Aluminum Sheets in Missouri - Color Coated Aluminum Coils for Interior Decoration Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

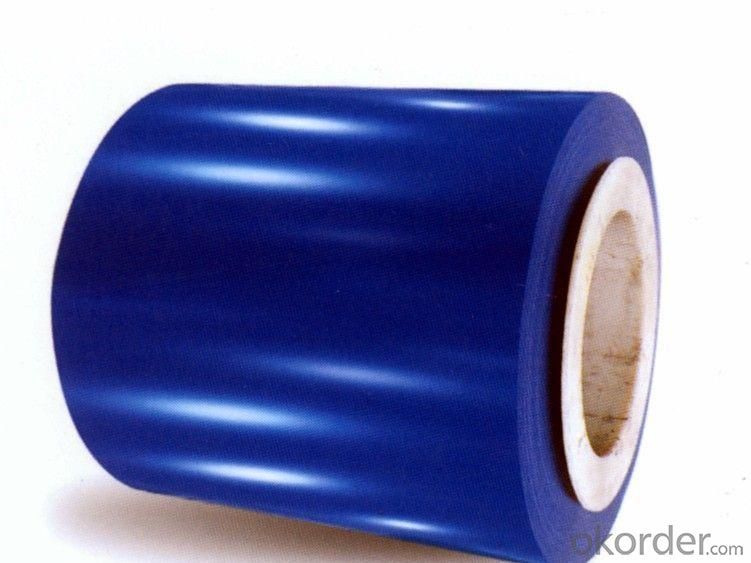

1.Structure of Color Coated Aluminium Coils for Inner Decoration Ceilling

Color Coated Aluminium Coils for Inner Decoration Ceilling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Inner Decoration Ceilling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- As Vincent noted, aluminium is an abundant element in the earth's crust. It occurs in all clay minerals. Its main ore, bauxite(a mixture of aluminium hydroxides) is still available in vast deposits; particularly in Australia and South America. Aluminium is a reactive element, and so is not found in nature in the elemental form. Aluminium is a metal, and an amphoteric substance; that is; it reacts with both acids and bases.

- Q: Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: What are the different types of finishes available for aluminum sheets?

- There are several different types of finishes that are commonly available for aluminum sheets. These finishes are applied to the surface of the aluminum to enhance its appearance, protect it from corrosion, and improve its durability. One of the most common types of finishes is the mill finish, which is the natural finish that is achieved after the aluminum has been extruded or rolled. This finish has a smooth and shiny appearance, but it is not as resistant to corrosion as some of the other finishes. Another type of finish is the brushed finish, which is achieved by brushing the surface of the aluminum with a fine abrasive material. This creates a pattern of fine lines on the surface, giving it a unique and textured appearance. Brushed finishes are commonly used in architectural applications and can also help to hide scratches and other imperfections. Anodizing is another popular finish for aluminum sheets. This process involves immersing the aluminum in an electrolytic bath and applying an electric current to it. This causes a layer of aluminum oxide to form on the surface, which provides excellent corrosion resistance and can be dyed in various colors for aesthetic purposes. Powder coating is another commonly used finish for aluminum sheets. In this process, a dry powder is sprayed onto the surface of the aluminum and then heated to form a durable coating. Powder coating is available in a wide range of colors and finishes, including matte, glossy, and textured. Finally, there is the painted finish, which involves applying a liquid paint to the surface of the aluminum. This finish offers a high level of customization, as it is available in virtually any color and can be applied in various patterns and textures. Overall, the choice of finish for aluminum sheets depends on the specific requirements of the application, such as aesthetics, corrosion resistance, and durability. Each finish offers its own unique advantages and can greatly enhance the appearance and performance of aluminum sheets.

- Q: What are the common aluminum sheets and the best ones?

- That depends on what you are doing, and commonly used on 3003 and 5052, the performance is better to use 6061

- Q: Can the aluminum sheets be used in marine environments?

- Indeed, aluminum sheets are suitable for deployment in marine settings. Owing to its exceptional resistance to corrosion, aluminum stands as a favored selection for marine utilization. Unlike its counterparts, aluminum develops a safeguarding oxide layer when it comes into contact with oxygen, thereby inhibiting further corrosion. Consequently, it proves to be the perfect choice for employment in environments saturated with saltwater, where the probabilities of rusting and corrosion are notably elevated. Moreover, aluminum boasts attributes such as its lightweight nature, durability, and an outstanding strength-to-weight ratio, rendering it a fitting option for an array of marine applications, encompassing boat hulls, ship construction, offshore platforms, and an array of other marine structures.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Yes, aluminum sheets can be anodized to enhance their corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

Send your message to us

Aluminum Sheets in Missouri - Color Coated Aluminum Coils for Interior Decoration Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords