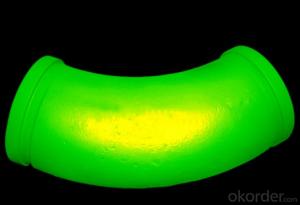

Concrete Pump Elbow R275, DN125MM Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Concrete Pump ELBOW R2751. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275 widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275 according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: Are there any safety considerations when using concrete pump spare parts?

- Yes, there are several safety considerations when using concrete pump spare parts. Firstly, it is important to ensure that the spare parts are of high quality and meet the necessary safety standards. Using substandard or faulty spare parts can increase the risk of accidents and malfunctions. Additionally, proper training and knowledge of the equipment and spare parts are crucial to ensure safe operation. Regular inspection and maintenance of the spare parts are also essential to prevent any potential hazards. Lastly, following all safety guidelines and protocols provided by the manufacturer is necessary to minimize the risk of injuries or accidents while using concrete pump spare parts.

- Q: Are there any specific recommendations for the inspection and testing of concrete pump spare parts?

- Concrete pump spare parts come with specific recommendations for inspection and testing. To begin with, it is essential to visually examine the spare parts for any damage, such as cracks, dents, or excessive wear. Carefully inspect the parts for any irregularities or abnormalities. Next, it is advised to conduct non-destructive testing (NDT) to guarantee the integrity and quality of the spare parts. NDT methods like ultrasonic testing, magnetic particle testing, or dye penetrant testing can be utilized to identify any hidden flaws or defects in the parts. These tests are beneficial in detecting potential issues that might impact the performance or safety of the concrete pump. Additionally, it is recommended to verify the dimensions and tolerances of the spare parts to ensure they adhere to the manufacturer's specifications. Precision measuring tools can be employed to compare the measurements with the required specifications. Any deviations should be documented and addressed accordingly. Furthermore, functional testing should be carried out to ensure that the spare parts are functioning as intended. This involves installing the parts in the concrete pump and conducting various tests to verify their functionality and performance. For instance, the pump's flow rate, pressure, and efficiency can be tested to ensure optimal performance. Lastly, it is of utmost importance to adhere to the manufacturer's guidelines and recommendations for inspecting and testing concrete pump spare parts. These guidelines provide specific instructions and procedures for accurately and safely inspecting and testing each type of spare part. It is crucial to consult the manufacturer's documentation and seek professional advice if necessary.

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts. These guidelines ensure proper installation and optimal performance of the equipment. Here are some key guidelines to consider: 1. Inspection: Before installation, thoroughly inspect the wear plates or wear rings for any damage or defects. Any damaged or worn-out parts should be replaced to ensure efficient operation. 2. Cleanliness: Ensure that the concrete pump and all related components are clean and free from debris or contaminants. This will help prevent premature wear and extend the lifespan of the wear plates or wear rings. 3. Lubrication: Apply a suitable lubricant to the wear plates or wear rings before installation. This will help reduce friction and extend the service life of these components. 4. Alignment: Proper alignment is crucial for the effective functioning of wear plates or wear rings. Ensure that the plates or rings are aligned correctly and securely fixed in place. Misalignment can cause premature wear and damage to the equipment. 5. Tightening: Use the recommended torque specifications to tighten the bolts or fasteners that secure the wear plates or wear rings. Over-tightening or under-tightening can lead to improper functioning or damage to the equipment. 6. Regular Maintenance: Implement a regular maintenance schedule to inspect and replace worn-out wear plates or wear rings. Regular maintenance will help identify and address any issues before they lead to major breakdowns or costly repairs. It is important to consult the manufacturer's guidelines and follow their specific instructions for the installation of wear plates or wear rings in concrete pump spare parts. Adhering to these guidelines will ensure optimal performance and longevity of the equipment.

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage and maintain the pressure within the pumping system. Concrete pumps are used to transfer liquid concrete from one location to another, typically from a mixer truck to a construction site. These pumps operate under high pressure to ensure the concrete flows smoothly through the pipeline. A concrete pump seal is a vital component that helps maintain the integrity of the pumping system. It is usually made of durable materials such as rubber or polyurethane, designed to withstand the high pressures and abrasive nature of concrete. The seal is located at the connection points between various sections of the pipeline, including the pump, pipeline joints, and hose connections. The primary function of the seal is to prevent concrete from leaking out of the system. Concrete is a viscous material, and any leakage can cause significant problems, such as a decrease in pumping efficiency, wastage of concrete, and potential damage to the surrounding environment. The seal ensures that the pumping system remains leak-free, allowing for efficient and continuous concrete transfer. Additionally, the seal helps maintain the required pressure within the pumping system. Concrete pumps rely on consistent pressure to ensure the concrete is delivered smoothly and evenly. Any pressure loss due to leakage can lead to uneven flow or blockages in the pipeline, affecting the overall performance of the pump. By sealing the connection points, the seal helps maintain the desired pressure, ensuring the concrete is pumped efficiently. Overall, the role of a concrete pump seal is to prevent leakage, maintain pressure, and ensure the smooth and efficient transfer of concrete from the source to the destination. It is an essential component that contributes to the overall effectiveness and reliability of concrete pumping operations.

- Q: What is the purpose of a concrete pump carbide wear plate?

- The purpose of a concrete pump carbide wear plate is to provide a durable and long-lasting surface for the concrete pump to transfer the concrete from the hopper to the desired location. Concrete pumps operate by using a piston system to push the concrete through the pump and into the delivery line. During this process, the wear plate serves as a protective barrier against the abrasive nature of the concrete. Concrete is a mixture of various materials, including sand, gravel, cement, and water. As it is pushed through the pump, the abrasive particles in the concrete can cause significant damage to the internal components of the pump, leading to decreased efficiency and increased maintenance costs. The carbide wear plate is specifically designed to withstand the high pressures and abrasive forces encountered during the concrete pumping process. Made from a strong and durable material called carbide, the wear plate provides a resistant surface that minimizes wear and tear on the pump's internal components. By using a concrete pump carbide wear plate, contractors and construction professionals can ensure that their concrete pumps operate efficiently and effectively, with minimal downtime for repairs. This not only saves time and money but also ensures that the concrete is delivered smoothly and consistently to the desired location, resulting in high-quality construction projects.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- The common challenges in sourcing spare parts for stationary concrete pumps include limited availability, long lead times, high costs, and compatibility issues with older models. Additionally, the need for genuine parts from reputable manufacturers is crucial to ensure optimal performance and avoid potential breakdowns or safety risks.

- Q: What are the different types of concrete pump clamps?

- There are several different types of concrete pump clamps available, each designed to serve a specific purpose and fit different pump sizes. Some of the common types include: 1. Snap clamps: These clamps are easy to install and remove as they utilize a snap mechanism. They are typically used for securing smaller diameter hoses and pipes. 2. Bolt clamps: Bolt clamps are more sturdy and provide a stronger grip. They consist of a metal band with bolts that can be tightened to secure the hose or pipe in place. These clamps are commonly used for larger diameter hoses and pipes. 3. Wedge clamps: Wedge clamps use a wedge device to hold the hose or pipe firmly in place. These clamps are often used in high-pressure applications or when working with heavy-duty pumps. 4. Quick-release clamps: Quick-release clamps are designed for easy and fast installation and removal. They feature a lever or latch that allows for quick release and adjustment. These clamps are commonly used in situations where frequent hose or pipe changes are required. 5. Flanged clamps: Flanged clamps are specifically designed to secure pipes with flanges. They provide a tight and secure connection between the pump and the pipe, preventing leaks or disconnections. It's important to choose the right type of concrete pump clamp based on the specific requirements of your project, including the pump size, hose or pipe diameter, and the expected pressure. Consulting with a professional or supplier can help ensure you select the appropriate clamp for your needs.

- Q: How do I maintain the performance of concrete pump spare parts in extreme weather conditions?

- Maintaining the performance of concrete pump spare parts in extreme weather conditions is crucial to ensure the efficiency and longevity of your equipment. Here are some tips to help you maintain the performance of concrete pump spare parts in extreme weather conditions: 1. Regular inspection: Conduct regular inspections of your concrete pump spare parts to identify any signs of wear and tear. Extreme weather conditions can accelerate the deterioration of parts, so it is important to catch any potential issues early on. 2. Keep parts clean: Extreme weather conditions such as rain, snow, or excessive heat can lead to the accumulation of dirt, debris, or other contaminants on your spare parts. It is essential to clean the parts regularly to prevent any clogging or damage. 3. Proper lubrication: Lubrication is crucial for the smooth functioning of concrete pump spare parts. In extreme weather conditions, it is recommended to use lubricants specifically designed for such conditions. These lubricants should have high viscosity and resistance to temperature fluctuations. 4. Protect from direct exposure: Extreme weather conditions, such as extreme heat or freezing temperatures, can directly impact the performance of concrete pump spare parts. It is essential to protect the parts from direct exposure to these conditions by utilizing covers or enclosures. 5. Store spare parts correctly: When not in use, spare parts should be stored in a dry and temperature-controlled environment. Extreme weather conditions can cause parts to expand or contract, leading to potential damage. Storing spare parts in a controlled environment will help maintain their integrity and performance. 6. Timely replacement: Constant monitoring and timely replacement of worn-out parts are crucial to maintaining the performance of concrete pump spare parts. Extreme weather conditions can accelerate the wear and tear process, so it is important to have a proactive approach towards replacement. 7. Consult the manufacturer: If you are unsure about the specific requirements for maintaining concrete pump spare parts in extreme weather conditions, it is always best to consult the manufacturer. They can provide you with expert advice and guidance on how to ensure optimal performance in such conditions. By following these tips, you can effectively maintain the performance of concrete pump spare parts in extreme weather conditions, ensuring the smooth and efficient operation of your equipment.

- Q: Are there any online resources or manuals available for concrete pump spare parts?

- Yes, there are several online resources and manuals available for concrete pump spare parts. Many manufacturers and suppliers have websites where you can find detailed information about various spare parts, their specifications, and ordering details. Additionally, there are online marketplaces and forums dedicated to construction equipment, where you can find comprehensive catalogs, user manuals, and even discussion threads related to concrete pump spare parts.

Send your message to us

Concrete Pump Elbow R275, DN125MM Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords