3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

1. Structure of 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

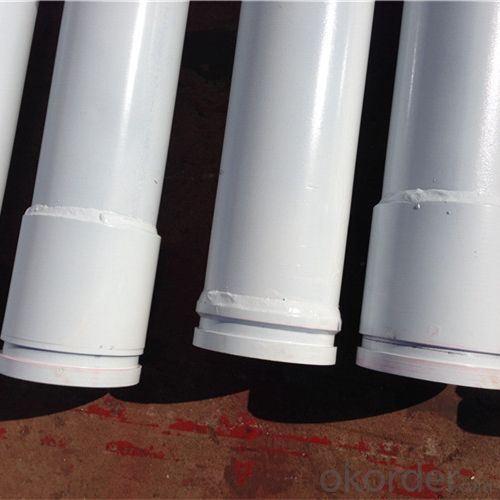

3. 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm Images

4. 3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q: Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Concrete pump spare parts can undergo pre-assembly and pre-testing prior to installation. This allows for quality control measures to be implemented before the actual installation takes place, ensuring that any defects or issues with the parts can be identified and resolved before they are put into the concrete pump. Furthermore, pre-testing the spare parts guarantees their functionality and compatibility with the pump system, enabling any necessary adjustments or modifications to be made in advance. By engaging in these practices, the risk of complications during the installation process is reduced, resulting in a smooth and efficient operation of the pump system.

- Q: Are there any specific brands or manufacturers that are recommended for concrete pump spare parts?

- Concrete pump spare parts are highly recommended from various reputable brands and manufacturers. Putzmeister, Schwing, Sany, and Zoomlion are among the top brands in the industry that offer high-quality, reliable, and durable products. Their extensive range of spare parts caters to different models of concrete pumps, ensuring customers can easily obtain the specific parts they require. Moreover, these brands have established a strong market presence and possess a wide network of dealers and distributors worldwide, facilitating convenient access to their spare parts. To ensure the longevity and optimal performance of your concrete pump, it is always advisable to select spare parts from renowned brands and manufacturers.

- Q: How can one identify the correct type of rubber seals or gaskets for concrete pump spare parts?

- To identify the correct type of rubber seals or gaskets for concrete pump spare parts, one should consider several factors. Firstly, it is important to know the specific model and make of the concrete pump to ensure compatibility. Additionally, one should evaluate the application requirements, such as the pressure and temperature conditions the seals or gaskets will be exposed to. Considering the material compatibility with the fluids or chemicals being pumped is also crucial. Consulting the manufacturer's specifications or seeking expert advice can provide further guidance in identifying the correct type of rubber seals or gaskets for concrete pump spare parts.

- Q: Can I get spare parts for both concrete pumps with and without emergency stop systems?

- Spare parts for both concrete pumps with and without emergency stop systems can be obtained. A wide range of compatible spare parts are offered by most concrete pump manufacturers and suppliers. These spare parts consist of hoses, pipes, valves, seals, and other essential components that may require replacement due to wear and tear or damage. Regardless of whether your concrete pump is equipped with an emergency stop system or not, you should be able to find the necessary spare parts to maintain smooth operation. However, it is important to note that the availability of specific spare parts may vary depending on the brand, model, and age of your concrete pump. To ensure that you obtain the correct spare parts, it is advisable to consult the manufacturer or supplier of your concrete pump. They can provide you with a comprehensive list of spare parts and help you select the appropriate ones for your specific pump. Additionally, they may also offer technical support and troubleshooting assistance for any issues related to your concrete pump.

- Q: What is the function of a concrete pump hopper grate pin?

- The function of a concrete pump hopper grate pin is to secure the hopper grate in place and prevent it from dislodging or shifting during the concrete pumping process. The pin acts as a mechanism to lock the grate into position, ensuring that it remains stable and does not pose any safety risks or cause disruption to the pumping operation. Additionally, the pin allows for easy removal and replacement of the grate when necessary, facilitating maintenance and cleaning of the hopper. Overall, the concrete pump hopper grate pin plays a crucial role in maintaining the integrity and efficiency of the concrete pumping equipment.

- Q: How can a faulty hydraulic filter affect the pump's hydraulic system?

- The pump's hydraulic system can experience several negative effects when a hydraulic filter is faulty. The main purpose of a hydraulic filter is to eliminate contaminants like dirt, debris, and other particles from the hydraulic fluid, guaranteeing that the fluid is pure and free from impurities. When the filter is faulty or blocked, it fails to effectively filter the fluid, resulting in various issues. To begin with, the presence of contaminants in the hydraulic fluid can lead to heightened wear and tear on the pump's components. The particles can cause abrasion and damage to the pump's moving parts, including the pistons, valves, and seals. This can lead to reduced efficiency and performance of the pump, as well as potential leaks or failures. Moreover, a faulty hydraulic filter can induce a decrease in the overall system pressure. As the contaminants accumulate in the fluid, they can hinder the flow of hydraulic fluid, creating increased resistance within the system. Consequently, this can cause a drop in pressure, resulting in reduced hydraulic power and slower operation of the pump. Additionally, a clogged filter can also result in increased heat generation within the hydraulic system. The presence of contaminants restricts the flow of fluid, causing the pump to work harder and generate more heat. This can lead to overheating of the hydraulic fluid, which can further damage the pump and other components of the system. Overheating can also cause the hydraulic fluid to deteriorate, reducing its lubricating properties and potentially causing additional wear and damage. In conclusion, a faulty hydraulic filter can impact the pump's hydraulic system by causing increased wear and tear on components, reduced system pressure, slower operation, increased heat generation, and potential fluid degradation. It is crucial to regularly maintain the hydraulic system, including timely replacement of hydraulic filters, to ensure the efficient and reliable functioning of the pump.

- Q: How often should concrete pump hydraulic oil coolers be inspected and maintained?

- Concrete pump hydraulic oil coolers should be inspected and maintained regularly, ideally on a monthly basis or as recommended by the manufacturer. Regular inspections and maintenance ensure optimal performance and help identify any potential issues or damage that may affect the efficiency and lifespan of the equipment.

- Q: How often should hopper pins be inspected or replaced in a concrete pump?

- Hopper pins in a concrete pump should be inspected and replaced on a regular basis to ensure the safe and efficient operation of the equipment. The frequency of inspection and replacement depends on several factors, including the usage of the concrete pump and the condition of the hopper pins. As a general guideline, hopper pins should be inspected at least once every three to six months, or after every 400 to 600 hours of operation. However, it is important to note that this timeframe can vary based on the intensity and volume of concrete pumping activities. During the inspection, the hopper pins should be carefully examined for signs of wear, damage, or deformation. Any pins that show significant signs of wear, such as cracks, elongation, or excessive corrosion, should be immediately replaced to prevent potential accidents or equipment failure. Regular inspection and replacement of hopper pins are crucial for maintaining the structural integrity of the concrete pump and ensuring the safety of both the operators and the surrounding environment. It is recommended to consult the manufacturer's guidelines or seek professional advice to determine the specific inspection and replacement schedule based on the make and model of the concrete pump.

- Q: How often should hopper grate levers be inspected or replaced in a concrete pump?

- To ensure the proper functioning and prevent potential issues, it is necessary to regularly inspect the hopper grate levers in a concrete pump. The frequency of inspections may vary based on factors such as usage intensity, material being pumped, and operating conditions. However, a general recommendation is to conduct inspections at least once every six months or after every 500 hours of operation. During the inspection, carefully examine the hopper grate levers for signs of wear, damage, or misalignment. If any issues are identified, it is crucial to promptly replace the levers to prevent further damage to the hopper grate system or potential safety hazards. To ensure optimal performance and durability, it is essential to utilize high-quality replacement parts specifically designed for the concrete pump model. By conducting regular inspections and timely replacements of hopper grate levers, the efficiency and reliability of the concrete pump can be maintained, minimizing downtime and expensive repairs.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- It is advisable to conduct regular inspections on hydraulic cylinders in a concrete pump, ideally every 500 hours of operation or at least once a year, whichever occurs first. However, it is important to acknowledge that the frequency of inspections may differ based on the specific conditions and usage of the concrete pump. During these inspections, qualified technicians should thoroughly assess the hydraulic cylinders for any indications of wear, damage, or leaks. Additionally, they should verify the alignment, piston rods, seals, and other components to ensure proper functionality. If any issues are discovered, such as excessive wear or leaks, it is recommended to promptly replace the hydraulic cylinders to prevent further damage and maintain optimal performance. The regular inspections and timely replacements of hydraulic cylinders are vital for guaranteeing the safety, efficiency, and longevity of a concrete pump. Neglecting proper maintenance can result in expensive repairs, decreased productivity, and even accidents. Therefore, it is crucial to adhere to the manufacturer's guidelines and seek advice from professionals to determine the appropriate intervals for inspecting and replacing hydraulic cylinders in a concrete pump.

Send your message to us

3M Seamless Delivery Pipe for Concrete Pump Thickness 4.2mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords