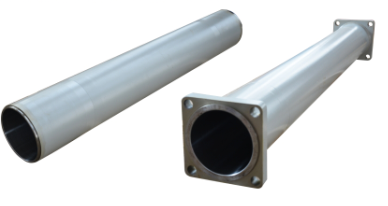

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1187MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*1187

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

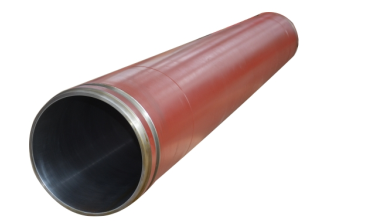

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What is the function of a concrete pump outrigger?

- The function of a concrete pump outrigger is to provide stability and support to the concrete pump while it is in operation. The outrigger extends from the sides of the pump and is used to distribute the weight of the pump and concrete being pumped, preventing it from tipping over or causing any instability.

- Q: What are the different types of concrete pump pistons?

- In the construction industry, various concrete pump pistons are frequently utilized. These encompass the following: 1. Single-acting pistons: Smaller concrete pumps employ these pistons with a single working side. They propel the concrete out of the cylinder during the forward stroke and rely on gravity to retract the piston during the return stroke. 2. Double-acting pistons: Larger concrete pumps utilize these pistons with two working sides. They push the concrete out during the forward stroke and pull it back during the return stroke, thereby enhancing the pumping process's efficiency. 3. S-tube pistons: Trailer-mounted concrete pumps commonly employ these pistons, which are shaped like an S. They assist in regulating the concrete flow by directing it through a series of valves and pipes. 4. Rock valve pistons: These pistons are specifically designed for pumping concrete with larger aggregates. With their sturdy design, they can handle the more abrasive nature of such materials. 5. Gate valve pistons: These pistons employ a gate valve system to manage the concrete flow. They are frequently used in high-pressure applications and provide precise control over the pumped concrete's quantity. In summary, the selection of a concrete pump piston depends on various factors specific to the construction project, including the pump's size, the type of concrete being pumped, and the desired flow rate and pressure.

- Q: Can concrete pump spare parts be painted or coated for increased durability?

- Yes, concrete pump spare parts can be painted or coated for increased durability. Painting or coating the spare parts can help protect them from corrosion, wear, and other forms of damage. By applying a layer of paint or coating, the spare parts can have improved resistance to harsh environmental conditions, chemicals, and moisture. Additionally, certain paints or coatings can offer additional benefits such as heat resistance or non-stick properties, which can further enhance the durability and performance of the spare parts. It is important to use appropriate paints or coatings that are specifically designed for the materials and conditions the spare parts will be exposed to, to ensure optimal adhesion and longevity.

- Q: What is the role of a concrete pump agitator shaft seal?

- The role of a concrete pump agitator shaft seal is to prevent leakage of concrete slurry or other fluids from the agitator shaft, ensuring that the pump operates efficiently and without any loss or contamination of the material being pumped.

- Q: What are the different types of concrete pump control system sensors?

- Concrete pump control systems utilize a variety of sensors to ensure smooth and efficient operation. These sensors are specifically designed to monitor different aspects of the pump's performance and provide real-time feedback to the control system. Common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors measure the concrete pressure during pumping. They are typically installed in the discharge line and are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors measure the rate at which concrete flows through the system. By monitoring the volume of concrete passing through per unit of time, these sensors enable the control system to regulate the pump's speed and output accordingly. 3. Level Sensors: Level sensors monitor the concrete level in the hopper or storage tank. They provide information about the concrete volume to prevent the pump from running dry or becoming overloaded, thus preventing pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors detect the position of moving parts in the pump system, such as the boom or outriggers. They ensure safe operation by providing feedback to the control system and preventing collisions or obstructions. 5. Temperature Sensors: Temperature sensors monitor the concrete mix temperature. They help maintain the desired temperature range during pumping, which is crucial for workability and curing. Optimal concrete temperature contributes to the quality of the final product. In summary, these sensors work in harmony to provide precise feedback to the control system, ensuring efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, these sensors optimize pumping performance and enhance productivity in concrete placement projects.

- Q: What are the key factors to consider when purchasing concrete pump spare parts?

- When purchasing concrete pump spare parts, there are several key factors that need to be considered to ensure you make the right choice. These factors include: 1. Quality: The quality of the spare parts is crucial as it directly impacts the performance and longevity of your concrete pump. Look for high-quality materials and reputable brands to ensure durability and reliability. 2. Compatibility: It is essential to ensure that the spare parts you purchase are compatible with your specific concrete pump model. Check the specifications and consult with experts or the manufacturer to avoid any compatibility issues. 3. Cost-effectiveness: While it is important to consider the price of the spare parts, it should not be the sole determining factor. Look for a balance between cost and quality to ensure that you are getting value for your money in the long run. 4. Supplier reputation: Choose a reliable and reputable supplier who has a track record of providing genuine and high-quality spare parts. Read customer reviews, check their certifications, and consider their experience in the industry. 5. Availability and lead time: Ensure that the spare parts you need are readily available and can be delivered within a reasonable time frame. This is crucial to avoid delays in your construction projects and minimize downtime. 6. Warranty and after-sales support: Check if the spare parts come with a warranty or guarantee. Additionally, consider the availability of after-sales support and technical assistance in case you need any help or guidance during installation or maintenance. 7. Maintenance requirements: Consider the maintenance requirements of the spare parts you are purchasing. Look for components that are easy to install, maintain, and repair, as this can save you time and money in the long run. By considering these key factors, you can make an informed decision and ensure that you purchase the right concrete pump spare parts that meet your specific needs and requirements.

- Q: What is the function of a concrete pump hopper filter?

- Preventing damage and blockages, the concrete pump hopper filter's main function is to keep large debris, like rocks, out of the pump. It acts as a barrier between the hopper and the pump, ensuring that only properly sized aggregate and concrete mixture is pumped through. By reducing the risk of clogs and wear on the equipment, the filter helps maintain the pump's efficiency and longevity. Moreover, it removes unwanted contaminants, thus preserving the quality of the pumped concrete. In construction projects, the concrete pump hopper filter plays a crucial role in safeguarding the pump and ensuring a seamless and uninterrupted flow of concrete.

- Q: How can one determine the correct voltage and current rating for electrical components in concrete pump spare parts?

- To determine the correct voltage and current rating for electrical components in concrete pump spare parts, several factors need to be considered. Firstly, it is essential to consult the manufacturer's specifications and documentation for the concrete pump and its spare parts. These documents usually provide detailed information about the voltage and current requirements for each electrical component. Paying close attention to these guidelines ensures that the components are operated within their designed parameters. Secondly, it is crucial to understand the electrical system and its requirements. This involves analyzing the power supply available at the site where the concrete pump will be used. Factors such as the voltage level (e.g., 110V, 220V, 440V) and frequency (e.g., 50Hz, 60Hz) of the electrical supply need to be taken into account. Additionally, the maximum current capacity of the electrical system must be considered to prevent overload situations. Furthermore, it is advisable to assess the specific application and operating conditions of the concrete pump. Different components may have varying voltage and current requirements depending on their function and the environment in which they are used. For instance, components installed in outdoor areas may require higher voltage ratings to withstand harsh weather conditions. Lastly, seeking professional assistance from qualified electricians or engineers is highly recommended. They possess the expertise and knowledge to accurately determine the voltage and current ratings for electrical components in concrete pump spare parts. Their experience allows them to consider various factors such as safety regulations, compatibility with the existing electrical system, and any specific requirements of the concrete pump manufacturer. By taking into account the manufacturer's specifications, understanding the electrical system, considering the application and operating conditions, and seeking professional advice, one can effectively determine the correct voltage and current rating for electrical components in concrete pump spare parts.

- Q: How often should concrete pump clamps be inspected and replaced?

- Concrete pump clamps should be inspected on a regular basis to ensure they are functioning properly and to identify any signs of wear or damage. The frequency of inspections will depend on various factors such as the frequency of use, the type of concrete being pumped, and the working conditions. In general, it is recommended to inspect concrete pump clamps at least once a month or after every 100 hours of operation, whichever comes first. This will help catch any potential issues early on and prevent them from escalating into major problems. Additionally, it is important to visually inspect the clamps before each use to check for any visible signs of damage or wear. This includes checking for cracks, deformations, or any loose or missing bolts. The lifespan of concrete pump clamps will vary depending on the quality of the clamps, the intensity of use, and the maintenance practices. However, as a general guideline, it is recommended to replace the clamps every 1-2 years or sooner if they show significant signs of wear or damage. Regular inspections and timely replacements of concrete pump clamps are vital to ensure the safety and efficiency of the pumping operations. It is always better to be proactive and address any potential issues promptly to prevent costly repairs or accidents.

- Q: How does a concrete pump hopper grate prevent clogs?

- Preventing clogs in the concrete pump system is a crucial function of the hopper grate. Acting as a filter, it permits only the necessary aggregate size to pass through, while capturing any excess debris or large particles that could cause blockages. Strategically placed openings or grids in the grate catch these unwanted materials. When pouring the concrete mixture into the hopper, the grate serves as a barrier. It allows only the appropriate material size to pass through, while obstructing any larger or undesirable debris. This ensures a smooth flow of concrete through the pump system, preventing any disruptions or jams during construction. Furthermore, the grate is typically constructed from durable materials like steel or high-density polyethylene. These materials are resistant to damage and wear, allowing the grate to withstand the high-pressure environment and continuous operation without deformation. Regular maintenance and cleaning of the hopper grate are also essential to prevent clogs. By inspecting and removing any accumulated debris or build-up on a regular basis, operators can ensure that the grate remains clear and fully functional, thereby preventing potential clogging issues. In conclusion, the concrete pump hopper grate acts as a filter to prevent clogs, allowing only the necessary aggregate size to pass through while capturing larger particles and debris. Its design and durable material ensure a smooth flow of concrete, minimizing the risk of blockages and maintaining construction efficiency.

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1187MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords