Aluminum Foil Facing 7mic Aluminum Foil+9mic LDPE for Cable Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 212 inch

- Supply Capability:

- 4323221 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

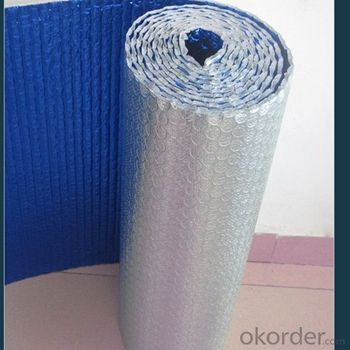

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What specific cleaning procedures should be followed after using aluminum foil facing?

- <p>After using aluminum foil facing, there are a few special cleaning methods to consider. First, remove any leftover food or debris from the surface. If it's a reusable aluminum foil facing, gently wash it with warm soapy water and a soft sponge, avoiding abrasive materials that could scratch the surface. Rinse thoroughly and dry completely to prevent rust. For disposable foil, simply dispose of it according to local waste management guidelines. Avoid using harsh chemicals or extreme heat as they can damage the aluminum foil facing. Regular maintenance will ensure the longevity and hygiene of your aluminum foil facing.</p>

- Q: This question asks about the potential health consequences of consuming food that has been wrapped in aluminum foil and then cooked or heated.

- <p>Eating food wrapped in aluminum foil facing is generally considered safe. Aluminum foil is designed to be food-safe and is approved by regulatory agencies like the FDA for cooking and food storage. However, there are some concerns about aluminum exposure. While the risk is minimal, it's important to note that prolonged, excessive exposure to aluminum could potentially contribute to health issues, although the link is not definitively proven. To be safe, it's recommended to avoid wrapping acidic foods like tomatoes or vinegar-based dishes in aluminum foil, as these can cause the foil to corrode and release aluminum. Additionally, using non-stick or parchment paper as an alternative can help minimize direct contact with aluminum.</p>

- Q: What safety measures should be considered when using aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid cuts from sharp edges. Always use a cutting board when cutting foil to prevent damage to countertops. Avoid using aluminum foil with non-stick cookware, as it can scratch the surface. Do not use aluminum foil in broilers or ovens above 450掳F (232掳C), as it can melt and release toxic fumes. Never use aluminum foil to wrap foods that will be cooked in a microwave, as it can cause sparks and fires. Always ensure that foil is properly secured when used to cover food to prevent it from coming into contact with the heating elements of the oven.</p>

- Q: Is it hazardous to cook acidic or salty foods with aluminum foil?

- <p>Using aluminum foil with highly acidic or salty foods is generally safe, but it's important to use the correct type of foil. Heavy-duty aluminum foil is designed for cooking and is safe for use with acidic and salty foods. However, avoid using aluminum foil with reactive metals, as it can cause a chemical reaction. Always follow cooking instructions and be cautious with prolonged cooking times or high temperatures, as these can potentially cause the foil to break down and release small amounts of aluminum into the food. For best results, opt for non-reactive cookware or use parchment paper or silicone baking mats as alternatives.</p>

- Q: What are the potential health hazards linked to the use of aluminum foil facing?

- <p>The use of aluminum foil facing in construction or insulation can potentially pose health risks. Inhalation of aluminum dust can lead to respiratory issues, and long-term exposure may contribute to neurological problems. There's also a concern about the leaching of aluminum into food when using aluminum foil for cooking or food wrapping, which some studies suggest could be linked to Alzheimer's disease, although this link is not definitively proven. It's important to handle aluminum foil facing with care, ensuring proper ventilation and protective gear during installation to minimize health risks.</p>

- Q: This question asks for methods to store aluminum foil to prevent damage and rusting.

- <p>Aluminum foil is resistant to rusting, but it can still be damaged if not stored properly. To store aluminum foil, keep it in a cool, dry place away from direct sunlight. Use an airtight container or a resealable plastic bag to protect it from moisture and air, which can cause it to oxidize and lose its shine. Avoid stacking heavy items on top of it, as this can cause dents and tears. If you have a large amount, consider using a foil storage box with compartments to keep it organized and protected.</p>

- Q: Is it possible to use aluminum foil with a shiny side as a non-stick surface for cooking purposes?

- <p>Yes, you can use aluminum foil facing as a non-stick surface for cooking. The shiny side of aluminum foil is often used to create a non-stick surface, which can be helpful when grilling or baking to prevent food from sticking to the pan or grill. However, it's important to use it properly to avoid any potential health risks. Ensure that the foil doesn't touch the heat source directly for extended periods, as this can cause the foil to break down and release aluminum into the food. It's also recommended to use heavy-duty aluminum foil for cooking to ensure it can withstand higher temperatures without puncturing or melting.</p>

- Q: What precautions can be taken to prevent burns while using aluminum foil in cooking or baking?

- <p>To avoid getting burned when using aluminum foil for cooking or baking, follow these safety tips: Always handle the foil with utensils or wear heat-resistant gloves. Avoid touching the foil directly after cooking or baking, as it can retain heat. Use heavy-duty aluminum foil to prevent punctures and tears that can cause burns. Keep aluminum foil away from open flames or high heat sources to prevent it from catching fire. Always use caution when removing aluminum foil from an oven or stovetop, and let it cool slightly before handling.</p>

- Q: Explain the various applications of aluminum foil facing in different contexts.

- <p>Aluminum foil facing can be used in various ways depending on the application. In construction, it serves as a vapor barrier to prevent moisture from affecting the insulation. In packaging, it's used for food preservation, providing a barrier against air and light, which helps to keep food fresh. In the automotive industry, it's used for heat reflection and insulation in car engines. It's also used in the manufacturing of reflective materials and in art for creating unique textures and effects. Additionally, aluminum foil facing is utilized in the aerospace industry for heat shielding and in the medical field for sterilization purposes. Each application leverages the properties of aluminum foil, such as its light weight, durability, and heat resistance.</p>

- Q: Explain the distinct characteristics of aluminum foil facing compared to other metal facings.

- <p>Aluminum foil facing is a type of metal facing material that is made from thin sheets of aluminum, known for its light weight, high reflectivity, and excellent heat resistance. It is commonly used in construction for insulation and moisture protection. In contrast, other types of metal facings, such as steel or copper, may offer different properties. Steel facings are often stronger and more durable but can be heavier and less resistant to corrosion without protective coatings. Copper facings are known for their natural resistance to corrosion and can be used in applications requiring antimicrobial properties or high thermal and electrical conductivity. Each type of metal facing has its unique advantages and is chosen based on specific application needs.</p>

Send your message to us

Aluminum Foil Facing 7mic Aluminum Foil+9mic LDPE for Cable Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 212 inch

- Supply Capability:

- 4323221 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords