mode, and any potential customs or logistics delays should also be taken into consideration. To expedite the delivery process, some suppliers may offer expedited shipping options at an additional cost. This can be beneficial if you need the spare parts urgently. Overall, the time it takes to receive concrete pump spare parts after ordering can vary, but being proactive, communicating with the supplier, and planning ahead can help ensure a smoother and quicker delivery process.

- Q: How does a hopper agitator blade ensure smooth concrete flow?

- A hopper agitator blade ensures smooth concrete flow by effectively mixing and breaking up any clumps or air pockets in the concrete mixture. The blade is specifically designed to be placed inside the hopper, where it rotates and agitates the concrete, ensuring that it remains in a uniform and consistent state. As the blade rotates, it helps to disperse any aggregates that may have settled at the bottom of the hopper, preventing them from causing blockages or uneven distribution during the pouring process. This continuous mixing action ensures that the concrete remains well-mixed and free-flowing, allowing for a smooth and even distribution when it is discharged from the hopper. Moreover, the agitator blade also helps to break up any air bubbles that may have formed within the concrete mixture. These air bubbles can weaken the concrete's structural integrity and result in an uneven finish. By agitating the concrete, the blade helps to release trapped air, promoting a more consistent and dense mixture. In summary, a hopper agitator blade ensures smooth concrete flow by effectively mixing the concrete, breaking up any clumps or air pockets, and promoting a consistent and uniform mixture. This ensures that the concrete flows smoothly and evenly during the pouring process, resulting in a high-quality finished product.

- Q: What are the advantages of using genuine spare parts for my concrete pump?

- Using genuine spare parts for your concrete pump comes with several advantages. First and foremost, genuine spare parts are specifically designed and manufactured by the original equipment manufacturer (OEM) for your concrete pump. This means that they are made to fit perfectly and function optimally with your specific model. Using genuine parts ensures compatibility and reduces the risk of compatibility issues or malfunctions that can arise from using aftermarket or counterfeit parts. Secondly, genuine spare parts are made from high-quality materials and undergo rigorous testing to meet strict quality standards. This ensures their durability, reliability, and performance, ultimately resulting in longer service life and reduced downtime for your concrete pump. Genuine parts are designed to withstand the demanding conditions and heavy loads that concrete pumps typically operate under. Moreover, using genuine spare parts helps maintain the warranty and integrity of your concrete pump. Many manufacturers offer warranties that cover the use of genuine parts. By using genuine parts, you can take advantage of the warranty benefits and avoid any potential issues that may arise from using non-genuine parts, which could void the warranty. Additionally, genuine spare parts often come with technical support and expertise from the manufacturer. OEMs have extensive knowledge and experience with their equipment, and their technical support team can provide guidance, advice, and troubleshooting assistance in case any issues arise. This can be extremely beneficial in minimizing downtime and maximizing the efficiency of your concrete pump. Lastly, using genuine spare parts ensures the safety of your equipment and operators. Genuine parts are manufactured to meet strict safety regulations and standards, reducing the risk of accidents or failures that can result from using substandard or counterfeit parts. The safety and well-being of your team should always be a top priority, and using genuine parts helps ensure their protection. In conclusion, the advantages of using genuine spare parts for your concrete pump include compatibility, quality, durability, warranty coverage, technical support, and safety. Investing in genuine parts not only enhances the performance and longevity of your equipment but also provides peace of mind for both you and your team.

- Q: Can concrete pump spare parts be imported from other countries?

- Concrete pump spare parts can indeed be brought in from other countries. Multiple manufacturers and suppliers of these spare parts have a worldwide reach and provide options for international shipping. By importing concrete pump spare parts from other countries, one can gain access to a broader selection of products, competitive prices, and superior components. Nevertheless, it is crucial to take into account factors including import regulations, customs duties, and shipping expenses when bringing in concrete pump spare parts from other countries.

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1862MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords