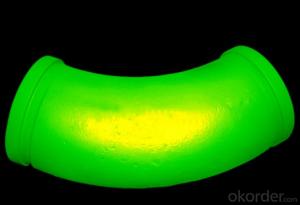

Concrete Pump ELBOW R275, 90DGR DN125MM with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Concrete Pump ELBOW R275, 90DGR DN125MM

1. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275, 90DGR DN125MM widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275, 90DGR DN125MM put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump Concrete Pump ELBOW R275, 90DGR DN125MM according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275, 90DGR DN125MM according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the specifications for concrete delivery pumps?

- In the hot season construction, concrete pump to prevent the oil temperature is too high. When the temperature reaches 70 degrees, stop running or take other measures to cool down;

- Q: What are the indications of a faulty control lever?

- There are multiple indications that may suggest a malfunctioning control lever. Firstly, if the control lever does not respond or is sluggish when attempting to engage or disengage a specific function, it could be indicative of an issue. This may include difficulties in shifting gears, adjusting speed, or operating various controls such as the throttle or clutch. Another sign of a faulty control lever is if it becomes loose or unstable. If you observe excessive play or movement in the lever, it could imply that the mechanism connecting the lever to the control system is worn out or damaged. This can compromise the accuracy and precision of the control lever, making it challenging to effectively operate the intended functions. Furthermore, any unusual noises or vibrations originating from the control lever can serve as an indication of a fault. This might be a consequence of loose or broken components within the control lever assembly, suggesting the need for inspection and repair. Lastly, if the control lever becomes stuck or jammed in a particular position, it clearly signifies a faulty lever. This can hinder proper control of the equipment or vehicle, posing safety risks. In any case, if there is suspicion of a faulty control lever, it is crucial to have it inspected and repaired by a qualified technician to ensure proper functioning and safe operation.

- Q: How often should concrete pump pistons be replaced?

- The frequency of replacing concrete pump pistons can vary depending on several factors such as the type of pump, the quality of the pistons, and the intensity of usage. However, as a general guideline, concrete pump pistons should be inspected regularly and replaced whenever signs of excessive wear or damage are observed. Timely replacement is crucial to ensure optimal pumping performance and prevent potential breakdowns.

- Q: What are the different sizes of concrete pump pipes available?

- The sizes of concrete pump pipes typically range from 2 inches to 6 inches in diameter.

- Q: How often should hopper agitator shaft bearings be inspected or replaced in a concrete pump?

- The hopper agitator shaft bearings in a concrete pump should be inspected regularly, at least once every six months, to ensure proper functioning. However, the exact frequency of replacement would depend on the manufacturer's recommendations, the intensity of usage, and the condition of the bearings. It is crucial to monitor the bearings for any signs of wear, damage, or excessive vibration, as this can lead to equipment failure and potential safety hazards.

- Q: What is the function of a concrete pump remote control?

- The concrete pump remote control is a tool that enables the operation and control of a concrete pump from a distance. It grants the operator the ability to manipulate various aspects of the pump's functioning, including initiating and terminating the pumping process, adjusting the pump's speed and direction, and governing the placement and flow of the concrete. Through its capacity for remote control, it eliminates the necessity for the operator to be in close physical proximity to the pump, thereby enabling a safer and more efficient operation. Furthermore, the remote control frequently incorporates additional features, such as emergency stop buttons, diagnostics, and data logging capabilities, which further augment the functionality and dependability of the concrete pump. In summary, the concrete pump remote control serves to provide convenience, accuracy, and safety in the operation of concrete pumping equipment.

- Q: Can concrete pump spare parts be purchased online?

- Yes, concrete pump spare parts can be purchased online. There are various online platforms and websites that specialize in selling construction equipment and spare parts, including concrete pump spare parts. These online stores offer a wide range of options and brands, allowing customers to browse and select the specific spare parts they need for their concrete pump. Additionally, online purchasing provides the convenience of comparing prices, reading customer reviews, and having the spare parts delivered to your doorstep. However, it is essential to ensure the authenticity and reliability of the online store before making a purchase to ensure that you are getting genuine and high-quality spare parts.

- Q: What are the signs of a damaged or malfunctioning electric motor?

- Some signs of a damaged or malfunctioning electric motor may include unusual noises such as grinding or screeching, overheating, excessive vibration, sudden power loss or fluctuations, and a burning smell.

- Q: How to judge the concrete pipeline blockage?

- Judgment of blocking position: blockage usually occurs in bends, cones, and vibrating sections. At this point, the hammer can be beaten along the pipe, the sound is boring, blocking the place; sound crisp place is normal

- Q: How often should concrete pump remote control batteries be replaced?

- Concrete pump remote control batteries should be replaced as needed, typically when they no longer hold a charge or fail to power the remote control effectively. The frequency of replacement will depend on factors such as battery quality, usage, and maintenance.

Send your message to us

Concrete Pump ELBOW R275, 90DGR DN125MM with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords