3M Concrete Pump St52 Weld Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Concrete Pump St52 Weld Delivery Pipe

1. Structure of 3M Concrete Pump St52 Weld Delivery Pipe:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Concrete Pump St52 Weld Delivery Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

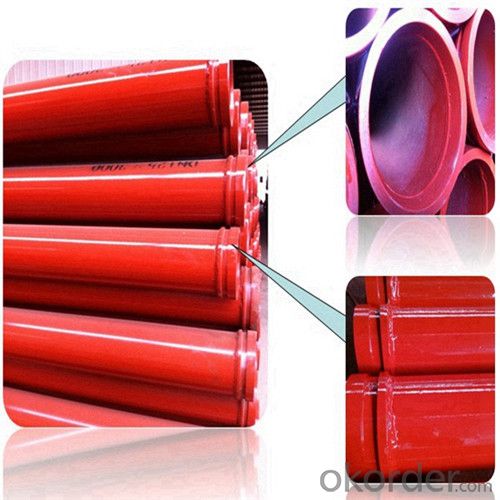

3. 3M Concrete Pump St52 Weld Delivery Pipe Images

4. 3M Concrete Pump St52 Weld Delivery Pipe Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines are important to ensure the proper functioning and accurate readings of the sensors or transmitters. Firstly, it is crucial to carefully select the location for installing the sensors or transmitters. The chosen location should allow for easy access and maintenance, while also ensuring that the sensors or transmitters are not exposed to excessive vibration, moisture, or extreme temperatures. Secondly, it is recommended to use appropriate mounting hardware for securing the sensors or transmitters to the concrete pump spare parts. This hardware should be able to withstand the operating conditions and any potential vibrations or shocks that may occur during the pumping process. Additionally, it is important to follow the manufacturer's instructions for wiring and connection of the sensors or transmitters. Proper wiring and connection are essential to ensure accurate and reliable data transmission. Furthermore, regular inspections and maintenance should be conducted to ensure that the sensors or transmitters are functioning correctly. This includes checking for any loose connections, signs of wear or damage, and ensuring that the sensors or transmitters are calibrated properly. Overall, following these specific guidelines for the installation of sensors or transmitters in concrete pump spare parts can help to ensure their optimal performance and longevity, ultimately enhancing the efficiency and safety of the concrete pumping operation.

- Q: Can concrete pump spare parts be heat-treated or hardened for increased durability?

- Concrete pump spare parts can undergo heat treatment or hardening to increase their durability. By subjecting the parts to controlled heating and cooling processes, their mechanical properties can be altered. This alteration significantly improves their hardness, strength, and wear resistance, thus enhancing their durability and ability to withstand harsh operating conditions. Various heat treatment methods, such as quenching and tempering, induction hardening, and case hardening, can be applied to different types of spare parts, including cylinders, pistons, wear plates, and delivery pipes. These processes contribute to the overall performance and lifespan of the spare parts, ensuring their ability to withstand the demanding nature of concrete pumping operations.

- Q: How can one identify the correct part number for a specific concrete pump spare part?

- To find the appropriate part number for a specific spare part for your concrete pump, there are several steps you can take: 1. Refer to the equipment manual: Start by checking the manual that accompanies your concrete pump. It should contain a comprehensive list of parts, complete with their corresponding part numbers. This is the most reliable and accurate source of information. 2. Get in touch with the manufacturer: If you don't have access to the equipment manual or it doesn't provide the necessary details, reach out to the manufacturer directly. They should be able to help you identify the correct part number for the specific spare part you require. Provide them with as much information as possible, such as the concrete pump's make, model, and serial number. 3. Utilize online resources: There are various online platforms and parts catalogs available that offer detailed information about spare parts for different concrete pump brands and models. These resources often allow you to search for the part based on your concrete pump's make and model. However, make sure to cross-reference the information with the manufacturer's specifications to ensure accuracy. 4. Seek advice from a local dealer or distributor: If you're unable to find the correct part number through the aforementioned methods, consider contacting a local dealer or distributor specializing in concrete pump spare parts. They typically possess extensive knowledge and experience in identifying and sourcing the right parts for various equipment. Provide them with all the necessary details about your concrete pump, and they should be able to assist you in finding the correct part number. Remember, accuracy is crucial when determining the correct part number for a specific concrete pump spare part. Relying on trustworthy sources and consulting professionals will help guarantee that you obtain the appropriate part to meet your equipment's requirements.

- Q: What are the different types of concrete pump control system sensors?

- Concrete pump control systems utilize a variety of sensors to ensure smooth and efficient operation. These sensors are specifically designed to monitor different aspects of the pump's performance and provide real-time feedback to the control system. Common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors measure the concrete pressure during pumping. They are typically installed in the discharge line and are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors measure the rate at which concrete flows through the system. By monitoring the volume of concrete passing through per unit of time, these sensors enable the control system to regulate the pump's speed and output accordingly. 3. Level Sensors: Level sensors monitor the concrete level in the hopper or storage tank. They provide information about the concrete volume to prevent the pump from running dry or becoming overloaded, thus preventing pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors detect the position of moving parts in the pump system, such as the boom or outriggers. They ensure safe operation by providing feedback to the control system and preventing collisions or obstructions. 5. Temperature Sensors: Temperature sensors monitor the concrete mix temperature. They help maintain the desired temperature range during pumping, which is crucial for workability and curing. Optimal concrete temperature contributes to the quality of the final product. In summary, these sensors work in harmony to provide precise feedback to the control system, ensuring efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, these sensors optimize pumping performance and enhance productivity in concrete placement projects.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Yes, there are warranties and guarantees available for concrete pump spare parts. Many manufacturers and suppliers offer warranties to ensure the quality and performance of their products. These warranties typically cover defects in materials or workmanship and provide a certain period of coverage, usually ranging from a few months to a year or more. Additionally, some suppliers may offer guarantees on the performance or durability of their spare parts, providing assurance and peace of mind to the customers. It is always recommended to inquire about the specific warranty or guarantee terms before purchasing concrete pump spare parts to ensure that you are protected in case of any issues.

- Q: Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control panels or electronic components in concrete pump spare parts. When installing control panels or electronic components in concrete pump spare parts, it is important to consider the following guidelines: 1. Protection from Moisture: Concrete pump spare parts are exposed to moisture, which can be detrimental to electronic components. It is advisable to install control panels or electronic components in waterproof or moisture-resistant enclosures to prevent damage from water or humidity. 2. Vibration and Shock Absorption: Concrete pump spare parts are subject to vibration and shock during operation. To prevent damage to control panels or electronic components, it is recommended to use shock-absorbing mounts or vibration-resistant enclosures to minimize the impact of these forces. 3. Temperature Control: Concrete pump spare parts can be exposed to extreme temperatures, both hot and cold. It is crucial to ensure that control panels or electronic components are installed in a temperature-controlled environment. This may involve using insulation or cooling systems to maintain a suitable operating temperature range. 4. Wiring and Connections: Proper wiring and connections are essential for the functioning of control panels or electronic components. It is important to follow the manufacturer's instructions and guidelines for wiring, ensuring that connections are made securely and that proper insulation and protection are provided to prevent short circuits or electrical hazards. 5. Accessibility and Maintenance: Control panels or electronic components should be installed in a manner that allows easy accessibility for maintenance and repairs. It is recommended to leave enough space around the components for easy inspection, servicing, and replacement if necessary. By adhering to these guidelines, the installation of control panels or electronic components in concrete pump spare parts can be done in a manner that ensures their long-term functionality and durability.

- Q: Are there any specific quality control measures for the production of concrete pump spare parts?

- Yes, there are specific quality control measures for the production of concrete pump spare parts. These measures are put in place to ensure that the spare parts meet the required specifications and are of high quality. One of the key quality control measures is the use of standardized production processes. Manufacturers follow specific procedures and guidelines to produce the spare parts, ensuring consistency and accuracy in the manufacturing process. This includes using quality materials, following precise measurements, and employing advanced manufacturing techniques. Quality control also involves rigorous testing and inspection of the spare parts throughout the production process. This includes conducting dimensional checks, hardness tests, and material composition analysis, among others. These tests help identify any defects or deviations from the required standards, allowing for timely corrective actions. Additionally, manufacturers may implement quality management systems, such as ISO 9001, to ensure continuous improvement in their production processes. These systems help establish quality objectives, monitor performance, and implement corrective actions when necessary. Furthermore, manufacturers may engage in third-party quality assessment and certification programs. This involves independent organizations conducting audits and inspections to ensure that the spare parts meet the required quality standards. Certifications from these programs provide assurance to customers about the quality and reliability of the spare parts. Overall, the production of concrete pump spare parts undergoes stringent quality control measures to ensure that they meet the necessary specifications and are of high quality. These measures help maintain the performance and durability of the spare parts, ensuring their reliability in concrete pump applications.

- Q: What are the common issues that require replacement of concrete pump spare parts?

- Common issues that often require the replacement of concrete pump spare parts include wear and tear from continuous use, damage caused by debris or foreign objects in the concrete mix, corrosion due to exposure to harsh chemicals or weather conditions, and malfunctioning or worn-out components such as seals, valves, or pistons.

- Q: How can one ensure proper alignment and positioning of concrete pump spare parts during installation?

- Ensuring proper alignment and positioning of concrete pump spare parts during installation is crucial for the efficient and safe operation of the pump. Here are some key steps to follow to achieve the desired alignment and positioning: 1. Thoroughly read and understand the manufacturer's instructions: Before starting the installation process, carefully go through the manufacturer's instructions and guidelines. This will provide you with important information on the correct alignment and positioning of the spare parts specific to your concrete pump model. 2. Prepare a suitable work area: Clear the work area of any debris, dust, or obstacles that might hinder the installation process. Ensuring a clean and organized work environment will make it easier to position and align the spare parts accurately. 3. Utilize proper lifting equipment: Concrete pump spare parts can be heavy and require special lifting equipment to avoid damage or injuries. Use cranes, hoists, or forklifts to lift and position the spare parts accurately and safely. 4. Use precision measuring tools: Invest in high-quality measuring tools, such as laser levels, alignment guides, and precision measuring tapes. These tools will help you ensure precise alignment and positioning of the spare parts during installation. 5. Double-check dimensions and specifications: Before installing any spare part, cross-check the dimensions and specifications provided by the manufacturer with the actual part. This will help you identify any discrepancies or potential issues that need to be addressed before installation. 6. Follow a systematic installation process: Start with the main components of the concrete pump and gradually work your way towards the spare parts. Follow a step-by-step approach, aligning and positioning each spare part meticulously according to the manufacturer's instructions. 7. Seek professional assistance if needed: If you are unsure about the proper alignment and positioning of certain spare parts, do not hesitate to seek professional assistance. Consulting with experienced technicians or contacting the manufacturer's customer support can provide valuable guidance and ensure correct installation. 8. Conduct a final inspection: Once all the spare parts are installed, conduct a thorough inspection to verify the alignment and positioning. Check for any visible gaps, misalignments, or irregularities. Rectify any issues immediately to ensure proper function and longevity of the concrete pump. By following these steps and paying attention to detail, you can ensure the proper alignment and positioning of concrete pump spare parts during installation, resulting in a reliable and efficient pump system.

- Q: How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- To ensure the concrete pump operates efficiently and safely, it is crucial to properly maintain and replace the concrete delivery pipes in spare parts. Here are some guidelines you can adhere to: 1. Conduct Regular Inspections: Frequently check the concrete delivery pipes for signs of wear, cracks, or damage. Look out for leaks or blockages that may hinder the concrete flow. Identify weak areas that may necessitate replacement. 2. Perform Thorough Cleaning: After each use, clean the concrete delivery pipes meticulously. Use water and a high-pressure hose to eliminate any concrete residue or buildup. This will prevent clogs and maintain a smooth concrete flow. 3. Apply Lubrication: Reduce friction and prevent concrete from adhering to the inner surface of the pipes by applying a suitable lubricant. This practice will elongate the life of the pipes and guarantee a seamless concrete flow. 4. Replace Worn-out Components: Regularly monitor the condition of the delivery pipes and promptly replace any worn-out or damaged parts. Over time, the pipes may corrode or develop cracks, thereby affecting their performance. Replace these components with premium spare parts to achieve optimal outcomes. 5. Handle with Care: Exercise caution when handling the concrete delivery pipes to avoid unnecessary damage. Refrain from dropping or mishandling the pipes during transportation or storage. Shield them from extreme weather conditions and store them in a secure, dry location. 6. Prioritize Training and Safety: Ensure that the personnel operating the concrete pump are well-versed in handling and maintaining the equipment. Educate them on the significance of regular inspections, cleaning, and part replacement. Emphasize safety protocols to prevent accidents and ensure the durability of the concrete delivery pipes. By adhering to these steps, you can effectively maintain and replace the concrete delivery pipes in spare parts for the concrete pump. Consistent maintenance and prompt part replacement will extend the lifespan of the pipes and guarantee a seamless concrete flow during construction projects.

Send your message to us

3M Concrete Pump St52 Weld Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords