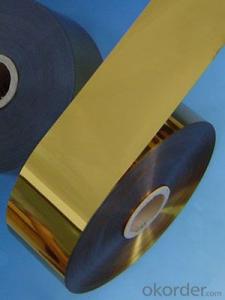

Aluminum Foil Facing Color Metalized PET/LDPE; 12mic MPET + 20mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for methods to clean aluminum foil that has excess oil on it after cooking or food storage.

- <p>To remove excess oil from aluminum foil facing after cooking or food storage, you can follow these steps: 1. Allow the foil to cool down to avoid burns. 2. Use a paper towel to blot and absorb the excess oil. 3. For stubborn oil, you can wipe the foil with a damp cloth or sponge with a mild dish soap. 4. Rinse the foil thoroughly with warm water to remove any soap residue. 5. Dry the foil with a clean towel or let it air dry. If the oil is extremely stubborn, consider using a gentle scrubber or baking soda paste to help remove it. Always check the foil for any damage or wear before reusing it.</p>

- Q: Is it safe to use aluminum foil as a cooking surface? If yes, what kinds of foods are suitable for cooking with aluminum foil?

- <p>Yes, aluminum foil can be used for cooking, but it's important to use it safely. It's suitable for wrapping foods like fish, meats, and vegetables to retain moisture and flavor. It's also used for making packets for steaming or baking, and for lining baking sheets to prevent sticking. However, avoid using it with acidic foods or at high temperatures as it can react with the food or release aluminum into the food. Always use heavy-duty aluminum foil for cooking to ensure it can withstand the heat.</p>

- Q: Is it possible to use aluminum foil as a cooking utensil for stir-frying or sauteing food?

- <p>While aluminum foil can be used in some cooking applications, it is not recommended for stir-frying or sauteing due to its low melting point and potential for tearing. Aluminum foil can melt at high temperatures, which are often used in stir-frying and sauteing, leading to a fire hazard or uneven cooking. Additionally, the foil may tear or puncture easily, releasing aluminum particles into the food, which is not safe. Instead, use proper cookware like non-stick pans or stainless steel for these cooking methods.</p>

- Q: Is it possible to use aluminum foil as a replacement for tin foil in cooking and food preservation?

- <p>While aluminum foil and tin foil are both used for cooking and food storage, they have different properties. Aluminum foil is commonly used for its heat conductivity and is suitable for most cooking and wrapping needs. However, tin foil, which is actually a thin sheet of aluminum coated with a thin layer of tin, is less reactive and can be better for certain applications, especially when preserving the taste and aroma of food. It's generally safe to use aluminum foil as a substitute, but it might not offer the same non-reactive properties as tin foil in all cases. Always ensure that the aluminum foil is food-grade and avoid using it with acidic foods, as this can cause the aluminum to leach into the food.</p>

- Q: Is it possible to enhance the flavor of food by using aluminum foil facing?

- <p>Yes, using aluminum foil facing can help make food more flavorful. It can seal in moisture and steam, which helps to keep the food juicy and tender. The foil also allows for even heat distribution, which can enhance the cooking process and the development of flavors. However, it's important to note that aluminum foil should not be used with acidic foods as it can react and potentially leach into the food. Additionally, for certain dishes, direct contact with the heat source can be necessary for achieving a desired texture or flavor, so the use of foil should be considered based on the specific recipe and cooking method.</p>

- Q: Is it possible to use aluminum foil facing to create a container for holding liquids or powders?

- <p>While aluminum foil facing can be used to create a temporary or makeshift container for storing liquids or powders, it is not recommended for long-term storage due to potential permeability issues. Aluminum foil is not watertight and can allow moisture and air to pass through, which may affect the quality of the stored substances. For liquids, it can also be prone to leaks. It is better to use containers specifically designed for the purpose, made from materials that are impermeable and suitable for the substances being stored.</p>

- Q: What specific safety measures should be considered when utilizing aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid sharp edges that can cause cuts. Avoid using it in direct contact with an open flame as it can melt and release toxic fumes. Do not use aluminum foil with non-stick cookware as it can damage the surface. Keep it away from high heat sources like broilers and never use it to line baking sheets as it can catch fire. Always ensure that any food wrapped in aluminum foil is sealed properly to prevent the foil from coming into contact with heat sources directly.</p>

- Q: This question asks for instructions on how to store food wrap materials after they have been used.

- <p>After using food wrap materials, it's important to clean them properly before storing. Rinse off any food residue with warm water and mild dish soap. Avoid using abrasive materials that could damage the wrap. Once clean, gently pat dry with a clean towel or let air dry. Store the wraps in a cool, dry place away from direct sunlight to prevent degradation. You can use a clean, airtight container or resealable plastic bag to keep them protected and dust-free. Always check for any signs of wear or damage before reusing to ensure food safety.</p>

- Q: Explain the differences between aluminum foil facing and other types of food wrap.

- <p>Aluminum foil facing is a type of food wrap that is made from thin sheets of aluminum, which provides excellent barrier properties against air, moisture, and light. It is often used for cooking, baking, and preserving food. Unlike plastic wraps, it does not stick to food and can withstand high temperatures without melting. Other types of food wraps, such as plastic or cling wraps, are made from polymers and are not heat resistant. They are typically used for short-term food storage and are not suitable for cooking. Paper-based wraps, like parchment or wax paper, are used for baking and providing a non-stick surface but do not offer the same barrier properties as aluminum foil.</p>

- Q: This question asks about the distinction between aluminum foil made from new raw materials and that made from recycled materials.

- <p>Yes, there is a difference between 'virgin' and 'recycled' aluminum foil. Virgin aluminum foil is produced from newly mined bauxite ore and is considered to be of higher purity. It is often preferred for applications requiring high quality and consistency. Recycled aluminum foil, on the other hand, is made from aluminum waste that has been collected, sorted, and reprocessed. It is more environmentally friendly as it reduces waste and energy consumption. However, recycled aluminum foil may have slight variations in thickness and quality due to the recycling process.</p>

Send your message to us

Aluminum Foil Facing Color Metalized PET/LDPE; 12mic MPET + 20mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords