Concrete Pump Hardened Pipe DN125 High Endurable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Hardened Pipe DN125 High Endurable

1. Structure of Concrete Pump Hardened Pipe DN125 High Endurable:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Pump Hardened Pipe DN125 High Endurable:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

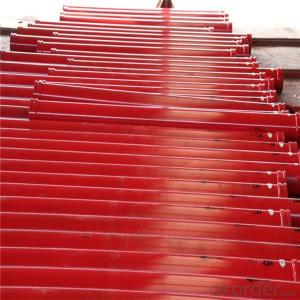

3. Concrete Pump Hardened Pipe DN125 High Endurable Images

4. Concrete Pump Hardened Pipe DN125 High Endurable Specification

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

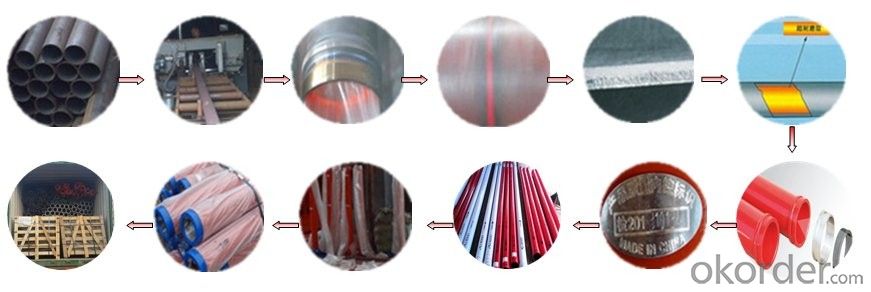

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: How does a concrete pump agitator motor prevent concrete from settling?

- A concrete pump agitator motor prevents concrete from settling by continuously rotating and agitating the mixture, ensuring that the aggregate, cement, and water remain well-mixed. This agitation action prevents the heavier components from sinking and settling at the bottom, maintaining a homogeneous consistency throughout the concrete.

- Q: What are the layout requirements of concrete pump for building engineering?

- When more than one concrete pump or pump truck is pouring at the same time, the selected location should be the closest to each other. It is better to pour the concrete at the same time, so as to avoid retaining the construction joint.

- Q: How does a hydraulic accumulator improve the performance of a concrete pump?

- A hydraulic accumulator improves the performance of a concrete pump by storing excess hydraulic pressure and energy during low-demand periods and releasing it when needed. This allows for a smoother operation, reduced pump pulsation, and improved efficiency in delivering the concrete, resulting in enhanced performance and productivity.

- Q: How can one extend the lifespan of concrete pump spare parts?

- One can extend the lifespan of concrete pump spare parts by ensuring regular maintenance, proper lubrication, and cleaning after each use. Additionally, using high-quality spare parts and avoiding overloading or excessive pressure on the pump can also help prolong their lifespan.

- Q: How often should concrete pump booms be inspected and maintained?

- To ensure the safe and efficient operation of concrete pump booms, it is important to inspect and maintain them regularly. The frequency of these inspections and maintenance tasks will depend on how often and under what conditions the boom is used. Generally, it is recommended to inspect and maintain the boom at least once a month or after every 250 pumping hours, whichever comes first. During these inspections, it is crucial to carefully examine the boom for any signs of wear and tear, damage, or malfunctioning parts. The hydraulic system, including the hoses, cylinders, and valves, should be thoroughly inspected and tested for leaks, blockages, or malfunctions. Additionally, the structural integrity of the boom, such as the main boom, articulation points, and outriggers, should be checked for cracks, deformations, or signs of stress. Regular maintenance of the concrete pump boom should include cleaning and lubricating all movable parts, checking and adjusting the tension of the cables, belts, and chains, and replacing any worn-out or damaged components. It is also important to inspect and test the electrical and control systems to ensure proper functioning. In addition to regular inspections and maintenance, it is crucial to follow the manufacturer's guidelines and recommendations for specific maintenance intervals and procedures. Depending on the level of usage, working conditions, and any changes in performance or operation, it may be necessary to conduct more frequent inspections and maintenance. By conducting regular inspections and maintenance, concrete pump boom owners can reduce the risk of accidents, extend the lifespan of the equipment, and ensure optimal performance. It is always advisable to consult with the manufacturer or a qualified professional to determine the most suitable inspection and maintenance schedule for a specific concrete pump boom.

- Q: What are the signs of a faulty concrete pump control box?

- There are several signs that may indicate a faulty concrete pump control box. These signs can vary depending on the specific issue, but some common signs include: 1. Unresponsive controls: One of the most obvious signs of a faulty control box is when the controls become unresponsive or fail to function properly. This may include buttons that do not work, switches that do not engage, or a lack of response when adjusting settings. 2. Inaccurate readings: Another sign of a faulty control box is when the readings or measurements displayed on the control panel are inaccurate or inconsistent. This may include incorrect pressure readings, flow rates, or other important measurements necessary for proper pump operation. 3. Electrical issues: Faulty control boxes can also cause electrical problems such as flickering lights, sudden power surges or shortages, or even blown fuses. These electrical issues can be dangerous and may lead to further damage if not addressed promptly. 4. Strange noises: When a control box is faulty, it may produce strange noises, such as buzzing, humming, or clicking sounds. These noises can indicate loose connections, damaged components, or malfunctioning parts within the control box. 5. Pump malfunctions: A faulty control box can also cause the concrete pump itself to malfunction. This may include issues such as inconsistent pumping, irregular flow, or sudden stops and starts. These problems can disrupt the concrete pouring process and potentially lead to project delays. If you suspect a faulty concrete pump control box, it is crucial to address the issue promptly. It is recommended to consult a qualified technician or contact the manufacturer for assistance in diagnosing and repairing the control box.

- Q: How often should hydraulic filters be replaced in a concrete pump?

- To ensure optimal performance and longevity of the equipment, it is important to regularly replace the hydraulic filters in a concrete pump. The frequency of replacement will depend on factors such as the specific model of the concrete pump, the operating conditions, and the quality of hydraulic fluid used. As a general rule, it is recommended to replace the hydraulic filters every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, it is crucial to consult the manufacturer's recommendations and guidelines for the specific model of the concrete pump, as they may have specific maintenance schedules and intervals. Regularly inspecting the hydraulic filters is also vital to determine if replacement is necessary before the recommended interval. If the filters are clogged, damaged, or show signs of excessive wear, immediate replacement is necessary to prevent potential damage to the hydraulic system. Additionally, if the concrete pump operates in harsh or dusty environments, more frequent filter replacements may be required to ensure proper filtration and prevent contamination. In conclusion, timely and proper replacement of hydraulic filters in a concrete pump is crucial to maintain efficiency and reliability, prevent breakdowns, and prolong the service life of the equipment.

- Q: Can I use alternative materials for concrete pump spare parts?

- Yes, alternative materials can be used for concrete pump spare parts. However, it is important to ensure that these materials meet the required specifications and standards for durability, strength, and compatibility with the concrete pumping system. Additionally, it is advisable to consult with professionals or manufacturers to ensure the safe and efficient functioning of the equipment.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, you can definitely get spare parts for concrete pump boom arms and pipes. There are various suppliers and manufacturers that specialize in providing spare parts for concrete pumps. These spare parts include boom arms, pipes, couplings, gaskets, seals, and other components that are necessary for the proper functioning of a concrete pump. You can search for these spare parts online, where you will find numerous websites and online stores that offer a wide range of options. It is important to ensure that you purchase spare parts from reputable suppliers to ensure their quality and compatibility with your specific concrete pump model. Additionally, there are also local dealers and distributors who stock spare parts for concrete pumps. You can inquire with them or visit their stores to find the required spare parts for your boom arms and pipes. Regular maintenance and replacement of worn-out or damaged parts is crucial for the efficient and safe operation of a concrete pump. By investing in high-quality spare parts, you can extend the lifespan of your equipment and ensure its optimal performance.

- Q: What is the role of a concrete pump hopper agitator shaft?

- The role of a concrete pump hopper agitator shaft is to ensure the consistent and uniform mixing of concrete within the hopper. The agitator shaft is typically fitted with a series of paddles or blades that rotate within the hopper, effectively stirring the concrete and preventing it from settling or separating. This helps to maintain the desired fluidity and consistency of the concrete, allowing for smooth and efficient pumping without any blockages or clogs. The agitator shaft also helps to dislodge any hardened or stuck concrete, ensuring that the hopper remains clean and free from any obstructions. Overall, the agitator shaft plays a crucial role in keeping the concrete well-mixed and ready for pumping, thereby enhancing the performance and productivity of the concrete pump.

Send your message to us

Concrete Pump Hardened Pipe DN125 High Endurable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords