DN125 Hardened Pipe of Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN125 Hardened Pipe of Schwing Concrete Pump

1. Structure of DN125 Hardened Pipe of Schwing Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of DN125 Hardened Pipe of Schwing Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

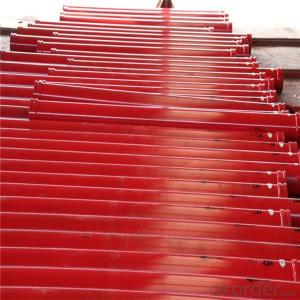

3. DN125 Hardened Pipe of Schwing Concrete Pump Images:

4. DN125 Hardened Pipe of Schwing Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

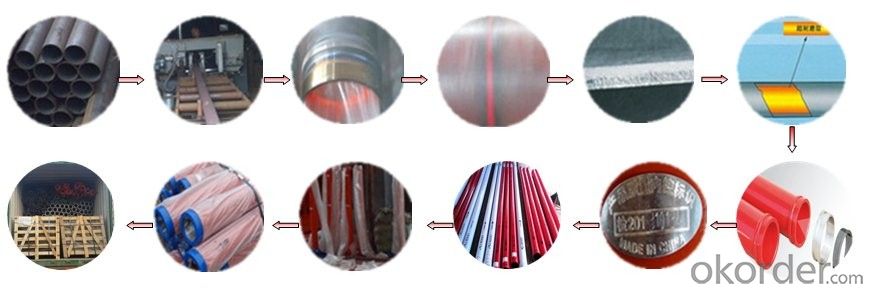

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: How can a faulty filter affect the pumping process?

- A faulty filter can significantly affect the pumping process in several ways. Firstly, a faulty filter may become clogged or blocked, hindering the flow of fluid through the pump. This can result in reduced efficiency and increased energy consumption as the pump has to work harder to overcome the resistance caused by the clogged filter. The decreased flow rate can also lead to longer pumping times, which can be problematic in time-sensitive applications. Secondly, a faulty filter may fail to effectively remove impurities or contaminants from the fluid being pumped. This can be particularly problematic in industries where maintaining the purity or cleanliness of the fluid is crucial, such as in pharmaceutical or food processing applications. The presence of contaminants can compromise the quality of the final product or damage equipment downstream from the pump. Furthermore, a faulty filter can lead to increased maintenance and repair costs. If the filter is not functioning properly, it may allow larger particles or debris to pass through, which can cause damage to the pump components. This can result in increased wear and tear, decreased lifespan of the pump, and the need for more frequent repairs or replacements. Lastly, a faulty filter can also pose a risk to the overall system and its components. If the filter fails completely, it may allow foreign objects or particles to enter the pump, leading to potential blockages, damage to internal components, or even complete failure of the pump. This can result in costly downtime, loss of production, and the need for emergency repairs or replacements. In summary, a faulty filter can have detrimental effects on the pumping process, including decreased efficiency, compromised fluid quality, increased maintenance costs, and potential damage to the pump and system components. Regular inspection, maintenance, and timely replacement of filters are essential to ensure smooth and reliable operation of pumps in various industries.

- Q: How can one differentiate between genuine and counterfeit concrete pump spare parts?

- Differentiating between genuine and counterfeit concrete pump spare parts can be a challenging task, but there are several ways to ensure you are purchasing authentic components. Here are some strategies to consider: 1. Research the Manufacturer: Start by conducting thorough research on the manufacturer of the concrete pump spare parts. Look for reputable and established companies with a proven track record. Check their website, read customer reviews, and analyze their industry standing. Genuine manufacturers usually have a strong online presence and provide detailed information about their products. 2. Verify the Supplier: When purchasing spare parts, it is crucial to choose a reliable and authorized supplier. Make sure the supplier has a good reputation in the industry and has been in the business for an extended period. Authorized distributors often have a direct relationship with the manufacturer and can provide genuine parts. 3. Inspect Product Packaging: Genuine concrete pump spare parts often have specific packaging that includes branding, logos, and detailed product information. Counterfeit products may have poor quality packaging or contain misspellings, incorrect logos, or inconsistent color schemes. Examine the packaging closely to determine its authenticity. 4. Check Product Quality and Finish: Counterfeit parts are often made from low-quality materials and lack the precision and finish of genuine parts. Inspect the spare parts for any signs of poor workmanship, rough edges, or uneven surfaces. Genuine parts are usually well-crafted and undergo strict quality control measures. 5. Compare Prices: Be cautious of significantly lower prices for spare parts, as it could be an indication of counterfeit products. Counterfeiters often sell their goods at a lower price to attract customers, but the quality and performance may be compromised. Compare prices with other suppliers to ensure they are within the expected range. 6. Seek Expert Advice: If you're uncertain about the authenticity of concrete pump spare parts, consult with industry experts or experienced professionals. They can guide you in identifying genuine components and help you make informed decisions. 7. Request Certifications and Documentation: Genuine manufacturers provide certifications and documentation, such as ISO certifications or test reports, to validate the quality and authenticity of their products. Ask the supplier for these documents and verify their legitimacy with the manufacturer if necessary. Remember, purchasing genuine concrete pump spare parts is essential for the safety and efficiency of your equipment. By following these steps and exercising caution, you can minimize the risk of buying counterfeit components and ensure the longevity and reliable performance of your concrete pump.

- Q: What are the specifications for concrete delivery pumps?

- The pressure of each safety valve of the hydraulic system of concrete pump shall comply with the requirements of the manual, and the user shall not adjust the change

- Q: How often should concrete pump hydraulic oil coolers be inspected and maintained?

- To guarantee optimal performance and avoid possible problems, it is necessary to carry out regular inspections and maintenance on the hydraulic oil coolers of concrete pumps. The frequency of these procedures will vary depending on factors such as the pump's operating conditions, workload, and the recommendations provided by the manufacturer. As a general rule, it is advisable to inspect and maintain the concrete pump hydraulic oil coolers at least once every six months or every 500-700 operating hours, whichever comes first. However, in more demanding or extreme operating conditions, it may be necessary to perform these tasks more frequently. During these inspections, it is of utmost importance to thoroughly clean the cooler and examine it for any signs of damage, corrosion, or leaks. It is also crucial to inspect the cooler's fins for any blockages, as the presence of debris or dirt can decrease its efficiency. Regularly checking and replacing the air filters of the cooler is equally important to ensure proper airflow and prevent overheating. In terms of regular maintenance, it is vital to replace the hydraulic oil and filters according to the manufacturer's recommendations. This action helps maintain the oil's viscosity and prevents any contaminants from causing damage to the cooler or other hydraulic components. To summarize, conducting regular inspections and maintenance on concrete pump hydraulic oil coolers is crucial to ensure efficient operation and prolong their lifespan. By adhering to the manufacturer's guidelines and taking into account specific operating conditions, it is possible to determine the appropriate frequency for these inspections and maintenance tasks.

- Q: Can a concrete pump wear plate be repaired or does it need to be replaced entirely?

- A concrete pump wear plate can be repaired in certain situations, but sometimes it may need to be replaced entirely. The decision whether to repair or replace the wear plate depends on the extent of the damage and the overall condition of the plate. Minor damages such as small cracks, dents, or worn out areas can often be repaired using suitable techniques. For example, if there are small cracks, they can be welded or filled with an appropriate epoxy or filler material. Similarly, if there are dents or worn out areas, they can be filled and smoothened to restore the plate's functionality. However, if the wear plate has suffered significant damage, such as extensive cracks, severe corrosion, or large holes, it may be better to replace the plate entirely. This is because repairing such extensive damage may compromise the structural integrity and effectiveness of the wear plate. In these cases, replacing the wear plate ensures the optimal performance and safety of the concrete pump. It is crucial to assess the condition of the wear plate carefully before deciding whether to repair or replace it. Consulting with experts or professionals familiar with concrete pump maintenance can provide valuable guidance in making the right decision. Furthermore, regular maintenance and inspection of the wear plate can help identify any potential issues early on, allowing for timely repairs or replacements to prevent further damage and ensure the efficient operation of the concrete pump.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of seal kits or O-rings. Here are some general guidelines you should follow: 1. Prioritize safety: Before attempting installation, make sure the concrete pump is turned off and depressurized. Protect yourself by wearing appropriate safety gear like gloves and goggles. 2. Prepare the area: Thoroughly clean the installation area to ensure a smooth and debris-free surface for the seal kits or O-rings. 3. Inspect the parts: Before installation, carefully examine the seal kits or O-rings for any defects or damage. Replace any faulty parts with new ones. 4. Apply lubrication: To facilitate installation and prevent damage, use a small amount of compatible lubricant or hydraulic oil on the seal kits or O-rings. Ensure the lubricant is suitable for the materials used. 5. Align correctly: Align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Make sure they are properly seated and positioned. 6. Install properly: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid applying excessive force or bending, as this can cause damage or improper sealing. 7. Test for functionality: After installation, test the concrete pump to ensure the seal kits or O-rings are functioning properly. Check for leaks or any abnormal behavior during operation. 8. Maintain regularly: Regular inspection and maintenance are crucial for the longevity and optimal performance of the seal kits or O-rings. Follow the manufacturer's recommended maintenance schedule and guidelines. It's important to note that these guidelines are general and may vary depending on the specific make and model of the concrete pump. Always consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- To ensure optimal performance and longevity of your equipment, it is crucial to properly maintain and replace filters in concrete pump spare parts. Here are some guidelines to follow: 1. Get familiar with the different types of filters: Concrete pumps have various filters for hydraulic oil, fuel, air, and water. Take the time to understand which filters are used in your equipment. 2. Consult the manufacturer's instructions: Read the equipment manual and adhere to the guidelines provided by the manufacturer regarding filter maintenance and replacement intervals. This will ensure that you are following the recommended practices. 3. Conduct regular filter inspections: Periodically check the filters for signs of damage, clogging, or excessive debris accumulation. You can visually inspect them or measure the pressure differential across the filter. If the pressure differential exceeds the recommended limit, it may be necessary to replace the filter. 4. Clean or replace filters as required: If the filters are clogged or dirty, they should be cleaned or replaced. Some filters can be cleaned by blowing compressed air in the opposite direction of the airflow to remove debris. However, it is important to note that certain filters are disposable and cannot be cleaned. 5. Use authentic spare parts: When replacing filters, always opt for genuine spare parts recommended by the manufacturer. This ensures compatibility and performance. 6. Follow proper handling and installation procedures: When installing new filters, make sure to handle them with clean hands or wear gloves to prevent contamination. Follow the correct installation procedure, such as tightening the filter housing to the recommended torque value. 7. Maintain a regular maintenance schedule: Establish a consistent schedule for filter inspection, cleaning, and replacement. This will help you stay on top of filter maintenance and prevent potential issues caused by dirty or clogged filters. By adhering to these steps, you can effectively maintain and replace filters in concrete pump spare parts, ensuring efficient equipment operation and an extended lifespan.

- Q: How do I properly maintain and replace hydraulic filters in concrete pump spare parts?

- To properly maintain and replace hydraulic filters in concrete pump spare parts, follow these steps: 1. Regularly inspect the hydraulic filters for any signs of damage, clogs, or excessive dirt accumulation. 2. If the filter is damaged or excessively dirty, replace it immediately to ensure the proper functioning of the hydraulic system. 3. Before replacing the filter, ensure that the hydraulic system is depressurized to avoid any accidents. 4. Carefully remove the old filter and dispose of it properly. 5. Clean the filter housing thoroughly to remove any debris or contaminants. 6. Install the new hydraulic filter, ensuring that it is properly seated and secured in place. 7. Double-check that all connections and fittings are tight to prevent any leakage. 8. Once the new filter is in place, refill the hydraulic system with the recommended hydraulic fluid. 9. After replacing the filter, run the concrete pump and observe for any abnormal sounds, leaks, or pressure fluctuations. 10. Maintain a regular filter replacement schedule based on the manufacturer's recommendations to ensure optimal performance and prevent potential damage to the hydraulic system.

- Q: How can one identify the correct thread size and type for concrete pump spare parts?

- To identify the correct thread size and type for concrete pump spare parts, there are a few steps one can follow: 1. Refer to the equipment manual: The first step is to consult the manual or documentation that came with the concrete pump. It often contains detailed information about the thread sizes and types used for different parts. 2. Measure the existing part: If the manual is not available or does not provide the necessary information, one can take measurements of the existing part. Use a caliper or a thread gauge to measure the diameter and pitch of the thread. This will help determine the correct size and type needed for replacement. 3. Seek assistance from the manufacturer: If the manual or measurements do not provide satisfactory results, it is advisable to reach out to the manufacturer or supplier of the concrete pump. They have expert knowledge about the specific thread sizes and types used in their equipment and can guide you in finding the correct spare parts. 4. Consult industry standards: Depending on the region and type of concrete pump, there may be industry standards or norms that dictate the thread sizes and types used in these machines. Researching and referencing these standards can provide valuable insights into the correct specifications for spare parts. 5. Engage with experienced professionals: Another effective way to identify the correct thread size and type is to seek advice from experienced professionals in the concrete pumping industry. They may have encountered similar situations and can provide guidance based on their expertise. Overall, a combination of consulting equipment manuals, measuring existing parts, contacting the manufacturer, studying industry standards, and seeking advice from professionals can help in identifying the correct thread size and type for concrete pump spare parts.

- Q: How often should concrete pump electric motors be inspected and maintained?

- Concrete pump electric motors should be inspected and maintained regularly to ensure their optimal performance and longevity. It is recommended to have them inspected at least once a year or every 500-1000 operating hours, whichever comes first. Additionally, regular maintenance should be carried out based on the manufacturer's guidelines and recommendations. This may include checking and replacing worn-out parts, lubricating moving components, cleaning dust and debris, and inspecting electrical connections for any signs of damage or loose connections. Adhering to a regular inspection and maintenance schedule will help prevent potential breakdowns, increase the lifespan of the motor, and ensure the concrete pump operates efficiently.

Send your message to us

DN125 Hardened Pipe of Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords