Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Coil PVDF painting for Outer Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coated Aluminium Coil PVDF painting for Outer Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Coil PVDF painting for Outer Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

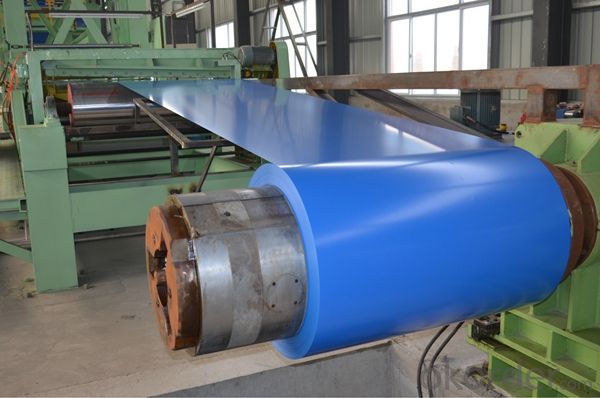

5. Image of Color Coated Aluminium Coil PVDF painting for Outer Doors

6. Package and shipping of Color Coated Aluminium Coil PVDF painting for Outer Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used for gutter systems?

- Yes, aluminum coils can be used for gutter systems. Aluminum is a popular choice for gutters due to its lightweight nature, durability, and resistance to rust and corrosion. It is also easy to shape and install, making it a suitable material for gutter systems.

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils have a wide range of potential applications due to their unique properties and advantages. Here are some of the key potential applications: 1. Architectural: Coil-anodized aluminum coils can be used in architectural applications such as cladding, roofing, and facades. The anodized coating provides enhanced durability, weather resistance, and color stability, making it suitable for exterior use in different climates. The coils can also be shaped and formed into various architectural elements, offering design flexibility. 2. Transportation: The lightweight nature of coil-anodized aluminum makes it ideal for transportation applications. It can be used for manufacturing parts and components in automotive, aerospace, and marine industries. The anodized coating enhances the corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils can be utilized in electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications requiring high conductivity and insulation. It can be used for manufacturing components like heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors obtained through coil-anodizing make it an ideal material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, making it suitable for both indoor and outdoor applications. It allows for the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be used in the manufacturing of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can find applications in various industrial sectors. The anodized coating provides enhanced corrosion resistance, which is beneficial in industries like chemical processing, food processing, and pharmaceuticals. It can be used for manufacturing tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be used in manufacturing solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. Overall, the potential applications of coil-anodized aluminum coils are extensive and diverse, ranging from architectural and transportation to electronics, signage, furniture, industrial, and energy sectors. The unique combination of lightweight, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum is a good conductor of electricity. If an object is completely encased in a conductor (forming a Faraday cage), the object will be shielded from radio waves. If the aluminum (or another conductor) covers only part of the object, radio waves may still reach it.

- Q: What are the bending and forming capabilities of aluminum coils?

- Due to its inherent properties as a malleable and ductile material, aluminum coils possess outstanding abilities in bending and forming. The high strength-to-weight ratio of aluminum allows for easy shaping and forming without compromising its structural integrity. In terms of bending, aluminum coils exhibit remarkable flexibility and can be bent into various shapes and angles without any risk of fracturing or cracking. This flexibility enables the formation of tight curves or gentle bends, making aluminum coils suitable for a wide range of applications. Particularly in industries such as construction, automotive, and aerospace, where curved or intricate shapes are often needed, the flexibility of aluminum coils proves to be highly advantageous. In the realm of forming, aluminum coils can be effortlessly manipulated into different forms, including flat sheets, tubes, or intricate profiles. This versatility makes aluminum coils highly sought after in industries that prioritize customization and design flexibility. Moreover, aluminum coils can undergo various forming processes, such as roll forming, stamping, and deep drawing, which allow for the transformation into different products with precise dimensions and tolerances. These exceptional forming capabilities make aluminum coils the preferred choice for manufacturing components like automotive body panels, roofing materials, heat exchangers, and structural elements. In conclusion, the exceptional bending and forming capabilities of aluminum coils make them an ideal choice for applications that demand flexibility, durability, and design versatility.

- Q: Can aluminum coils be used in the production of cookware?

- Yes, aluminum coils can be used in the production of cookware. Aluminum is a popular choice for cookware manufacturing due to its excellent heat conductivity, lightweight nature, and affordability. Aluminum coils can be shaped and formed into various cookware items such as pots, pans, and baking sheets, providing efficient and even heat distribution for cooking purposes.

- Q: This question asks for methods to determine whether an aluminum coil is safe for use.

- <p>To determine if your aluminum coil is safe to use, first, check for any visible signs of damage such as cracks, corrosion, or deformation. Ensure that the coil meets the required specifications for your application, including thickness, width, and alloy type. Verify the coil's compliance with safety standards and certifications relevant to your industry, such as ASTM or ISO standards. Test the coil's mechanical properties to ensure it has the necessary strength and ductility. Finally, consider the coil's history and usage; it should not have been exposed to extreme temperatures or corrosive environments that could compromise its integrity. Consulting with a materials expert or conducting a thorough inspection can provide further assurance of the coil's safety.</p>

- Q: Are aluminum coils suitable for construction applications?

- Indeed, construction applications can make good use of aluminum coils. Aluminum, a material known for its lightweight and durability, is extensively utilized in the construction sector. Aluminum coils find frequent application in roofing, siding, gutters, and other exterior uses owing to their resistance against corrosion and ability to withstand inclement weather conditions. Furthermore, their simple installation and maintenance procedures make them highly favored by contractors. Moreover, aluminum coils can be painted or coated to enhance their visual appeal and blend with the overall architectural design of a structure. Ultimately, aluminum coils offer a dependable and economical option for construction purposes.

- Q: How are aluminum coils stored and transported?

- Aluminum coils are typically stored and transported in various ways depending on their size and weight. They are commonly stored in warehouses or outdoor storage facilities, where they are organized and stacked horizontally on pallets or racks. To ensure their protection, coils are often covered with a protective material such as plastic or shrink wrap. When it comes to transportation, aluminum coils are usually loaded onto trucks, containers, or flatbed trailers for long-distance journeys. To prevent damage during transit, the coils are secured using straps, chains, or other fastening methods. Additionally, specialized equipment like coil racks or cradles can be used to provide extra support and stability. Overall, proper storage and transportation practices are crucial to maintain the integrity of aluminum coils and prevent any potential harm.

- Q: What are the weight savings achieved by using aluminum coils?

- Compared to materials like steel, significant weight savings can be achieved by using aluminum coils. Aluminum, a lightweight metal with a density approximately one-third that of steel, allows for greatly reduced overall weight when utilizing aluminum coils instead of steel coils. The benefits of weight savings attained through aluminum coil usage are numerous. In industries such as automotive and aerospace, reducing weight is crucial for enhancing fuel efficiency and increasing payload capacity. Lighter vehicles and aircraft require less energy for operation and can accommodate more passengers or cargo, resulting in cost savings, improved performance, and minimized environmental impact. Moreover, the weight savings obtained from aluminum coils can provide practical advantages in other applications as well. For instance, in HVAC systems, lighter coils facilitate easier installation and transportation, thereby reducing labor and logistics costs. The actual weight savings achieved by utilizing aluminum coils will vary depending on the specific application and design specifications. Nonetheless, it is widely acknowledged that aluminum coils offer a significant weight advantage over alternative materials. The actual weight savings can range from 30% to 70% or more, depending on the specific comparison being made. To summarize, the weight savings achieved through the use of aluminum coils can be substantial. This lightweight material offers numerous benefits in terms of fuel efficiency, payload capacity, performance, and cost savings. When prioritizing weight reduction, aluminum coils are an excellent choice for a wide range of industries and applications.

- Q: for purchasing aluminium are the grades to be mentioned

- If it is a product for work, yes engineers and purchasers specify the grades. If for hobby then it is up to you. Common extruded shapes (beams, tubes, angles) - 6061-T6 - 6063-T5 -T6 specifies tempering class. Actually both alloys come in various T4, T5, etc., the above are just two common combinations. 6061 is a little stronger, and T6 gets its strength up quite good. Beware that welded joints are weaker since heat removes the strength from tempering. Some common sheets - 6061 (strength) - 5052 (strength, welds better than 6xxx, good formability) - 5068 (some call it 'marine grade' for corrosion resistance) Sheets can come in many alloys.... you may get cheaper grades if you don't need one of these. (if you are casting - there's whole other system of grades.) The above are just common grades. For high strength requirement you may need a specific grade in the 7xxx family.

Send your message to us

Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords