Colored Aluminum Sheets Minnesota - PVDF Coated Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

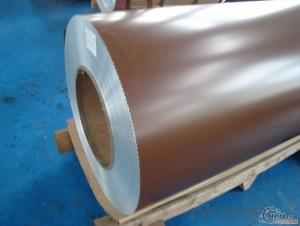

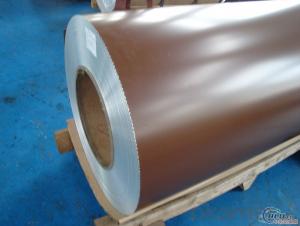

1.Structure of PVDF Coated Aluminium Coils for Outer Decoration

PVDF Coated aluminium coils for Outer Decoration are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of PVDF Coated Aluminium Coils for Outer Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating Thickness | Thickness | Width |

| AA1100 | H14 | 20-25 MICRONS | 0.2MM-2MM | 1000MM-1500MM |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the different methods of surface coloring aluminum sheets?

- Aluminum sheets can be colored using various methods, each with its own strengths and limitations. Let's explore some of the commonly used techniques: 1. Anodizing: Anodizing is a favored method for coloring aluminum sheets. It entails creating a controlled oxide layer on the surface of the aluminum through an electrochemical process. This layer can be dyed in different colors, resulting in a resilient and long-lasting finish. Anodized aluminum is resistant to corrosion, UV rays, and scratches, making it an excellent choice for outdoor applications. 2. Powder coating: Powder coating is another popular technique for coloring aluminum sheets. It involves applying a dry powder coating to the sheet's surface, which is then cured in an oven. The powder melts and forms a protective layer that adheres to the aluminum. Powder coating offers a wide range of colors and finishes, and it provides exceptional durability, fade resistance, and scratch protection. 3. Painting: Painting is a traditional method for coloring aluminum sheets. It requires applying a liquid paint to the surface, which subsequently dries and forms a protective layer. Painting offers a vast array of color options and can achieve various finishes, such as matte, gloss, or metallic. However, painted aluminum sheets may require additional protective coatings to enhance durability and fade resistance. 4. Cladding: Cladding is a technique that involves applying a thin layer of colored material, such as stainless steel, copper, or composite panels, onto the aluminum sheet's surface. This method allows for a wide range of colors and finishes, while also providing extra protection. Cladding can be utilized to achieve a unique aesthetic or enhance the durability of the aluminum sheet. 5. Dye sublimation: Dye sublimation is a specialized method of coloring aluminum sheets, which employs heat and pressure to transfer designs or images onto the surface. This process enables high-resolution prints and vibrant colors, making it particularly suitable for decorative and signage applications. Each method of coloring aluminum sheets has its own advantages and considerations, such as durability, aesthetics, cost, and application requirements. It is crucial to thoroughly assess these factors when determining the most suitable method for a specific project.

- Q: How do aluminum sheets perform in terms of vibration damping?

- Aluminum sheets possess exceptional vibration damping properties, renowned for their ability to effectively absorb and dissipate vibrations. These sheets, with their high density and stiffness, are capable of reducing both the amplitude and duration of vibrations. Consequently, aluminum sheets are deemed highly suitable for applications demanding vibration control, particularly in the aerospace and automotive sectors. Moreover, the lightweight nature of aluminum enables effortless installation and maneuverability, rendering it the preferred choice for vibration damping solutions.

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a material for exterior walls in construction.

- <p>Aluminum sheets for exterior walls offer several advantages, including durability, low maintenance, and resistance to corrosion and weathering. They are lightweight, which can reduce the load on structures, and are recyclable, contributing to sustainability. Additionally, aluminum sheets can be easily shaped and painted, offering design flexibility. However, they have some disadvantages, such as being a poor insulator, which may require additional insulation for energy efficiency. They can also dent or scratch easily and may require more frequent replacement due to their lower resistance to impacts compared to materials like stone or brick. Furthermore, while they reflect heat well, they can also conduct cold, potentially leading to issues in extreme temperature conditions.</p>

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- choose the 8-10% of the thickness for two-sided gaps.

- Q: What are the common aluminum sheets and the best ones?

- That depends on what you are doing, and commonly used on 3003 and 5052, the performance is better to use 6061

- Q: What is the lifespan of the aluminum sheets?

- The durability and longevity of aluminum sheets can differ due to various factors, including the aluminum's quality, the usage environment, and the level of maintenance provided. Despite this, aluminum sheets are renowned for their long-lasting nature. On average, these sheets endure for approximately 20 to 30 years, but by ensuring proper care and maintenance, their lifespan can surpass this estimate. To extend the longevity of aluminum sheets, it is beneficial to regularly clean them, shield them from severe weather conditions, and prevent exposure to corrosive substances.

- Q: Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- Length: + 1mmWidth: + 0.5mmThickness: + 0.02mm, that is, 2 filaments

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: What are the different types of protective films available for aluminum sheets?

- There exists a variety of protective films for aluminum sheets, each offering distinct features and advantages. Some commonly used types include: 1. Polyethylene (PE) film: PE film is a favored option for safeguarding aluminum sheets due to its versatility and cost-effectiveness. It serves as a temporary shield against scratches, dust, dirt, and moisture during storage, transportation, and fabrication processes. PE film can be effortlessly applied and removed without leaving residue or causing damage to the aluminum sheet's surface. 2. Polyvinyl Chloride (PVC) film: PVC film is another popular protective film for aluminum sheets. It provides excellent protection against scratches, abrasions, and UV rays. Known for its durability, PVC film is suitable for long-term applications. It is available in different thicknesses and can be customized to meet specific requirements. 3. Polyolefin film: Polyolefin film is a type of shrink film that ensures comprehensive protection for aluminum sheets. It exhibits high resistance against punctures, tears, and moisture. By heat-shrinking onto the aluminum surface, polyolefin film creates a secure seal, preventing any damage during handling, storage, or transit. 4. Polyester film: Polyester film is a high-performance protective film that offers exceptional resistance against chemicals, solvents, and extreme temperatures. It serves as an excellent barrier against moisture, preventing corrosion and oxidation of the aluminum sheet. Polyester film is commonly utilized in demanding applications where maximum protection is required. 5. Adhesive-backed film: Adhesive-backed films are self-adhesive protective films that can be easily applied and firmly bonded to aluminum sheets. They provide a temporary protective layer against scratches, stains, and other surface damages. Available with different adhesive strengths, adhesive-backed films can be removed effortlessly without leaving residue or causing harm to the aluminum surface. It is crucial to choose the appropriate type of protective film based on the specific requirements and conditions in which the aluminum sheets will be utilized.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport furniture. Secondly, aluminum is resistant to corrosion, ensuring the durability and longevity of furniture products. Additionally, aluminum sheets can be easily molded and shaped into various designs, allowing for creative and unique furniture pieces. Lastly, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for the furniture industry.

Send your message to us

Colored Aluminum Sheets Minnesota - PVDF Coated Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords