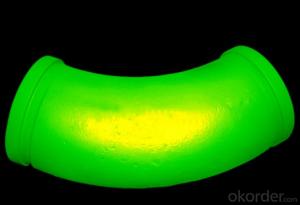

Concrete Pump ELBOW R275, 45DGR DN125MM Grey

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Concrete Pump ELBOW R275, 45DGR DN125MM Grey with High Quality

1. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275, 45DGR DN125MM Grey widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275, 45DGR DN125MM Grey put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: Are there any special tools required for replacing concrete pump spare parts?

- Yes, there are some special tools required for replacing concrete pump spare parts. These tools may vary depending on the specific part being replaced, but some common tools include wrenches, sockets, hydraulic jacks, cranes or hoists, and torque wrenches. Additionally, some specific parts may require specialized tools such as concrete saws, chisels, or drills for removing old parts or preparing surfaces for installation. It is important to consult the manufacturer's guidelines or seek professional advice to ensure the correct tools are used for replacing concrete pump spare parts.

- Q: How do I determine the correct temperature ratings for concrete pump spare parts?

- Determining the appropriate temperature ratings for spare parts of your concrete pump requires careful consideration of the specific requirements and specifications of your pump system. To assist you in this process, the following steps can be taken: 1. Review the manufacturer's documentation: Begin by examining the technical specifications provided by the manufacturer of your concrete pump system. The manufacturer should furnish temperature ratings for various components and spare parts. Look for information regarding temperature limits, recommended operating temperature ranges, as well as any specific guidelines or restrictions pertaining to temperature. 2. Identify crucial components: Identify the key components of your concrete pump system that may be impacted by temperature, such as hoses, seals, gaskets, valves, and electrical components. These components may possess different temperature ratings based on the materials used and their specific design. 3. Evaluate application conditions: Assess the operating conditions of your concrete pump system to determine the potential temperature extremes it may encounter. Factors such as ambient temperature, concrete mix temperature, and the presence of external heat sources (e.g., hot weather or neighboring equipment) can influence the temperature of the system and its spare parts. 4. Verify compatibility: Ensure that the spare parts you are considering are compatible with the specific temperature range of your concrete pump system. Some components may possess different ratings based on factors like chemical compatibility, thermal expansion, and resistance to heat transfer. 5. Seek professional advice: If you are uncertain about the temperature ratings or require further clarification, it is advisable to consult professionals or experts in the field of concrete pump systems. They can offer specific recommendations based on their knowledge and experience. By following these steps and considering the manufacturer's guidelines and expert advice, you can determine the appropriate temperature ratings for spare parts of your concrete pump, thus guaranteeing the safe and efficient operation of your system.

- Q: Can I get spare parts for both concrete pumps with and without boom stabilizers?

- Yes, you can get spare parts for both concrete pumps with and without boom stabilizers.

- Q: What are the signs of a damaged concrete pump cylinder?

- Indicators of a damaged concrete pump cylinder are plentiful. One unmistakable sign is the leakage of hydraulic fluid from the cylinder. Should you observe any fluid dripping or pooling around the cylinder, it is possible that the seal or piston has been compromised. Unusual noises during operation can also suggest a damaged cylinder. If you detect any atypical clanking, grinding, or knocking sounds emanating from the pump, it may be a consequence of a damaged cylinder. This can stem from various issues, including a bent piston rod, worn-out bearings, or misalignment of components. A decrease in pumping efficiency is another common indication of a damaged cylinder. If you perceive that the pump is not effectively delivering concrete as it once did, it is likely due to a damaged cylinder. This can lead to diminished output, slower pumping speed, or even a complete failure to pump concrete. Performing a visual inspection can aid in identifying signs of a damaged cylinder. Observe the cylinder body for visible cracks, dents, or deformations. Additionally, examine the piston or piston rod for signs of excessive wear, such as scratches or grooves. Lastly, frequent breakdowns or malfunctions with the concrete pump can be an indication of a damaged cylinder. Consistent repairs or failures may be a consequence of underlying issues with the cylinder, such as fatigue, corrosion, or improper maintenance. Should you notice any of these signs, it is crucial to promptly address the issue. Continuing to operate a concrete pump with a damaged cylinder can result in further damage, increased repair costs, and potential safety hazards. It is recommended to consult a professional technician or the manufacturer to assess and repair the damaged cylinder.

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific maintenance procedures to ensure effective functioning and longevity. It is crucial to regularly maintain them. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Minimize friction and wear by regularly lubricating moving parts like pistons, cylinders, and valves. This helps maintain smooth operation and prevent premature failure. 2. Cleaning: Regularly clean spare parts to remove debris, dirt, or concrete buildup. Accumulated material can hinder performance and cause damage. Use appropriate cleaning agents and tools for thorough cleaning. 3. Inspection: Routinely inspect spare parts for signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or abnormal functioning. Promptly detect issues for timely repairs or replacements. 4. Replacement: Immediately replace worn-out or damaged spare parts. Delaying replacements can lead to further damage and costly repairs. Follow the manufacturer's recommendations for part lifespan and replacement. 5. Calibration: Correctly calibrate spare parts to maintain optimum performance. Adjust pressure settings, flow rates, and other parameters according to manufacturer's guidelines. Regular calibration ensures accurate and efficient concrete pumping. 6. Storage: Properly store spare parts to prevent damage from environmental factors. Keep them in a clean, dry place away from direct sunlight or extreme temperatures. Follow any specific storage instructions from the manufacturer. 7. Training: Train operators and maintenance personnel on proper handling, maintenance, and repair of spare parts. This ensures correct procedures are followed, minimizing damage risk and maximizing equipment lifespan. Following these maintenance procedures will keep concrete pump spare parts in optimal condition, enhancing performance, reliability, and longevity.

- Q: What is the function of a concrete pump control lever?

- The function of a concrete pump control lever is to regulate the flow and direction of concrete being pumped, allowing the operator to precisely control the placement and distribution of concrete during construction projects.

- Q: How often should a concrete pump wear plate be replaced?

- The frequency at which a concrete pump wear plate should be replaced depends on several factors, including the type of concrete being pumped, the volume of concrete being pumped, and the quality and maintenance of the pump itself. However, as a general guideline, it is recommended to inspect the wear plate regularly, especially after each concrete pour, to assess its condition. Typically, a concrete pump wear plate should be replaced when it becomes significantly worn or damaged. Signs of wear may include excessive grooves, cracks, or holes on the surface of the plate. This can affect the efficiency and performance of the pump, leading to decreased output and potential leaks. In high-intensity pumping operations or when abrasive materials are used, the wear plate may wear out faster and need to be replaced more frequently. On the other hand, if the pump is used less frequently or with less abrasive materials, the wear plate may last longer. It is important to note that regular maintenance and proper cleaning of the wear plate can extend its lifespan. This includes removing any hardened concrete residue and ensuring a smooth and clean surface. Lubricating the plate with suitable products can also help reduce friction and wear. Ultimately, it is recommended to consult the manufacturer's guidelines and seek advice from experienced professionals to determine the optimal replacement schedule for a concrete pump wear plate, considering the specific conditions and usage of the pump.

- Q: What is the function of a concrete pump remote control?

- A concrete pump remote control serves as a tool to operate and control the functions of a concrete pump from a distance. It allows the operator to manipulate various aspects of the pump's operation, such as starting and stopping the pumping process, adjusting the speed and direction of the pump, and controlling the placement and flow of the concrete. By providing remote control capabilities, it eliminates the need for the operator to be physically close to the pump, allowing for safer and more efficient operation. Additionally, the remote control often includes features such as emergency stop buttons, diagnostics, and data logging capabilities, which further enhance the functionality and reliability of the concrete pump. Overall, the function of a concrete pump remote control is to provide convenience, precision, and safety in the operation of concrete pumping equipment.

- Q: Can I get spare parts for both concrete pumps with and without water tanks?

- Indeed, spare parts are readily accessible for both concrete pumps equipped with water tanks and those without. A multitude of manufacturers and suppliers present an extensive array of spare parts for concrete pumps, encompassing diverse models with or without water tanks. These spare parts serve the purpose of regular maintenance, repairs, or replacements for a variety of components, including hoses, pipes, valves, cylinders, seals, and other essential elements. Prioritizing the acquisition of appropriate spare parts tailored to your specific concrete pump model is crucial to guarantee compatibility and achieve optimal performance.

- Q: What is the function of a concrete pump control box?

- The concrete pump control box is a vital component of a concrete pump system, responsible for managing and controlling the operation of the pump to ensure a safe and efficient pumping process. By utilizing the control box, the operator can initiate, halt, and adjust the pumping speed of the concrete pump. Equipped with various control switches, knobs, and buttons, the control box facilitates control over different aspects of the pumping process. One of the key roles of the control box is to monitor the pressure and flow of the pumped concrete. This data is essential in guaranteeing that the concrete is pumped at the desired rate and consistency. Furthermore, the control box promptly notifies the operator of any irregularities or problems in the pumping system, such as clogs or blockages. Moreover, the control box may incorporate features like emergency stop buttons and safety interlocks to ensure the safety of both the operator and the equipment. Indicators and alarms may also be included to provide visual and audible cues regarding the pump's status and any potential issues that may arise. To summarize, the concrete pump control box's purpose is to equip the operator with the necessary controls and information to operate the concrete pump safely and efficiently. It ensures appropriate monitoring, control, and safety of the pumping process, ultimately leading to successful concrete placement.

Send your message to us

Concrete Pump ELBOW R275, 45DGR DN125MM Grey

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords