Concrete Pump ELBOW R275, 45DGR Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

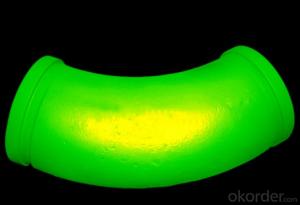

Product Name: Concrete Pump ELBOW R275, 45DGR DN125MM Grey with High Quality

1. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275, 45DGR DN125MM Grey widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275, 45DGR DN125MM Grey put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Concrete pump spare parts may exhibit signs of wear and tear, which should not be overlooked. Some indicators include: 1. Surface damage: Cracks, dents, or scratches on pipes and hoses can signify wear and tear, particularly if they are extensive or deep. 2. Corrosion: Metal components like couplings or clamps may display signs of corrosion such as rusting or pitting, which can weaken the part and affect its functionality. 3. Leaks: Notable leaks in seals or gaskets can suggest wear and tear. Material degradation or improper installation can cause leaks, impacting the pump's efficiency and performance. 4. Decreased performance: Wear and tear in concrete pump spare parts can result in reduced overall performance. For instance, worn-out wear plates can diminish pumping capacity or increase energy consumption. 5. Heightened noise or vibrations: If noise levels or vibrations intensify while operating the concrete pump, it may indicate wear and tear in the spare parts. Imbalances, misalignments, or loose components can negatively affect the pump's performance and lifespan. 6. Excessive wear on moving parts: Moving parts like pistons or cylinders may exhibit excessive wear and tear, such as scoring or grooving on the surface. This can impede the smooth operation of the pump and potentially cause further damage if left unaddressed. Regular inspection and maintenance of concrete pump spare parts are vital to promptly identify and address any signs of wear and tear. Timely replacement or repair of worn-out components can prevent further damage, ensuring the concrete pump operates efficiently and safely.

- Q: How can a faulty filter affect the pumping process?

- A faulty filter can impede the pumping process by allowing debris, contaminants, or particles to pass through and clog or damage the pump components. This can result in reduced efficiency, increased wear and tear, decreased flow rates, and potential pump failure.

- Q: What are the indicators of a faulty concrete pump seal?

- Some indicators of a faulty concrete pump seal include leakage of hydraulic fluid, loss of pressure during operation, unusual noises or vibrations, and difficulty in maintaining consistent flow of concrete.

- Q: Can concrete pump spare parts be coated with UV-resistant coatings for outdoor applications?

- Concrete pump spare parts can benefit from the application of UV-resistant coatings to protect them from the damaging effects of UV radiation. These coatings are specially designed to prevent fading, cracking, and deterioration over time. By coating the spare parts, they are shielded from prolonged exposure to sunlight and other environmental factors, thus extending their lifespan and ensuring optimal performance outdoors. Furthermore, these coatings offer additional protection against weathering, including moisture, temperature fluctuations, and chemical exposure. As a result, it is highly recommended to coat concrete pump spare parts with UV-resistant coatings in order to enhance their durability and maintain their functionality when used outside.

- Q: Are there any specific guidelines for the installation of control valves or solenoids in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of control valves or solenoids. Consider the following general guidelines: 1. Compatibility: Ensure that the control valves or solenoids being installed are compatible with the concrete pump spare parts. Refer to the manufacturer's specifications and guidelines to determine the appropriate model and size. 2. Proper Positioning: Install the control valves or solenoids in a position that allows for easy access and maintenance. They should be easily visible and reachable for adjustments or repairs. 3. Mounting: Securely mount the control valves or solenoids to prevent any vibrations or movements during operation. This will ensure the stability and durability of the components. 4. Electrical Connections: Follow the manufacturer's instructions for electrical wiring. Connect the control valves or solenoids to the correct power source and ensure proper grounding to avoid electrical hazards. 5. Sealing: Use suitable sealing materials, such as gaskets or O-rings, to create a tight and leak-free connection between the control valves or solenoids and other components. This will prevent any fluid or air leakage. 6. Testing: After installation, it is crucial to thoroughly test the functionality of the control valves or solenoids. Check for leaks, proper operation, and responsiveness to control signals. Address and resolve any issues before operating the concrete pump. Remember that these guidelines are general, and specific manufacturer recommendations and the design of the concrete pump spare parts may vary. Always refer to the manufacturer's guidelines and instructions for the specific control valves or solenoids being used.

- Q: Are there any specific regulations or standards for the labeling and packaging of concrete pump spare parts?

- Concrete pump spare parts are subject to specific regulations and standards regarding their labeling and packaging. These regulations and standards aim to guarantee safety, proper handling, and ease of identification for these spare parts. A key regulation requires clear and legible labeling on the packaging of concrete pump spare parts. This labeling must include essential information such as the manufacturer's name, part number, description, as well as any specific instructions or warnings for handling and installation. This ensures that users can easily identify the spare parts and comprehend their purpose and correct usage. Furthermore, specific standards may exist for the packaging material utilized for concrete pump spare parts. These standards may demand the use of durable and protective packaging materials to prevent damage during transportation and storage. By doing so, the quality and functionality of the spare parts are preserved until they are ready for use. Moreover, regulations may be in place regarding the labeling and packaging of spare parts concerning safety. For instance, certain spare parts may necessitate special labeling or packaging to indicate the presence of hazardous materials or potential risks if mishandled. This is crucial for ensuring the safety of those handling the spare parts and for compliance with relevant safety regulations. In conclusion, the labeling and packaging of concrete pump spare parts are governed by specific regulations and standards to ensure proper identification, handling, and safety. These regulations and standards play a vital role in upholding a high level of quality and reliability for these spare parts within the construction industry.

- Q: How often should concrete pump seals be replaced?

- The replacement of concrete pump seals depends on various factors, such as the type of pump, seal quality, operating conditions, and maintenance practices. It is generally recommended to inspect and replace the seals every 500 to 1,000 pumping hours or annually, whichever comes first. It is crucial to regularly inspect the seals to detect any signs of wear or damage. Common indications for replacement include leaks, excessive vibration, reduced pumping efficiency, or visible degradation of the seal material. If any of these issues are observed, it is important to promptly replace the seals to prevent further damage and ensure optimal pump functioning. It is important to note that certain pumps may require more frequent seal replacements due to their design or operating conditions. For example, high-pressure pumps or those used in abrasive environments may experience accelerated seal wear, necessitating more frequent replacements. To extend the lifespan of concrete pump seals, proper maintenance and care are essential. This involves regularly cleaning the pump and seals, ensuring proper lubrication, and following the manufacturer's guidelines for operation and maintenance. Additionally, using high-quality seals and regularly inspecting them for wear can help prolong their longevity. Ultimately, determining the replacement frequency of concrete pump seals involves a combination of regular inspections, adherence to maintenance practices, and consideration of specific operating conditions.

- Q: Can I repair concrete pump spare parts instead of replacing them?

- Yes, it is possible to repair concrete pump spare parts instead of replacing them in some cases. However, the feasibility of repair depends on the extent of damage and the specific part in question. It is recommended to consult with a professional or the manufacturer to determine if repair is a viable option or if replacement is necessary for optimal performance and safety.

- Q: How do I properly adjust and control flow rates in concrete pump spare parts?

- To properly adjust and control flow rates in concrete pump spare parts, you should start by examining the pump's manual and understanding its specific settings and controls. It's important to ensure that all valves and levers are in the correct position and functioning properly. Additionally, you can adjust the flow rate by manipulating the stroke length and speed of the pump. Experimenting with these settings while monitoring the flow rate will help you achieve the desired results. Regular maintenance and cleaning of the pump parts are also crucial to ensure smooth flow control.

- Q: Can I reuse old concrete pump spare parts?

- Yes, old concrete pump spare parts can be reused as long as they are in good condition and meet the required specifications for the pump. However, it is important to properly inspect and test the parts before reuse to ensure they will function safely and efficiently.

Send your message to us

Concrete Pump ELBOW R275, 45DGR Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords