Aluminum Coil Minnesota Painted Aluminium Sheets Plates for Wall Decorations

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of Painted Aluminium Sheets Plates for Wall Decorations

Alloy: 1050, 1100, 3003, 3005, 3105, etc

Thickness: 0.15mm~1mm

Painting Thickness: 5-10mic for back coating, 15-40mic for top coating

Paint Types: PVDF, PE, HDPE, LDPE, etc

Width: 900mm- 1950mm

Color: According to RAL colors or customer's samples

2. Application of Painted Aluminium Sheets Plates for Wall Decorations

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Painted Aluminium Sheets Plates for Wall Decorations

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

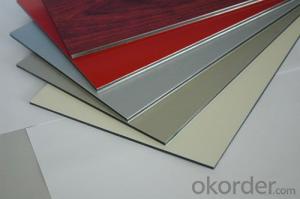

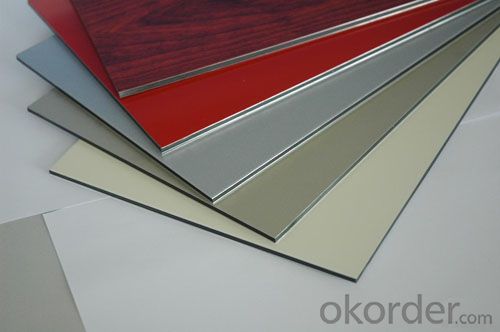

5. Image of Painted Aluminium Sheets Plates for Wall Decorations

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: Can aluminum coils be used in the production of household appliances?

- Yes, aluminum coils can be used in the production of household appliances. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications in appliances such as refrigerators, air conditioners, and cooktops. Additionally, aluminum coils offer excellent heat transfer properties, making them an ideal choice for enhancing energy efficiency in appliances.

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: What are the different types of surface finishes for decorative purposes?

- For decorative purposes, a variety of surface finishes are commonly used. These finishes can improve the appearance of a surface by adding texture, depth, and visual interest. Some of the most popular surface finishes for decorative purposes include: 1. Polished: Achieving a smooth and shiny surface, polished finishes create a reflective appearance. This glossy look is obtained by using abrasive materials to polish the surface. 2. Matte: Matte finishes have a flat and non-reflective surface. They are achieved by using sandpaper or other materials to create a smooth yet dull appearance. Matte finishes are often chosen for a more subtle and understated aesthetic. 3. Brushed: Creating a distinctive linear pattern, brushed finishes are achieved by brushing the surface with a wire brush or abrasive material. This finish is commonly used on metals like stainless steel, resulting in a textured and visually interesting appearance. 4. Textured: Textured finishes involve incorporating patterns or designs onto the surface through various techniques such as embossing, engraving, or applying a textured coating. These finishes add depth and dimension to a surface, creating a unique and visually appealing effect. 5. Antiqued: Designed to imitate the appearance of aged or weathered surfaces, antiqued finishes can be achieved through techniques like distressing, staining, or adding a patina. These finishes are often used to create a vintage or rustic look. 6. Metallic: Metallic finishes utilize metallic pigments or coatings to create a shiny and reflective appearance. This finish adds a touch of elegance and sophistication to a surface, making it a popular choice for decorative purposes. 7. High gloss: High gloss finishes have an extremely smooth and reflective surface, resembling a mirror-like effect. This finish is achieved by applying multiple layers of clear coat or lacquer and polishing the surface to a high shine. High gloss finishes are often chosen to create a modern and luxurious look. In conclusion, the selection of a surface finish for decorative purposes depends on the desired aesthetic and the type of material used. Each finish possesses unique qualities that can significantly enhance the overall visual appeal of a surface.

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: What is the maximum temperature that aluminum coils can withstand?

- The maximum temperature that aluminum coils can typically withstand is around 400-500 degrees Celsius (750-930 degrees Fahrenheit).

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- The cans also have paint on them so a pound of cans is a pound of aluminum and paint. A pound of pull tabs is all aluminum.

- Q: Is it possible to customize the dimensions of aluminum coils?

- Yes, it is possible to customize the dimensions of aluminum coils. Aluminum coils can be fabricated and cut to specific dimensions according to the requirements and specifications of the customer. The customization process involves precise cutting and shaping of the aluminum coil to achieve the desired dimensions. This allows for flexibility in various industries and applications where specific coil sizes are necessary. Customizing the dimensions of aluminum coils ensures that they can fit seamlessly into different production processes, machinery, or end-use applications.

- Q: Can aluminum coils be used in the production of aluminum windows?

- Yes, aluminum coils can be used in the production of aluminum windows. Coils are often used to create the frames and profiles of aluminum windows, as they can be easily shaped and formed into the desired configurations. This makes aluminum a popular material choice for window manufacturers due to its lightweight, durability, and corrosion-resistant properties.

- Q: What are the environmental benefits of using aluminum coils?

- Using aluminum coils offers numerous environmental advantages. Firstly, aluminum is an incredibly sustainable material due to its abundance on Earth and easy extraction from bauxite ore. Unlike other metals, aluminum can be recycled endlessly without losing its physical properties. Consequently, opting for aluminum coils assists in reducing the demand for extracting new resources and lessening the environmental impact of mining activities. Secondly, the lightweight nature of aluminum makes it more energy-efficient during transportation. Its low weight diminishes fuel consumption and greenhouse gas emissions associated with shipping and logistics. Moreover, aluminum coils can be easily molded and shaped, enabling efficient packaging and reducing the necessity for excess materials. Furthermore, aluminum possesses exceptional thermal conductivity properties. This means that aluminum coils can effectively transfer heat, leading to more energy-efficient heating and cooling systems. Incorporating aluminum coils into HVAC systems or heat exchangers reduces energy consumption, resulting in lower carbon dioxide emissions and a smaller carbon footprint. Additionally, aluminum boasts high resistance to corrosion and can withstand harsh weather conditions. This durability ensures a longer lifespan for aluminum coils, decreasing the need for frequent replacements and minimizing waste generation. Lastly, aluminum is non-toxic and poses no threat to human health or the environment. It does not release harmful substances or pollutants during production or use. Consequently, aluminum coils prove to be a safe and environmentally-friendly choice for various applications. To summarize, the environmental advantages of using aluminum coils encompass sustainability, recyclability, lightweight properties, energy efficiency, durability, and non-toxicity. By selecting aluminum coils, we contribute to resource conservation, energy savings, and a healthier planet.

- Q: Are aluminum coils suitable for architectural louvers?

- Indeed, architectural louvers can be constructed using aluminum coils as they possess remarkable corrosion resistance, a lightweight composition, and a commendable strength-to-weight ratio. The malleability and manipulability of aluminum coils grant them the ability to be effortlessly shaped and fabricated into diverse forms and dimensions, thereby rendering them exceptionally suitable for fashioning aesthetically appealing and practical louvers. Moreover, the robustness of aluminum guarantees that the louvers will endure severe weather conditions and retain their structural integrity for an extended period. In conclusion, aluminum coils serve as a dependable and adaptable material choice for architectural louvers.

Send your message to us

Aluminum Coil Minnesota Painted Aluminium Sheets Plates for Wall Decorations

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords